>2 / >3 W/m*K

Showing all 4 results

Filtri

Tipo di prodotto

- 1 Electrically conductive adhesives

- 1 Gap filler

- 2 Heat-conductive adhesive

Marchio

Tecnologia

Applicazioni

-

- Can be used as a printable PAD

- Can replace the traditional manufactured pad

- Use as a gap filler

- Dispensed or printed through manual or automated processes

- Deposit of features for precise coverage of components

- Lower cost of ownership than manufactured pads

- Excellent thermal performance

- Soft, stress-relieving and shock-dampening

- Reworkable

-

- Polymerization at room temperature

- Long-term performance stability up to 150°C

- Low compression stress

- Maintains upright position (cured or uncured state)

- Controlled volatility of silicone

-

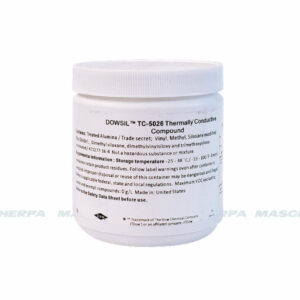

- Solvent-free formulation

- Sliding

- Does not polymerize

- Able to achieve bond line thickness

- Very low thermal resistance

- High thermal conductivity

- Wicks heat away from sensitive components

-

- Extreme electrical conductivity

- Convenient 1-to-1 mixing ratio

- Processing time: 20 minutes

- Cure time: 6 hours at room temperature or 10 minutes at 65 °C (149 °F)

- Creates strong permanent electrical connections

- Polymerization at room temperature

- Without SVHC

- Excellent adhesion to many substratesStorage at room temperature

- Long shelf life

- Strong resistance to moisture, salt water, light bases and aliphatic hydrocarbons