Industry

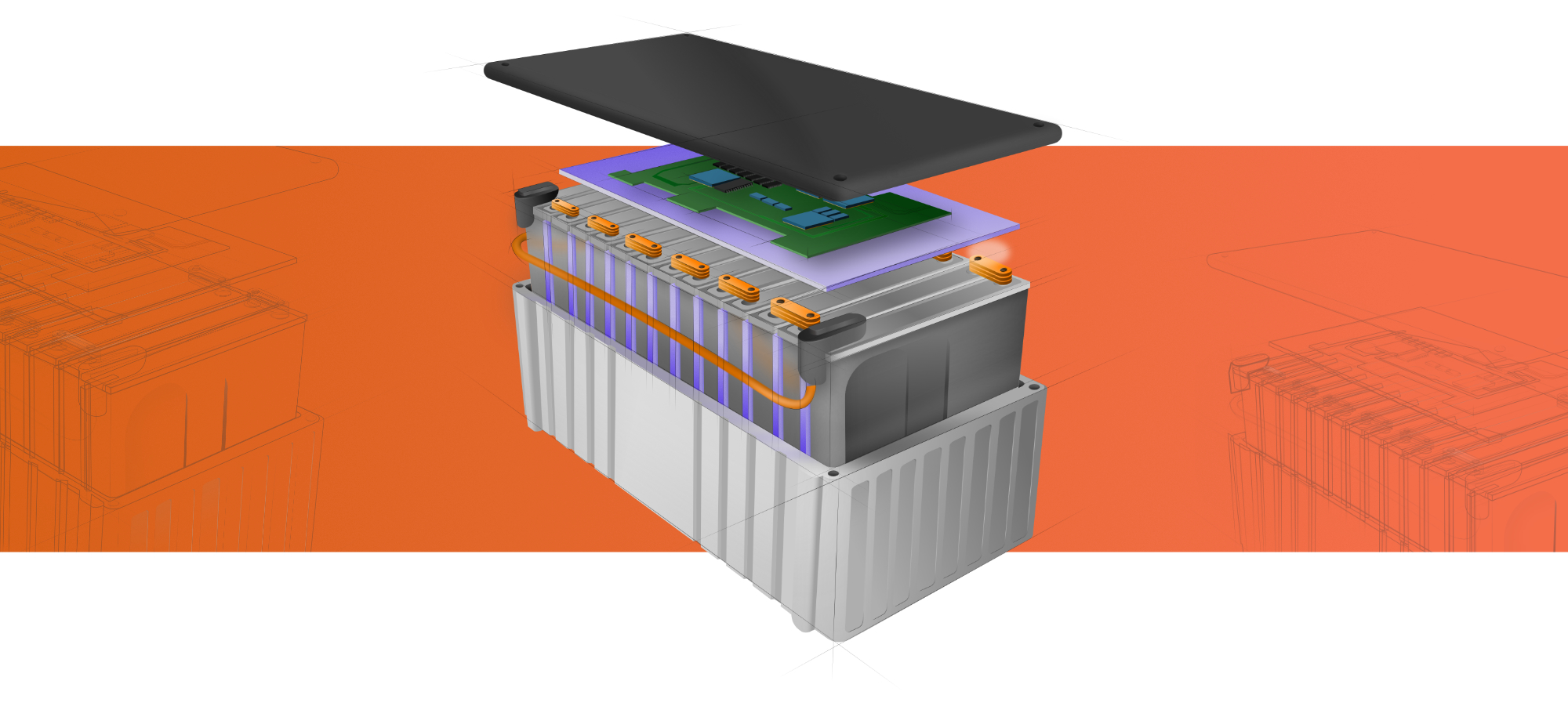

Battery system | E-Mobility

Mascherpa’s E-Mobility thermal management materials, adhesives, sealants and coating technologies can help vehicle manufacturers.

E-Mobility challenges for EV battery systems.

E-Mobility challenges for EV battery systems.

New battery designs are needed to power the electric vehicle revolution. Critical end-consumer perceptions of range anxiety, as well as price and safety concerns, must be addressed through batteries that offer reliable and safe car operation in tandem with fast charging.

Battery designs vary, especially in terms of the type of cells used – manufacturers typically use cylindrical, pouch or prismatic cells. OEMs and Tier 1s face a number of challenges: cost reduction, performance optimization, safety and reliability, and seamless integration into the body. Mascherpa’s thermal management materials, adhesives, sealants, and coating technologies can help vehicle manufacturers address these challenges.

Thermal management

Thermal management in electric vehicles, ensuring that batteries do not overheat, is critical to vehicle safety and battery performance. End-consumer range anxiety can be specifically addressed with technology solutions that provide higher energy density and fast charging, without increasing stress on the battery system. Mascherpa offers a wide range of gap fillers and other thermal interface materials to improve battery pack performance and reliability.

Reliability

EV battery system components require mechanical safety, as well as shock and vibration stability for optimal performance against any indoor or outdoor conditions. Higher energy density batteries with reduced weight are ideal must not compromise their impact resistance in the event of an accident. The safety of energy storage devices is a key concern for manufacturers. This is further accentuated by UL94 and other flame delay compliance standards.

Gap pad

GAP PAD thermal products improve thermal performance and reliability by eliminating air gaps and reducing interfacial resistance. They also offer easy handling of the material.

Thermally conductive adhesives for electronics

Thermo-conductive adhesives have: excellent dielectric properties, excellent weathering resistance, stability over a wide temperature range, good adhesion on a wide variety of substrates, lower stresses on components, and resistance to ultraviolet rays and chemicals. The products can be used for applications in modules, connectors, sensors, PCBs and many more.

Battery Assembly Adhesives

Battery assembly adhesives allow economical and fast assembly of prismatic, cylindrical, or pouch cells.

Continued on e-mobility

Latest articles on the Battery system

Sign up for newsletter to receive upcoming articles