Industry

Electric Drive systems | E-Mobility

Mascherpa supports electric vehicle manufacturers at every stage, optimizing materials to meet the wide range of component requirements for E-Drive

E-Mobility Challenges for e-Drive Systems.

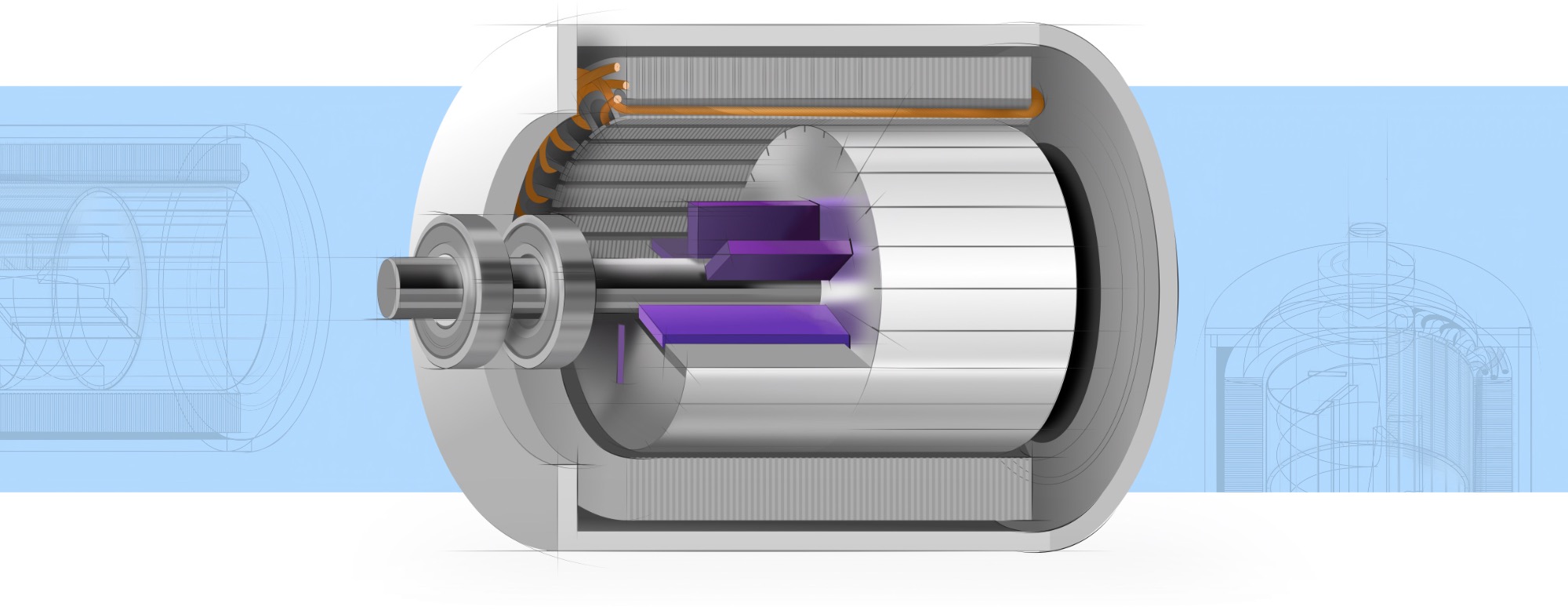

Electric drive systems consist of electric motor, transmission and drive housing, provide the speed and torque to today’s best electric vehicles. E-drive systems require very specific adhesive technologies designed to keep out dust, fluids and other environmental factors that affect the safe and efficient operation of the vehicle.

Mascherpa’s cutting-edge technologies are designed to meet and exceed manufacturers’ requirements for both all-electric and hybrid-electric driving systems. From design to mass production, Mascherpa supports electric vehicle manufacturers at every stage, optimizing materials to meet the wide range of component requirements for E-Drive.

Greases for electric motor bearings

- Thermal potting

- Magnet bonding

- Gasketing

Thermal management

Industry trends toward combining electric motors with power conversion systems and increasing miniaturization of components allow manufacturers to save space and reduce weight. The result is both higher power density and higher risk of engine failure. In order to reduce these risks, electric motors require better thermal management materials, including resins with higher thermal conductivity.

Reliability

Lifetime performance of EV e-drives is a significant challenge for manufacturers. Constant movement and the tendency to improve power density require stronger materials. Mascherpa’s thermal encapsulation and sealing technologies can help increase the reliability of electrical drive systems

Magnet bonding

Araldite structural adhesives are particularly suitable for three steps in the assembly of electric motors:

- Assembly of magnets and lamination stacks,

- shaft and rotor assembly

- Assembly of stator and housing.

Greases for electric motors

Lubricating grease is an essential component because it enables the designer to achieve control of precision, quietness, and feel in a simple and economical way.In fact, through the lubricant, the parts are separated by an adhesive film of grease, which cancels out play and decreases the development of noise and wear.

Thermal potting

Encapsulants protect sensitive electronic components in the electric motor, preserving them from vibration, high temperatures, dust, corrosion and moisture.

Continued on e-mobility

Latest articles on theElectric Drive systems

Sign up for newsletter to receive upcoming articles