Product Type for Industrial Adhesives

Structural adhesives

Learn about the range of structural adhesives and all the solutions to which they can be applied.

Introduction

Structural adhesives are characterized by a great hold that allows them excellent mechanical performance on dissimilar substrates, which is why these adhesives can replace traditional assembly methods such as rivets, screws, bolts, and welds.

Structural adhesives are so called because when they are applied and begin the curing process they create an extremely strong and tenacious bond with the substrate giving a structural contribution to the bonded parts.

Structural adhesives manage to have forces evenly distributed over the entire bonded area; in contrast imagine the strain of a screw in holding two components together where all stress is concentrated at the point of attachment.

Pairing dissimilar substrates

- Structural adhesives can couple dissimilar substrates: for example, aluminum alloy and thermoplastics, metals, and carbon composites; materials that cannot be welded in any way and would yield inferior results if assembled mechanically.

Structural adhesive quality

- The ‘structural adhesive offers designers the possibility of making, by adopting different materials (composites, light alloys, and plastic polymers), lightweight and strong artifacts. Structural adhesives facilitate the integrity and performance of materials because there are no rivet holes and fasteners that can weaken the structure.

- Remember that even though structural adhesives can join extremely dissimilar materials, it is always a good idea to properly prepare the surfaces.

Structural adhesive properties

- They offer mechanical tensile shear performance between 5 and 40 MPa.

- Distribute the applied load over the entire joint area

- They withstand dynamic and fatigue stresses.

- They offer excellent thermal and chemical resistance

Types of structural adhesives

- Epoxy adhesives-Resist high temperatures, weathering and organic substances, offer mechanical performance that can withstand high loads. They are tough and reinforced able to resist dynamic stress, fatigue giving durability of the joint.

- Methacrylic adhesives–They are the ideal solution for bonding thermoplastics, advanced composites and industrial materials, have inherent ability to pre-treat materials at low surface energy, often no surface treatment is required.

- Polyurethane adhesives-They are very versatile, ranging from flexible to semi-rigid capable of meeting broader technical requirements. They are tough and reinforced able to withstand dynamic stress, fatigue giving durability of the joint.

- Acrylic adhesives-These are a class of thermoplastic adhesives distinguished by their excellent resistance to light, moisture and weathering.

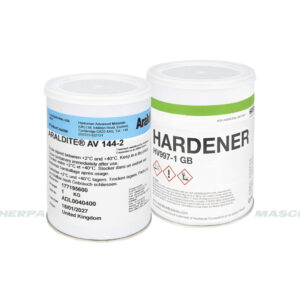

Products

All products for the Structural adhesives

Filter products by their attributes: brand, technology, applications…

Reference categories for Structural adhesives

Continue browsing the Mascherpa site

Latest articles on the Structural adhesives

Sign up for newsletter to receive upcoming articles

Read PDFs on the Structural adhesives

- There are no PDFs yet for: Structural adhesives, ask the expert if you need an SDS or Data Sheet

Industries

Select your product starting with the relevant industry.