Applications for industrial lubricants

Lubricants for gaskets and O-rings

Find the ideal lubricant for gaskets and O-rings. Learn about the benefits, features and get expert advice from Mascherpa experts.

Introduction

Choosing an appropriate lubricant for seals and O-rings is crucial to ensure consistent and long-lasting operation. Inadequate lubricant compatibility can cause undesirable changes in physical properties, such as swelling, shrinkage, and changes in hardness, which can lead to damage and failure. To avoid such problems, Mascherpa technicians offer expert advice to help you select the specific lubricant for your needs.

Benefits of using lubricants for gaskets and O-rings

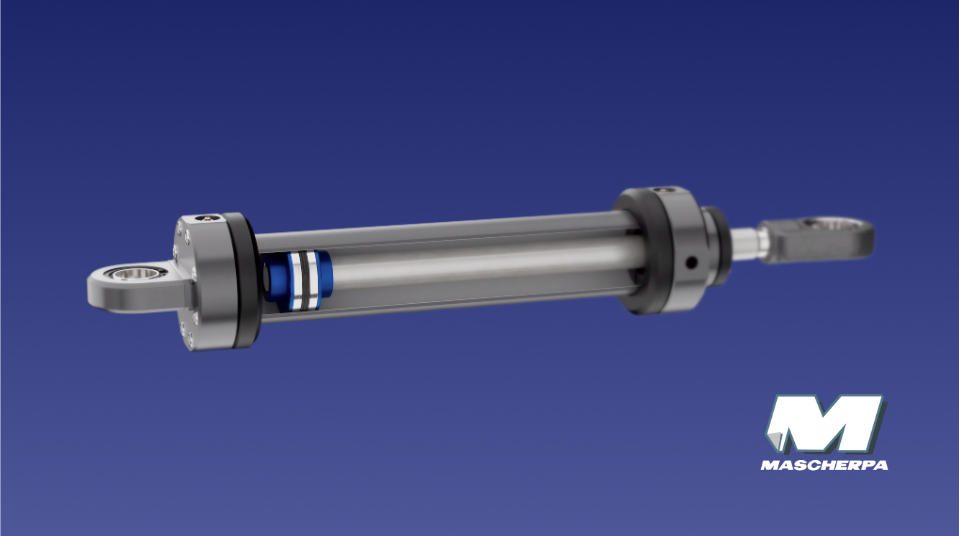

- Lubricants specially formulated for gaskets and O-rings offer numerous advantages. First, they facilitate assembly, reducing mechanical wear and improving the sealing effect. This is especially important because O-rings are compressed during the assembly of two or more parts to create a sealing gasket. Using the correct lubricant can help achieve a better seal due to the sealing power of some lubricants.

Characteristics of seal and O-ring lubricants

- Lubricants for gaskets and O-rings must possess specific characteristics to ensure optimal performance. These greases must be water-resistant and able to provide high flow over a wide temperature range. They must also be compatible with the elastomers and plastics used in applications, ensuring maximum effectiveness and durability of seals and O-rings. These lubricants are used to improve the mechanical properties of rubber and elastomers, such as abrasion resistance, elasticity, and flexural strength. In addition, they can thus prolong the life of rubber parts and elastomers.

Certifications and approvals

- Lubricants offered by Mascherpa are formulated and manufactured using only suitable and certified raw materials. These lubricants can be approved according to international standards, such as NSF H1 approval for food contact, WRAS approval for drinking water contact, DVGW approval for household gas, and BAM approval for oxygen contact. These certifications testify to the high quality and compliance of the lubricants with the specific requirements of different applications.

Products

All products for Gaskets and O-rings

Filter products by their attributes: brand, technology, applications…

Reference categories for Gaskets and O-rings

Continue browsing the Mascherpa site

Latest articles on Gaskets and O-rings

Sign up for newsletter to receive upcoming articles

Lubricants for the mining and extraction industry

Seal grease: the role of lubrication in the durability of O-rings and elastomers

Reliable and Durable Lubricants for the Railway Industry

Read PDFs on Gaskets and O-rings

- There are no PDFs yet for:

Gaskets and O-rings , ask the expert if you need an SDS or Data Sheet