Brands

Chemours

Special lubricants

Chemours, a specialized chemical company

Chemours is a specialty chemical company, originally a division of DuPont, which was founded in 2015.

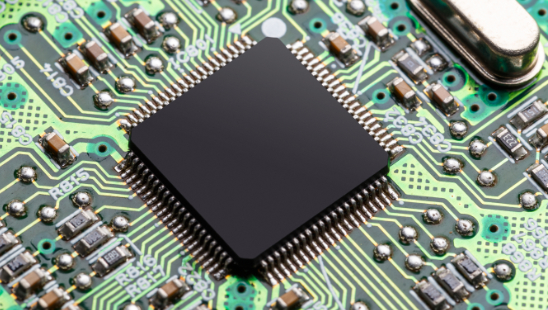

The company is known for its wide range of innovative chemical solutions and advanced materials that are used in various industries.

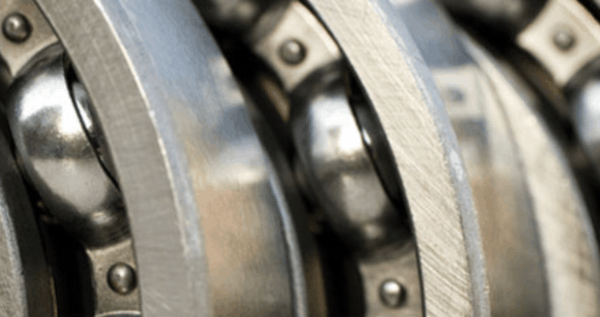

Among its flagship products are the high-performance lubricants in the Krytox™ line. Krytox lubricants are made using a family of synthetic perfluoropolyether (PFPE) oils. These oils are characterized by their nonreactivity, wide temperature stability and resistance to various aggressive chemicals and solvents. Chemours’ Krytox™ lubricants are often used in industries and applications where traditional lubricants might fail due to extreme conditions.

Chemours lubricants for every application

- Chemours’ Krytox™ lubricants find application in a wide range of industries, including aerospace, automotive, electronics, chemical, pharmaceutical and more. They are used in areas such as bearings, valves, seals, o-rings and other components where lubrication is essential for smooth operation.

Products

All products Chemours

Filter products by their attributes: brand, technology, applications…

Latest articles on: Chemours

Sign up for newsletter to receive upcoming articles

Krytox valve lubricants: durability and reliability

Chemours analyzes the restriction impact of REACH on PFPE lubricants

The many benefits of Krytox® will amaze you

Krytox 227 : special grease in glass tempering furnaces

Read PDFs on Chemours

- There are no PDFs yet for:

Chemours , ask the expert if you need an SDS or Data Sheet

Industries

Discover the industries of reference for Chemours