Safety and performance in food machinery:

choosing the right H1 lubricant is essential

Download our technical guide and discover winning strategies to successfully pass a safety audit and choose the ideal supplier for better performance of your food machinery.

Download the technical guide now

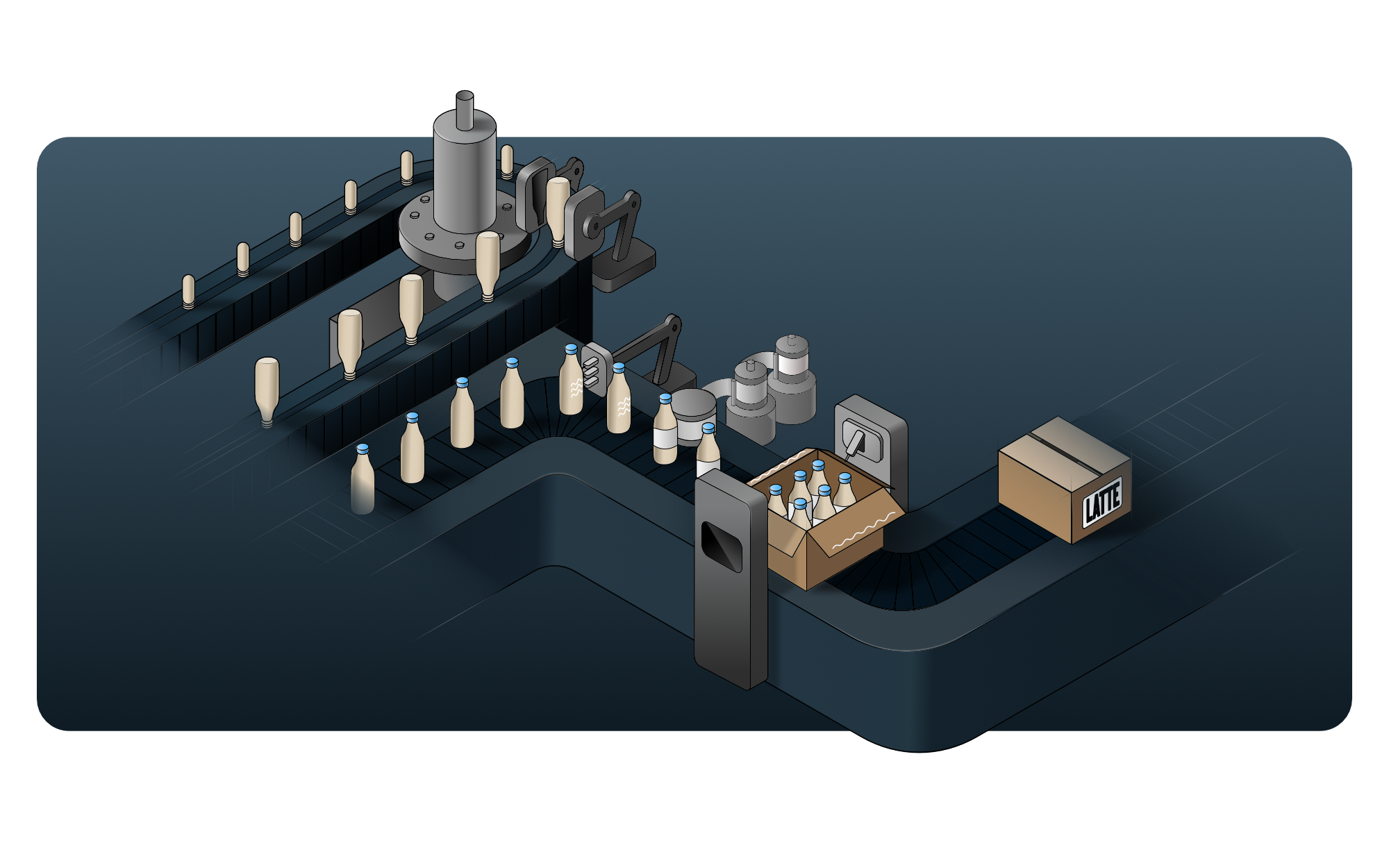

Brescia Milk Plant x Mascherpa

Find out how we implemented our products on the blow molding machine andlabeling machine in the production cycle of Centrale del Latte di Brescia.

”We needed to get important productions for the Brescia Milk Plant. Mascherpa products provided us with safety and efficiency.

Raffaele BombardieriTechnical Maintenance Director

Lubricants in the Food Industry: the challenges of the sector and how to tackle them

The food industry often imposes strict controls and rigid standards for the lubrication of food machinery (NSF, Halal, Kosher, ISO, etc.). For this reason, it is crucial to know the strategies to best address them.

But what are the main challenges for food-grade lubricants?

- Risks of food contamination and machine downtime: inadequate lubrication can compromise production, leading to consequences such as product recalls, fines, and reputational damage.

- Preparation for a food safety audit: failing to comply with standards can lead to fines and production shutdowns. Being ready with all NSF and ISO certifications is essential to avoid further penalties.

- Choosing the right supplier: relying on an expert partner allows for improved production efficiency and ensures quality technical support.

Download our exclusive guide "Complete Guide to Lubricants for the Food Sector" now

Our guide delves into the most critical challenges of lubrication in food machinery and provides practical solutions to ensure safety, regulatory compliance, and production efficiency. From managing contamination risk to certification standards, this document is an indispensable resource for food industry professionals.

If you want to delve deeper into topics concerning the selection of the best supplier for your lubricants and the fundamental steps to prepare for food safety audits, download the dedicated guides.

What is the right food lubricant for your plant?

When it comes to safety and performance in the food industry, choosing the right lubricant is essential. With leading brands like Petro-Canada (PURITY™ FG and REFLO) and Suniso, Mascherpa offers certified solutions that protect plants, reduce downtime, and ensure maximum reliability.

A product with many applications. A product for every sector of the food industry. A product 100% guaranteed by food certifications.

One product. Many applications.

Petro-Canada PURITY™ FG greases and oils are designed to ensure high performance and safety in the food and packaging industries. Resistant to high temperatures, wear, and contamination, they offer reliable lubrication that extends plant life and reduces downtime. NSF certified, they easily integrate into HACCP and GMP programs, ensuring compliance with the strictest safety standards.

PURITY™ FG GREASES

PURITY™ FG FLUIDS

Industries

Mascherpa supports the food industry by providing lubricants for meat and poultry processing, animal feed production, grain and oilseed milling, as well as fruit and vegetable preservation. It is also a trusted partner for the beverage and confectionery sector, covering dairy, sugar, confectionery production, and seafood processing.

The world of baking and packaging also benefits from its solutions, with applications in bakeries, corrugated packaging production, and containers. Finally, Mascherpa, together with partner Petro-Canada, also operates in water treatment, contributing to the efficient operation of dedicated facilities.

With a constant commitment to quality and safety, Mascherpa ensures timely and reliable supplies to help businesses operate at their full potential.

Certifications

Thanks to a fully integrated supply chain, Petro-Canada Lubricants ensures consistent, high-quality products with reliable deliveries worldwide. PURITY™ FG lubricants meet strict industrial standards for food safety and productivity, being registered with NSF for various uses, including incidental food contact and heat transfer.

Certifications include ISO 9001, ISO 14001, and ISO 21469, as well as Kosher Pareve and Halal. PURITY FG products integrate into HACCP plans and GMP programs.

Why download our guide?

Prepare for audits

Ensure you successfully pass every inspection with the best practices for preparing for food-grade lubricant audits

Choose the right supplier

Rely on a strategic partner offering certified products and specialized technical support

Avoid accidental contamination

Discover certified H1 lubricants compliant with international regulations.

Reduce downtime: stay informed about advanced strategies and solutions for production efficiency.

Mascherpa: food-grade lubricants for every stage of food production

For over 120 years, Mascherpa has been the benchmark for lubrication in the food industry. Thanks to our experience, we support professionals in choosing the best certified lubricants to ensure maximum safety, operational efficiency, and regulatory compliance.

The lubricants we provide are designed to meet the needs of every stage of food production, ensuring optimal performance even in complex operating conditions.

We offer specific solutions for ammonia compressors, air compressors, refrigerant compressors, hydraulic oils, food-grade lubricants, thermal fluid systems, gear and reducer oils, ensuring protection from wear, friction reduction, and resistance to high temperatures and frequent washdowns.

We share with Petro-Canada a guarantee on the use of lubricants. We commit to repairing devices or replacing parts that are damaged due to defects in Petro-Canada lubricant, provided the lubricant has been used in accordance with the instructions provided by us and the device manufacturer. It’s more than just a guarantee, it’s a commitment.

Put us to the test: at your next oil change, switch to PURITY FG.

Discover adhesive solutions for labeling and packaging

Learn how reliable food packaging starts with choosing the right adhesive. Certified hot melts improve label adhesion and packaging sealing, reducing waste and optimizing production.

Download our exclusive guide "Complete Guide to Lubricants for the Food Sector"

Fill out the form to receive our guide in your email