Krytox™ 227 FG Corrugator grease: improved lubrication of corrugating machines

Mascherpa guarantees the distribution of lubricants that meet the most stringent and specific requirements. Our lubricants are also used and approved by many machine manufacturers (OEMs) and component suppliers.

The customer’s request

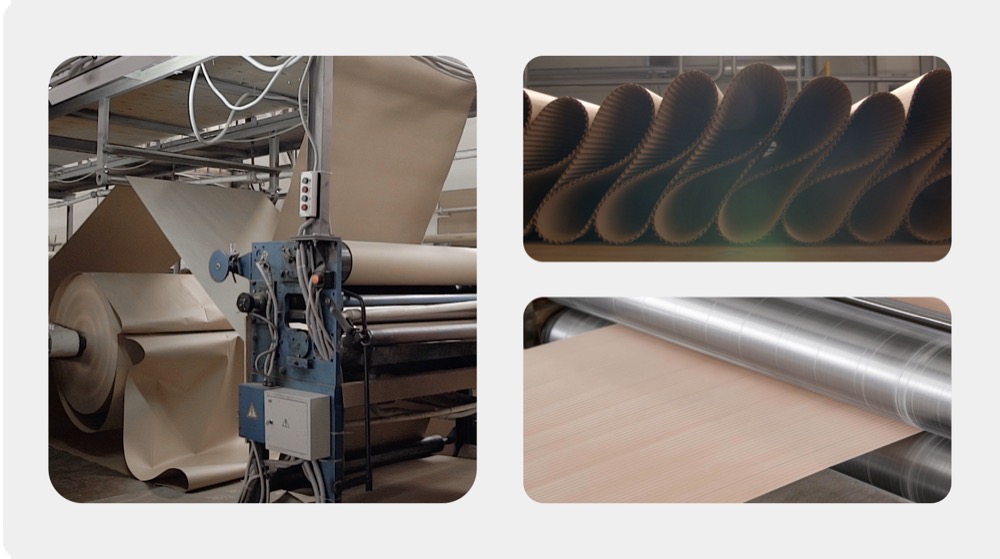

Corrugator production machines require specific and efficient greases. One of our corrugator manufacturing customers, thanks to the Krytox™ 227 FG Corrugator product, reduced the required maintenance cycle by 50 percent to minimize production downtime.

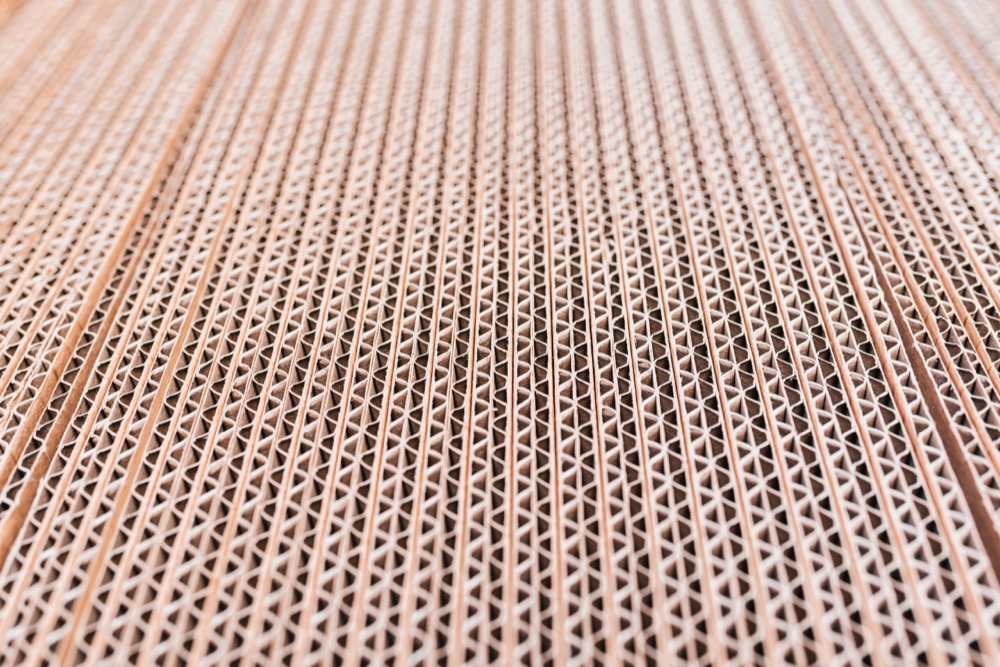

The request made to Mascherpa included a corrugator grease that could provide efficient lubrication despite the complex operating environment of the application. In particular, the grease had to withstand operating temperatures of 195-200 ̊C, not leak, and withstand the high load and speed of the corrugator. In addition, the lubricant had to be compatible with metals and elastomers normally used in corrugated board production lines and not cause carbon residue buildup.

The Solution: Krytox™ 227 FG Corrugator Grease

Since time immemorial, the Krytox™ lubricants we distribute have been the industry standard for durable lubrication of steam-heated corrugator and preheater rollers operating under very high thermal conditions.

In fact, after switching to Corrugator Krytox™ 227FG corrugator grease, the customer was able to schedule equipment maintenance every six months, instead of every three months, without experiencing bearing failure.

Krytox™ 227FG Corrugator is compatible with most commonly used metals and elastomers. It offers long-term wear resistance and thermal stability. In addition, Krytox™ 227FG Corrugator is NF135660 registered and NSF H-1 safe for incidental food contact.