Key points of the article

- A refrigeration system shutdown involves costs well beyond repair: it includes production, energy and product losses. The compressor lubricant is a strategic factor to avoid them.

- Ammonia compressors require lubricants that are stable, compatible, effective at low temperatures and resistant to extreme thermal cycles.

- The REFLO™ range from Petro-Canada offers high-performance mineral and synthetic solutions capable of reducing maintenance, consumption and failures.

- REFLO products guarantee pumpability down to -35°C, minimal solubility in ammonia and long life even in severe or two-stage systems.

- Mascherpa distributes the REFLO™ range in Italy with dedicated consulting, supporting companies in choosing the most suitable lubricant.

When a refrigeration system stops, the cost is not just that of repair: but also production downtime, product loss and uncontrolled energy consumption. In this case, therefore, compressor oil is not a detail, but a strategic component.

Designed to work in critical conditions, ammonia refrigeration compressors require lubricants capable of ensuring smooth flow even at -35°C, resisting extreme thermal cycles and not interacting with ammonia.

The REFLO™ range from Petro-Canada Lubricants, distributed in Italy by Mascherpa, meets these needs with a complete portfolio of solutions: synthetic and mineral oils with very high stability, designed to improve performance, reduce maintenance and protect compressors in the long term.

Index

- Superior performance for ammonia refrigeration compressors

- Reduced maintenance, greater operational reliability

- REFLO range overview: tailored performance for every need

- REFLO Synthetic 68A and REFLO XL: efficiency even in extreme conditions

- Longer life. Lower cost. An investment that pays for itself

- Conclusion: lubricants tailored to refrigeration needs

Superior Performance for Ammonia Refrigeration Compressors

Ammonia refrigeration compressors are widely used in commercial and industrial applications for their efficiency and sustainability. However, the presence of ammonia imposes specific requirements on the lubricant: reduced solubility, compatibility with seals, low foaming tendency and thermal stability.

REFLO A lubricants are formulated precisely to meet these needs:

- Ultra-pure base oils and specific inhibitors against oxidation and corrosion

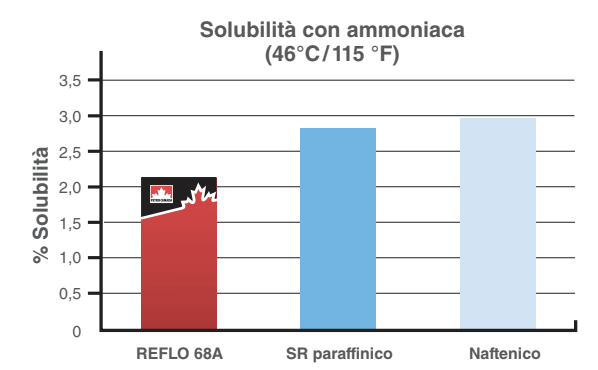

- Minimal solubility in ammonia to reduce oil consumption and ensure greater efficiency

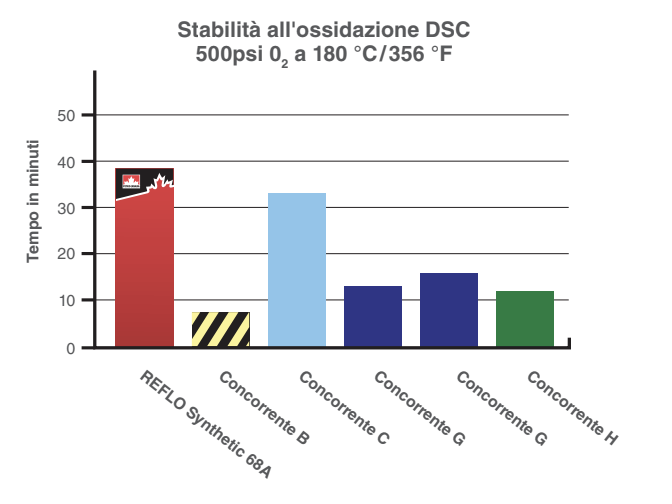

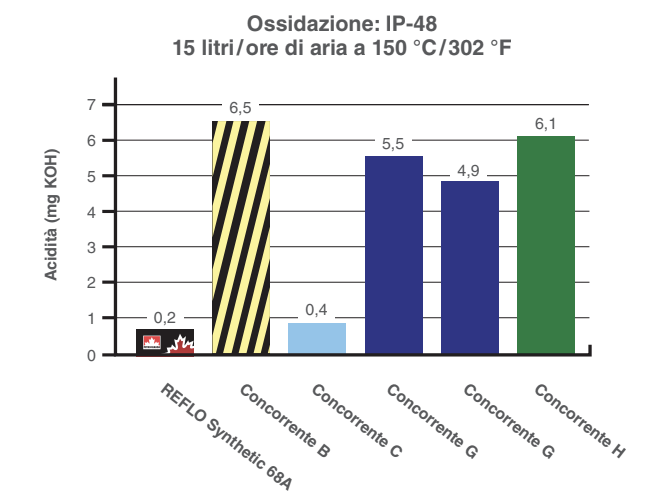

- High oxidation stability even at elevated temperatures

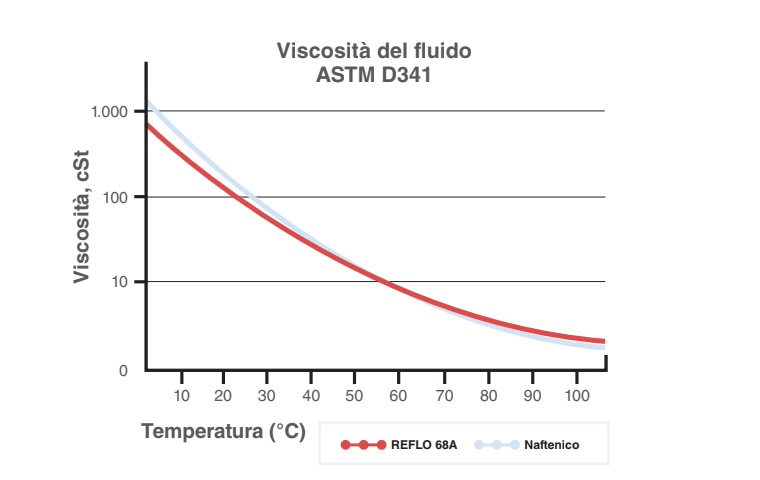

- High viscosity index, which ensures protection over a wide temperature range

- Absence of aromatic substances, which can compromise seals

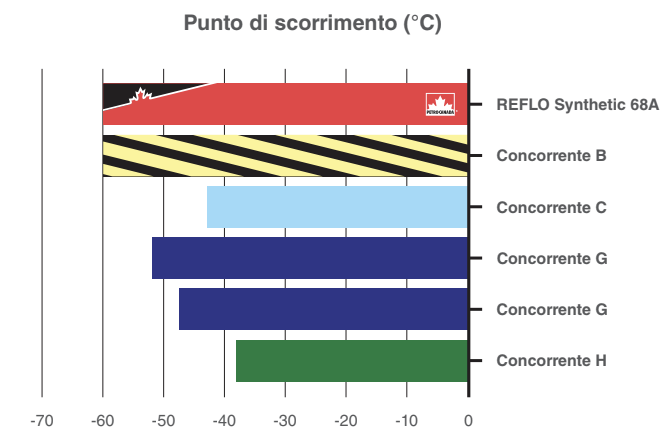

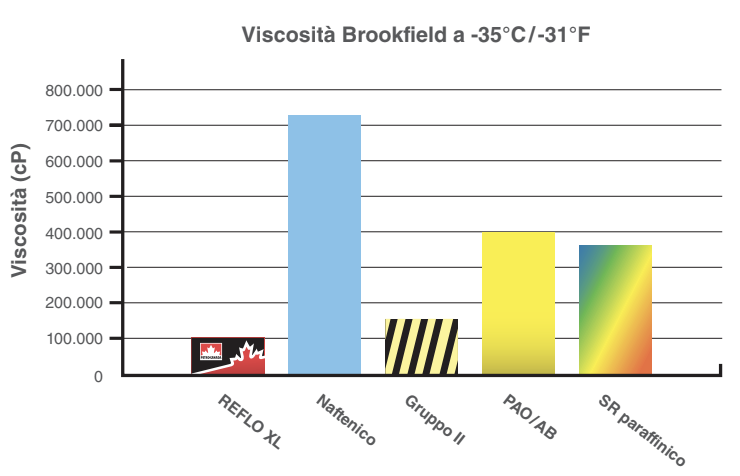

Fluidity at low temperatures is another distinctive factor: REFLO 68A guarantees constant pumpability down to -35°C, surpassing most direct competitors

Reduced Maintenance, Greater Operational Reliability

REFLO A allows companies to reduce downtime by up to 80%, minimize top-ups, and extend compressor service life thanks to:

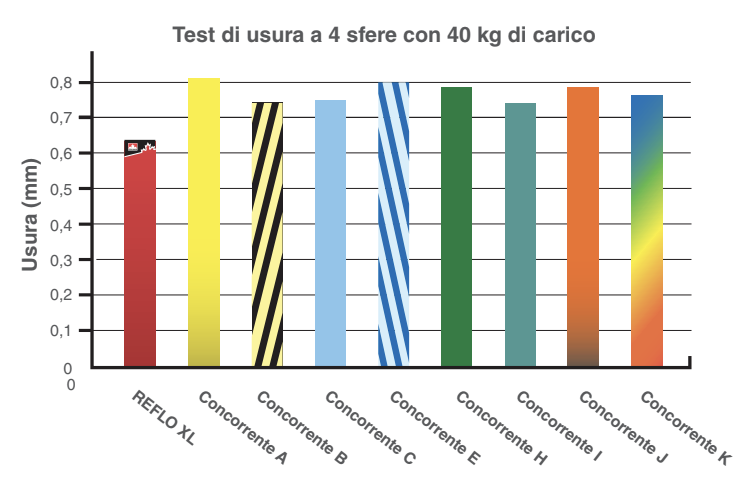

- Superior protection under high loads

- Reduced formation of deposits and residues

- Controlled volatility to reduce consumption

Furthermore, the entire REFLO line is:

- Approved by major compressor OEMs

- NSF H2 certified for food plants (without direct contact with the product)

- Non-toxic, suitable even for critical environments

REFLO Range Overview: Tailored Performance for Every Need

Petro-Canada has developed a complete range of refrigeration compressor lubricants capable of covering different application needs, from the most standard to the most extreme conditions. Each formulation meets rigorous criteria for performance, reliability, compatibility and durability over time. Here is a summary of the main products:

REFLO A

High-quality mineral lubricant designed specifically for ammonia refrigeration compressors. It stands out for:

- Excellent pour point, which ensures fluidity even at low temperatures

- Superior viscosity index compared to naphthenic oils (less thinning at high temperatures)

- Lower solubility in ammonia, to reduce oil loss in the refrigerant cycle

REFLO Synthetic 68A

Fluid synthetic based on PAO/alkylbenzene, designed for:

- Extremely low evaporator temperatures (below -50°C)

- Blast chillers, high-efficiency systems and two-stage compressors

- Excellent oxidative stability and reduced residue formation

- Less absorption by ammonia, lower consumption

REFLO XL

Multicomponent synthetic lubricant, designed for systems subject to severe loads and long duty cycles:

- Very low pour point to ensure pumpability even below zero

- Superior performance compared to traditional Group II oils

- Excellent anti-wear properties and integrated seal treatment

REFLO CFC

Solvent-refined naphthenic oil for legacy systems with chlorinated refrigerants (e.g. Freon, Genetron) or systems where seal replacement is not possible. It guarantees:

- Compatibility with old systems

- Good low-temperature performance

- Reliability and safety in partial replacement

REFLO Synthetic 68A and REFLO XL: Efficiency Even in Extreme Conditions

For applications with very low evaporator temperatures or with particularly severe thermal cycles, Petro-Canada offers the synthetic versions of the REFLO range:

REFLO Synthetic 68A

- Formula based on PAO/Alkylbenzene

- Excellent thermal and oxidative stability

- Reduced absorption by ammonia

- Extends seal life and reduces leaks

Recommended for:

- Two-stage compressors

- Blast chillers

- Systems with evaporator temperatures below -50°C

REFLO XL

- Advanced synthetic blend

- Better pour point compared to Group II products

- Exceptional anti-wear properties for reciprocating compressors

- Low foam formation and high oxidation stability

From Brookfield viscosity and oxidation stability tests, the REFLO range consistently positions itself above the competitor average, offering greater protection and less degradation at low temperatures.

Direct testimonials confirm tangible results: consumption reduced by up to 90%, filters that no longer require frequent replacements and more efficient compressors in the long term.

Longer life. Lower cost. An investment that pays for itself

The choice of REFLO lubricants brings concrete and measurable benefits over time. Thanks to the winning combination of durability, efficiency and reliability, companies reduce:

- the number of extraordinary maintenance interventions

- unplanned machine downtime

- oil and energy consumption

- wear of mechanical components

It is a technical choice that translates into a real economic advantage.

Conclusion: Lubricants Tailored to Refrigeration Needs

The choice of compressor oils is a strategic element in the design and maintenance of refrigeration systems. REFLO compressor lubricants offer an excellent balance between efficiency, protection and sustainability, drastically reducing operating costs and ensuring high performance even in extreme conditions.

Mascherpa supports technicians, designers and maintenance managers in choosing the most suitable lubricant for their system, with consulting support and certified products for every application need. Contact our experts for personalized consulting on refrigeration compressor lubricants.