WHY LUBRICATE THREADED CONNECTIONS WITH MOLYKOTE

Threaded connections offer several advantages, including convenient disassembly, repeated use of a screw, and safe reassembly. However, in order to enjoy these benefits without running into problems related to the equipment and its reliability, proper lubrication is important.

TO PREVENT:

- Inconsistent coefficients of friction, resulting in inconstant bolt tension

- Stepwise advancement

- Tensocorrosion

- Contact

- Wear

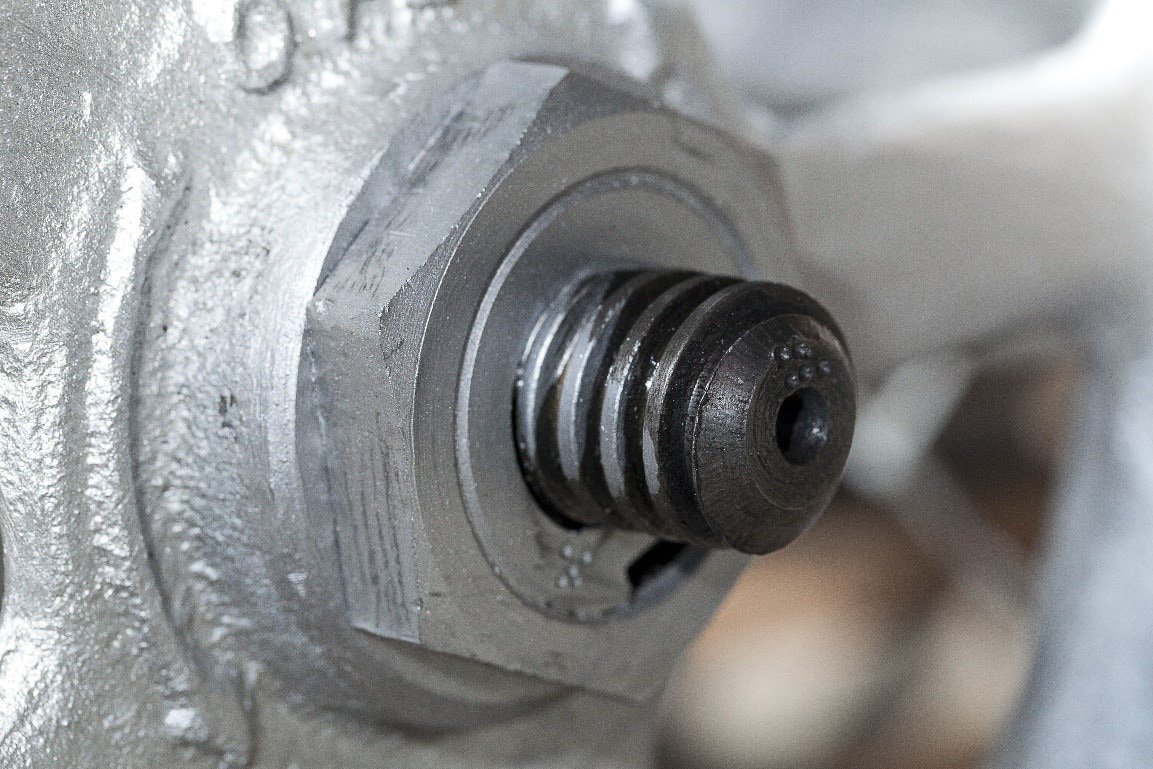

- Gripping

Molykote® brand lubricants help threaded connections function properly, both during initial assembly and in all subsequent disassembly operations. In fact, they are specially formulated to withstand harsh conditions, multiple service temperatures, the stresses of high loads, salt spray and other pollutants.

DEFINITION OF MALFUNCTION MECHANISMS

Inconsistent coefficients of friction (µ) – A high µ of the mating surfaces (head, nuts, shank and threads) can cause the screw torque to increase and the clamping force to decrease. – Low µ of mating surfaces can cause excessive bolt elongation.

Jerky advance The difference between static and kinetic friction when two surfaces are in contact.

Tensocorrosion At high temperatures, sulfur is deposited at grain boundaries, causing high stress points. Sulfur then combines with nickel (from steel alloys) to form sulfide crystals that grow, increasing stress and creating larger and larger cracks.

Contact When vibration leads to wear of oxide layers, oxide particles clog internal spaces, causing seizure.

Wear During contact, the oxide layer of threaded materials peels off. The asperities move from side to side and then break, ruining the surface and preventing disassembly.

Seizing Due to contact, oxide-free surfaces cold weld under extremely high pressure, preventing disassembly. Reducing stress corrosion as well as hydrogen and solder embrittlement

THE BENEFITS OF PROPER LUBRICATION

Molykote lubricants serve to reduce friction and wear, protect against corrosion, and dissipate heat.

The use of carefully selected lubricants prevents common causes of malfunctions related to threaded connections. Here are some of the main benefits of proper lubrication:

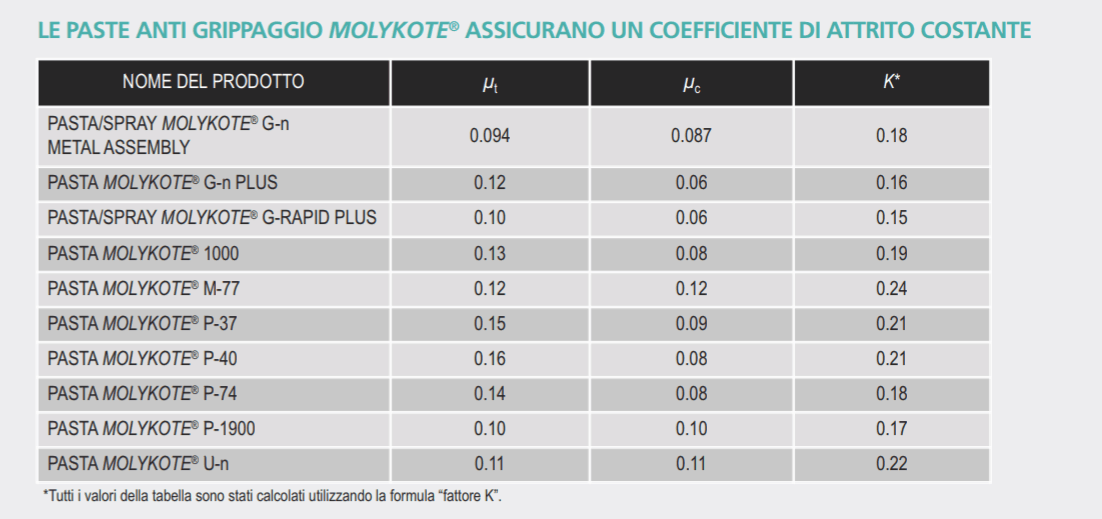

- Provide a constant coefficient of friction, µ

- On mating surfaces, this allows designers and applicators to minimize the difficulty of obtaining adequate connector preload forces and torque specifications

- Limits the effects of temperature and load changes, reducing the chance of fatigue failure

- Creating barriers between substrates and the oxygen layer

- Prevents unwanted scale formation on thread surfaces

- Create protective layers on mating surfaces

- Decreases the effects of oxide layer depletion, reducing contact, wear, seizure and fracture

- Reduces exposure to corrosive, hydrogen-rich and low melting point metal environments