Product Type for Electronics

Thermally conductive materials electronics

Learn about all Mascherpa’s solutions of thermally conductive materials for the thermal interface of an electronic circuits.

Why do I need a thermal interface material.

Electronic devices create heat, this heat slows down the speed of the device and over time will degrade the component, thus affecting its performance.

With greater miniaturization of systems and higher circuit density, current electronics generate large amounts of heat. This trend, will continue to require the removal of this excess energy, which will be even more critical for future applications. If the heat is not absorbed and dissipated, the life and reliability of the electronics will be reduced.

Heat is transferred from a component to its surroundings. The rate of heat loss will increase with the surface area of the component; a small device producing 10 watts will reach a higher temperature than a device of similar power with a larger surface area.

Heatsinks

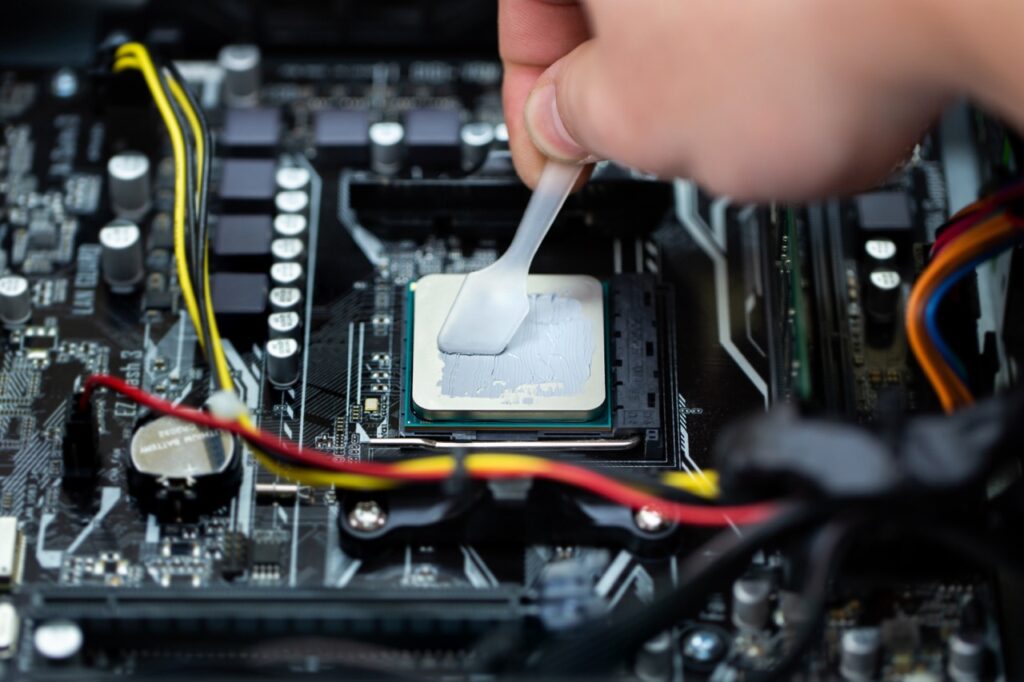

- Heat sinks can be designed to offer greatly increased surface area to maximize heat dissipation, but nevertheless in order to ensure full contact between the heat sink and the component, only through thermal interface materials will the maximum degree of thermal dissipation be achieved.

Purpose of thermally conductive materials

- Metal surfaces, even when thoroughly polished, always show some roughness. Therefore, it can be inferred that when two metal surfaces, such as those between the heat sink and the component are placed together, there will always be small air spaces between the two surfaces.

- Thermal interface materials are used in such gaps to fill the air spaces and ensure complete contact between the two surfaces, improving the efficiency of heat transfer.

Expert Mascherpa

With 120 years of experience in electronic protection, our experts are ready to share their know-how to help you find the perfect solutions.

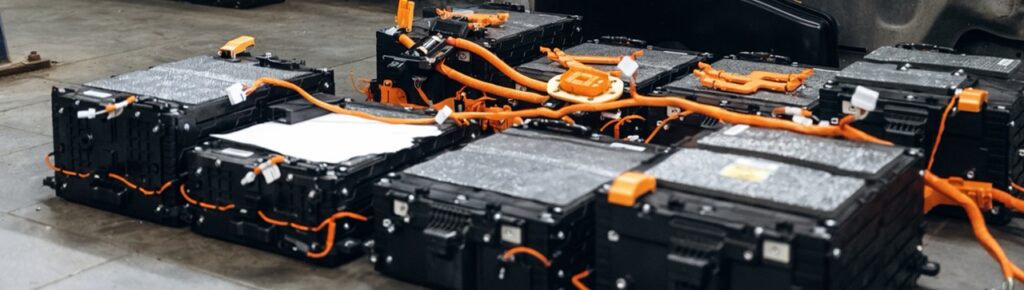

E-Mobility – Thermal Management for Batteries in Electric Vehicles

Battery Thermal Management – Watch the video

Products

All products for the Thermally conductive materials

Filter products by their attributes: brand, technology, applications…

Reference categories for the Thermally conductive materials

Continue browsing the Mascherpa site

Latest articles on the Thermally conductive materials

Sign up for newsletter to receive upcoming articles

Electrically Conductive Epoxy Paint and Adhesives: Various Applications

Thermal management: thermal management in electric vehicle batteries

Thermally Conductive Encapsulants: Thermal Management Guide

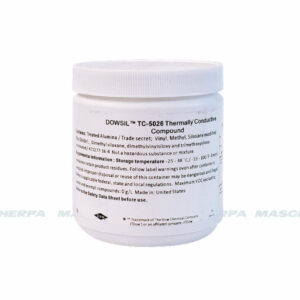

DOWSIL TC-5960: thermal conductive paste against thermal runaway

Advanced thermal management for EV batteries

MG Chemicals: protection and bonding for electronics

DOWSIL TC-4530 CV Gap Filler: E-mobility innovation

Read PDFs on the Thermally conductive materials

- There are no PDFs yet for: Thermally conductive materials, ask the expert if you need an SDS or Data Sheet

Industries

Select your product starting with the relevant industry.