Applications for industrial lubricants

Diathermic oils

Heat transfer systems (diathermic oils) are designed to transport thermal energy away from a heat source by means of a diathermic oil. Systems are designed and components are sized around the physical properties of a new, uncontaminated fluid. The ability of a system to maintain its performance depends on knowing how to keep the fluid in good condition.

Introduction

The obvious challenge for operators is that the diathermic oil-the lifeblood of the system-is almost as good as new; without proper care, the surfaces where heat exchange occurs will become dirty, thus increasing the energy required to maintain temperature, decreasing productivity.

Thermal oil maintenance

- When fluid degradation occurs, its initial properties will change and continue to change as the severity of degradation increases.

- Although no expert can keep diathermic fluid fresh forever, system operators can certainly prolong the preservation of fluid properties by avoiding common threats of degradation and selecting a better fluid for the application.

- In addition to proper system maintenance, one of the most effective control measures an operator can take to maximize fluid life is to select the correct fluid.

The best diathermic oils

- There are a myriad of oils on the market, typically synthetic or mineral, each with its own chemical and performance profile that makes it more or less suitable for a specific processing application.

- Our diathermic oils are 99.9 percent pure oil-based obtained by the patented “Hydro-Treatment” system, which is a process designed to remove impurities.

- They maintain stability and resistance to ‘oxidation and have a significantly longer service life than other mineral oil-based products on the market.

- Better oxidation resistance means cleaner, more efficient systems and lower oil additions (lower consumption).

Products

All products for the Diathermic plants

Filter products by their attributes: brand, technology, applications…

Reference categories for Diathermic plants

Continue browsing the Mascherpa site

Latest articles on the Diathermic plants

Sign up for newsletter to receive upcoming articles

Condat hydraulic fluids and technical greases for steel mills

The importance of proper lubrication of cranes

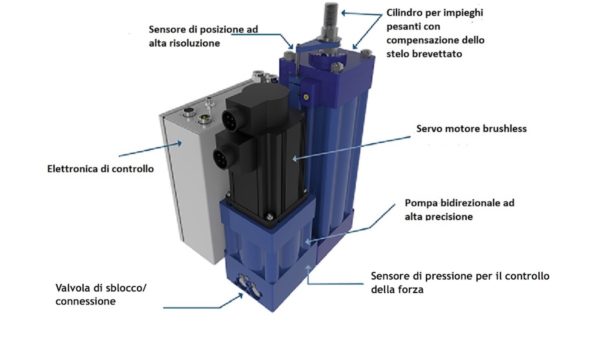

Kyntronics: Electrohydraulic actuators

Read PDFs on Diathermic plants

- There are no PDFs yet for:

Diathermic plants , ask the expert if you need an SDS or Data Sheet