Industry

Advanced Driver Assistance Systems | E-Mobility

ADAS, Advanced Driver Assistance Systems, are the key components of this new frontier of E-Mobility.

E-Mobility challenges for ADAS systems

The automotive industry is changing rapidly and with the introduction of innovative vehicles resulting in safer and more efficient transportation. ADAS, Advanced Driver Assistance Systems, are the key components of this new frontier in mobility, safety and connectivity, and include a wide range of sensors, cameras and connectivity features. Mascherpa is at the forefront of developing advanced materials that are essential for these components.

Today, semi-autonomous vehicles are already on our roads, and fully autonomous vehicles are rapidly becoming a reality. Current adoption rates are expected to grow dramatically in the coming years as the proliferation of ADAS continues throughout the automotive industries and new technologies offer greater levels of safety behind the wheel.

Connectivity

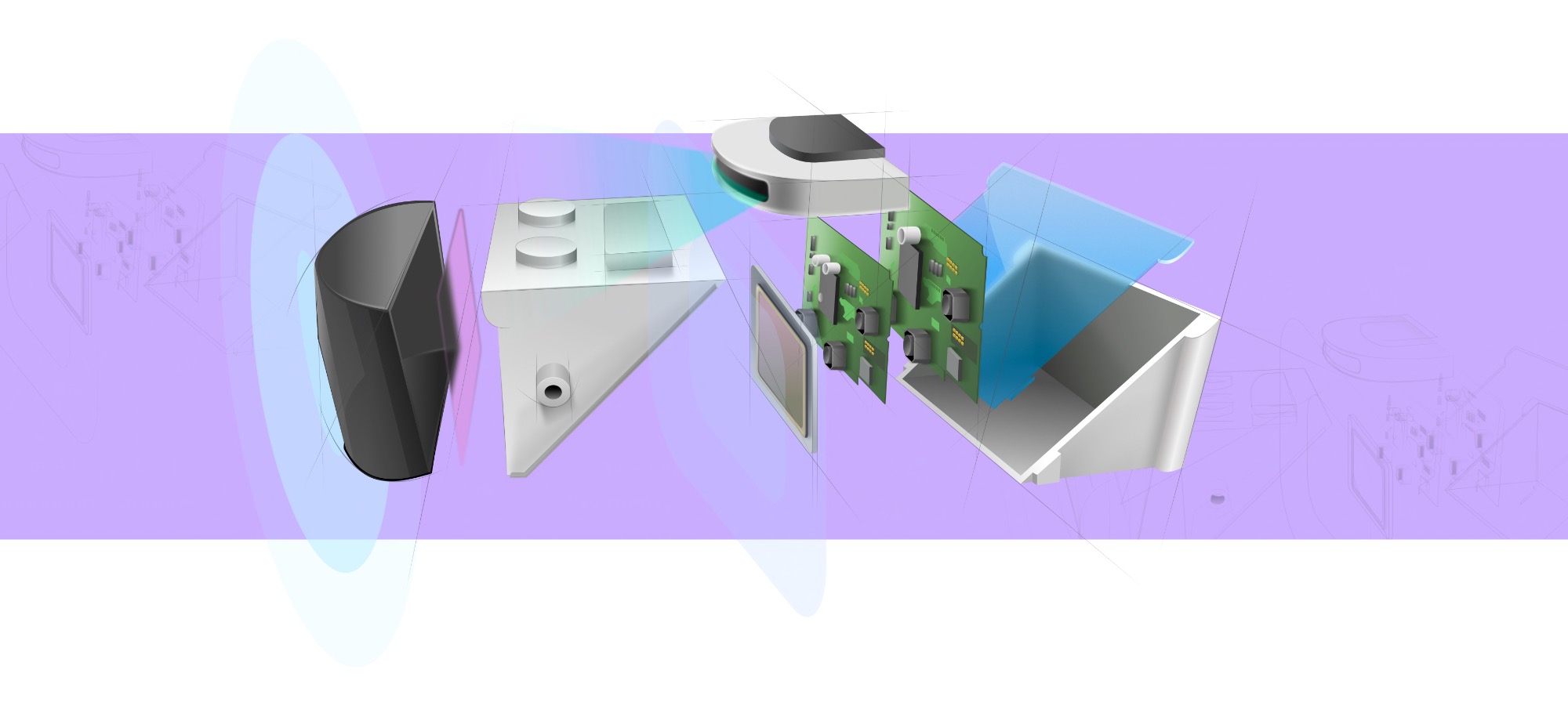

- At the heart of any ADAS car or autonomous vehicle, the data module combines information received from various sensors, processing a large amount of data. Responsible for processing image, radar and ultrasound data and displaying that data on the user interface.

- In addition, its ability to connect to the whole world will revolutionize the automotive industry, making our roads safer and our transportation more efficient. Therefore, the importance of the uncompromising functionality of this processing unit is critical to the ADAS system as a whole.

Conformal coating

A protective paint or conformal coating is a thin polymer film applied to a printed circuit board (PCB) in order to protect the board and its components from the environment and prevent corrosion.

Silicone sealant adhesives

One-component and two-component silicone sealant adhesives elastically absorb mechanical shocks due to dynamic stresses and compensate for thermal expansion between dissimilar substrates. They also manage to create resilient and tenacious joints under extreme temperature conditions.

Thermally conductive adhesives for electronics

Thermo-conductive adhesives have: excellent dielectric properties, excellent weathering resistance, stability over a wide temperature range, good adhesion on a wide variety of substrates, lower stresses on components, and resistance to ultraviolet rays and chemicals. The products can be used for applications in modules, connectors, sensors, PCBs and many more.

Continued on e-mobility

Advanced Driver Assistance Systems

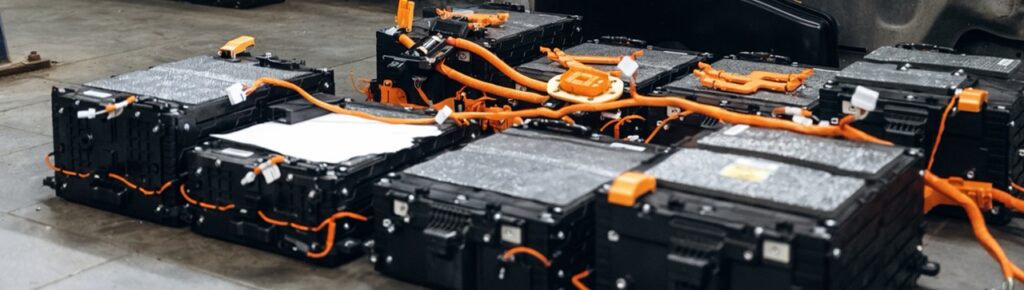

Read MoreBattery system

Read MoreElectric Drive systems

Read MorePower conversion system

Read MoreLatest articles on theAdvanced Driver Assistance Systems

Sign up for newsletter to receive upcoming articles

Thermal management: thermal management in electric vehicle batteries

Fire protection of electric vehicle batteries

MOLYKOTE® G-5133M Grease for automotive lubricants

New Electric Racing Motorcycle PoliMi Motorcycle Factory

EMAX ARTIC SYNT V: automotive lubricants for modern systems

Advanced thermal management for EV batteries

Reactive gas contact lubricants: the Krytox range

Read PDFs on theAdvanced Driver Assistance Systems