Industry

Aerospace and defense

Solutions for Aerospace and Defense: Reliable Materials for Extreme Missions

The aerospace and defense sector represents one of the most complex technological challenges of our time, where every component must ensure extreme performance, absolute safety, and reliability in critical environmental conditions.

Mascherpa products are designed to assist designers and engineers in protecting aeronautical, space, and military systems in a variety of extreme operating conditions, from installing components in corrosive environments to withstanding temperatures ranging from -115°C to +260°C, from exposure to the vacuum of space to intense mechanical stresses.

Mascherpa offers comprehensive solutions that go far beyond mere protection: our materials contribute to the functional and aesthetic design of systems, improving operational efficiency, reducing overall weight, and increasing the lifespan of critical components.

With a portfolio that includes adhesives, sealants, coatings, thermally conductive materials, specialty lubricants, and ablative materials, we meet diverse design needs, including compliance with MIL-SPEC standards, NASA regulations, and low outgassing requirements for space applications.

Aircraft, Helicopters, and Drones

Reliable Solutions for Manned Aircraft and Drones

Airplanes, helicopters, and UAVs (Unmanned Aerial Vehicles) require materials capable of ensuring environmental sealing, structural bonding, thermal management, and protection against electromagnetic interference (EMI). Both traditional and electric-powered aircraft require certified performance, particularly in critical electronic components.

Multi-purpose, solvent-resistant fluorosilicone sealants offer optimal performance in harsh environments. Silicone adhesives and foams are used for internal and external applications, as well as gaskets in compressors, reducers, and pumps. Other materials support the attachment of substrates to heat sinks in power transmission and conversion modules.

Electric aircraft also benefit from thermal solutions for battery management and related electronic systems. The range is completed by high-performance lubricating solutions for actuators, joints, and connectors, resistant to extreme thermal and environmental variations, designed to ensure operational continuity and reduce friction in prolonged cycles.

The safety and efficiency of airplanes, helicopters, and drones require versatile and durable materials capable of ensuring:

- Environmental sealing and resistance to fuels and hydraulic fluids

- Structural adhesives for metals and composites

- Thermal management for batteries and power modules

- Advanced lubrication for actuators, joints, and connectors

Mascherpa solutions enhance the reliability of aeronautical systems, supporting the development of the latest electric-powered aircraft.

Defense

Mission-Critical Performance for Extreme Environments

Military operations require robust solutions capable of withstanding critical conditions: desert heat, Arctic cold, tropical rains. Mascherpa materials offer reliability through a combination of mechanical properties and environmental resistance.

Coatings, gels, and encapsulants withstand shocks, mechanical stresses, and vibrations, also providing flame resistance. Many products are MIL-SPEC tested and UL certified. Lubricants ensure system functionality under dynamic load conditions, and fluorosilicone sealants maintain performance even in contact with fuels and oils.

High chemical and thermal stability lubricants are essential to ensure performance in harsh environments, improve the reliability of mechanical connections, and prevent corrosion and seizing even after long periods of inactivity.

For land, naval, and aerial military systems, we offer:

- Coatings and encapsulants for protection against shock, vibration, and moisture

- Solvent and fuel-resistant fluorosilicone sealants

- Anti-corrosion lubricants for critical components

- High-strength structural adhesives

All materials are available with MIL-SPEC certifications and meet robustness, longevity, and environmental resistance requirements.

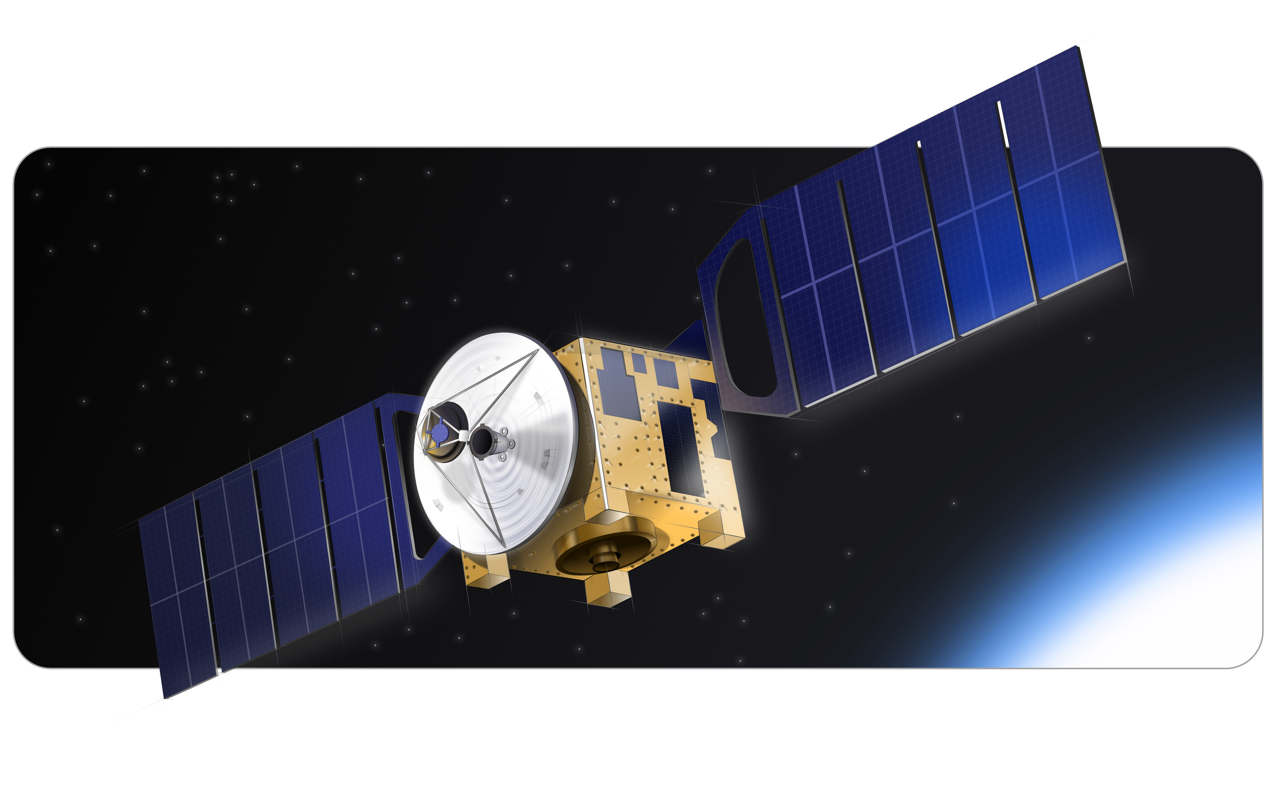

Space Shuttles and Satellites

Mission-Critical Systems for Space Vacuum

Materials used in spacecraft and satellites must ensure reliability in high vacuum conditions, where even minimal emissions can damage electronic, optical, and thermal systems.

Mascherpa sealants and encapsulants meet NASA’s low outgassing requirements (ASTM E595) and are available in thixotropic and fluid formulations. They offer physical and electrical stability over wide thermal excursions, protecting modules, relays, connectors, and optics from contamination and thermomechanical stress.

Ultra-low volatility lubricants, specifically formulated for use in vacuum environments, ensure reliability and high performance over the long term, preventing leaks, evaporation, or abrasion phenomena under microgravity.

In orbital and interplanetary contexts, we offer:

- Low volatility encapsulants compliant with ASTM E595

- Space-grade sealants for thermal vacuum environments

- Protection from radiation, thermal shocks, and atomic oxygen

- Lubricants for components subject to microgravity and exposure cycles

Each solution is designed to reduce outgassing, protect optical systems, and ensure operational continuity even in critical missions.

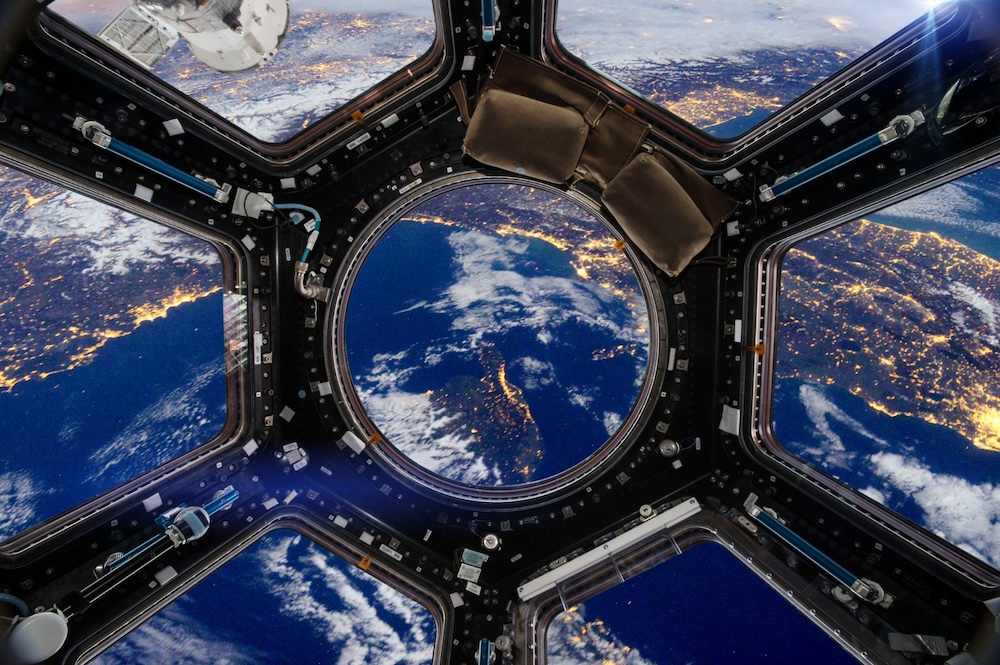

Avionics, Displays, and Lighting

Reliable Electronics, Sensors, and Lighting

To ensure safety and operability, pilots must rely on precise and durable avionics systems: displays, navigation lights, and sensors must operate without interference in all environmental conditions.

Mascherpa optically transparent materials resist humidity, extreme temperatures, and radiation, ensuring reliability even in miniaturized applications. Thermally conductive materials ensure effective heat dissipation in electronics, modules, and assemblies. Electrically conductive materials provide EMI shielding over a wide frequency spectrum.

High-performance lubricants help reduce vibrations and friction in the micro-mechanics of sensors and optical systems, ensuring operational stability even in the event of sudden thermal variations.

The visibility and safe operation of avionics systems depend on materials that ensure:

- Electronic protection from interference and discharges

- Compliance and flexibility with transparent silicone coatings

- Thermal management through gap fillers and thermally conductive adhesives

- Advanced optics with highly transparent moldable materials

- Precision lubrication for micro-electronic and optical components

Ideal for displays, wiring, sensor modules, navigation lights, and integrated optical systems.

New Frontiers

Materials for New Space Frontiers

The expansion of missions to the Moon, Mars, and beyond requires cutting-edge materials to protect launch infrastructures and next-generation modules. Mascherpa ablative materials defend launch platforms, nozzles, and heat shields from extreme thermal flows.

Our solutions include silicone coatings resistant to ablation, thermally conductive gels for electronics, and high green strength adhesives for substrates with different expansion coefficients. High-temperature lubricants support propulsion systems and structural components subject to intense thermal and mechanical stress.

With the increase in space missions and the development of hypersonic technologies, materials capable of withstanding extreme thermal flows are needed:

- Silicone ablative materials for launch platforms, heat shields, and nozzles

- Controlled decomposition coatings to protect against ablation

- High-performance encapsulants and adhesives for thermal expansion differences

- Stable high-temperature lubricants for propulsion structures and mechanical interfaces

Designed for multi-cycle applications and compatible with reusable infrastructures.

NEXT Partnership with Skyward Experimental Rocketry

From University Support to Space Conquest

Mascherpa collaborates with Skyward Experimental Rocketry, the team from Politecnico di Milano that designs and launches sounding rockets as part of the EUROC (European Rocketry Challenge). Within the NEXT partnership, we provide advanced technical materials for extreme aerospace applications: conformal coatings, vacuum lubricants, structural adhesives, and thermal management solutions.

This collaboration represents the meeting of engineering education, experimentation, and industry, and testifies to Mascherpa’s commitment to supporting future technologies from their development stages.

Latest industry articles Aerospace and defense

Sign up for newsletter to receive upcoming articles

Permabond TA 4550: acrylic adhesive for nylon

Silicone adhesive sealants for electronics and aerospace

Electrically Conductive Epoxy Paint and Adhesives: Various Applications

Two-component Silicone Adhesives for Rapid Bonding

Krytox™ Special Lubricants for the Aerospace Industry

Molykote Valve Grease: Cold Flow Test for Sounding Rockets

Silicones for Aerospace and Defense: the Frontiers of the Future