DOWSIL™ TC-5515 LT low-density thermally conductive gap-filler

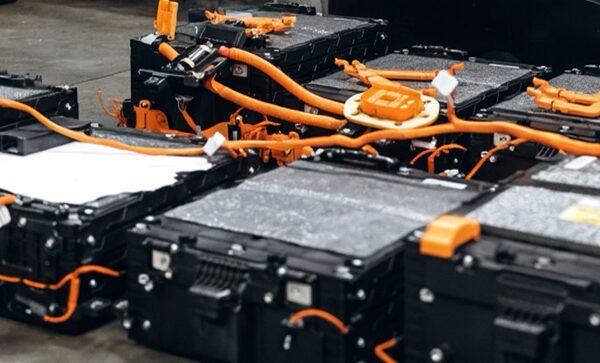

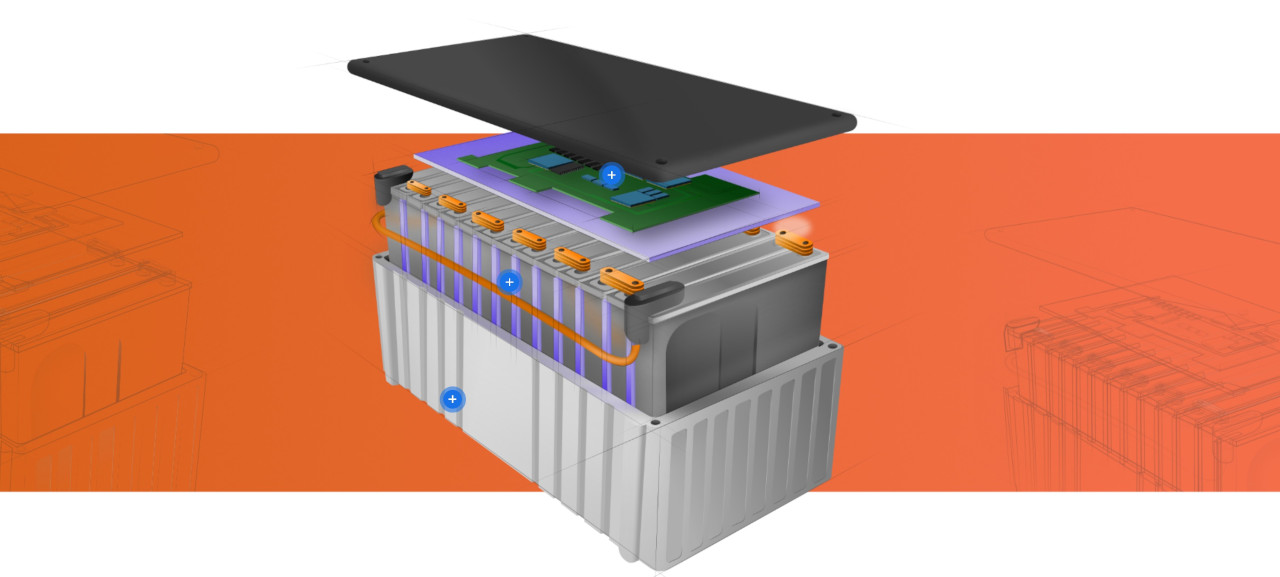

In the expanding electric vehicle (EV) market, battery packs are a key component. Thermal management is critical to the safety and durability of the EV battery pack. For EV battery heat dissipation, conductive gap filler is intended to become key thermal interface material.

To help meet the needs of this rapidly growing market, Dow has developed DOWSIL™ TC-5515 LT Low Density Thermal Conductive Gap Filler, featuring light weight (density 1.95 g/cm3), good thermal conductivity (2.0 W/m-K) and reliable performance for automotive applications.

DOWSIL™ TC-5515 is a two-component, low-density 2.0 W/m-K gap-filler that can be cured at room temperature. DOWSIL™ TC-5515 is a soft, compressible material once cured, specifically designed to dissipate heat from the EV battery and control unit modules.

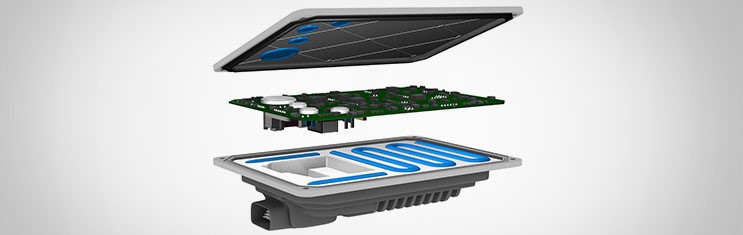

Dow engineers designed it to provide a reliable cooling solution for EV module manufacturers due to its unique properties is capable of dissipating heat from a heat source (typically EV modules, the printed circuit board) to a cold source (typically the aluminum housing that acts as a heat sink).

DOWSIL™ TC-5515 LT Low Density Thermally Conductive Gap Filler comes as a two-component liquid kit. When the liquid components are thoroughly mixed 1:1 by weight or volume, the mixture cures into a soft elastomer. Curing occurs without exothermic reaction at a constant rate regardless of section thickness or degree of confinement.

DOWSIL™ TC-5515 LT Low Density Thermally Conductive Gap Filler requires no post-cure and can be put into service immediately at operating temperatures from -45 to 150°C after completion of the curing program. Thermally conductive silicones function over a wide temperature and humidity range as heat transfer media with reliable, long-term protection of sensitive circuits and as shock and vibration absorbers, provide durable dielectric insulation, and are barriers against environmental contaminants.

USI:

EV battery group

Assembly of the electrical control unit module

BENEFITS:

- Heat dissipation

- Cost and weight reduction

- Simple application process and high productivity.

- UL 94 V0, low flame hazard.

- Reduced maintenance costs

- Sticky surface once cured, easy to rework after curing and assembly

- Low-density gap filler with reliable thermal conductivity and performance for lightweight EV battery assembly