Molykote BR2Plus in Industrial Furnace Guide Lubrication.

- Where lubricant is applied

- What is the problem

- Operating Parameters (LETS)

- Basic customer needs

- Molykote makes a difference

- The solution

In this article we will discover the main advantages of using Molykote BR-2 Plus in lubricating the telescopic guides of industrial ovens.

The benefits of Molykote BR2Plus in industrial furnace lubrication

Where is the lubricant applied?

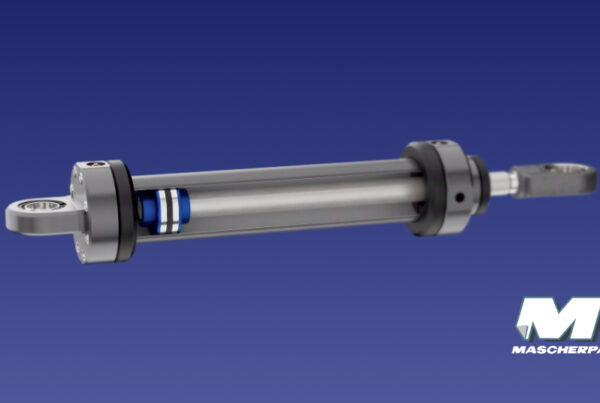

The telescopic oven rails

What was the problem?

- Component description: Telescopic oven guides.

- Previous solution: Grease with lithium thickener and with EP (extreme pressure) additives.

- Market segment: general industry.

- Application: telescopic guides of the oven opening.

- Main market: Maintenance, repair and overhaul (MRO).

- Product: Molykote BR-2 Plus Multi-Purpose Grease.

Operating Parameters (LETS)

- Load: High, shock load.

- Environment: Dusty exterior.

- Temperature: -40 to +130ºC.

- Speed: Up to 1.5 m/s.

- Process description: Centralized lubrication system (lubrication on a sliding surface).

Basic customer requirements

- Problem category: wear/breakage.

- Details of the problem: The grease oxidized rapidly by constantly heating to +130ºC and being exposed to dust, there was wear in the contact plate.

- Root cause analysis: The previously used grease (with EP additives) could not withstand the high temperatures and abrasive dust fragments, and as a result furnace failure occurred.

Molykote makes a difference

The product offered good adhesion, protection against wear and corrosion, and long-term stability. Molykote BR-2 Plus resists wear due to constant heating and is adequate for long-term lubrication. Solid lubricants form a fine film in the contact surfaces, thereby reducing wear and tear.

The solution

By using a grease with solid lubricants, the service life of the furnace sealant assembly are increased from 6 to 24 months, reducing maintenance costs, downtime and equipment.