Key Points

- I fats with al calcium sulfonate from the range Condat Millenium offer thermal stability, resistance to shocks e corrosion protection even in environments salines thanks to the colloidal structure which allows high performance Without high percentages of additives.

- The range is designed for heavy-duty applications in heavy industry such as bearings and pellets, rolling machines, open gears, guides and cables with advantages in multi-service stock management as well.

- Characteristics include viscosities from ISO 46 to ISO 1500, grades NLGI 0 to 3, options biodegradable according to OECD 301, high drip point, excellent behavior in the presence of water and corrosion protection.

- Operational benefits include reduction in grease consumption, lower maintenance costs, longer lubrication intervals longer and increased reliability of the systems with continuity of operation even under extreme conditions typical of steelmaking.

- Experimental evidence shows stable lubricant texture at 150 °C for 22 hours, high load resistance in the 4-ball test, ability to absorb water up to 40 percent while maintaining a continuous film, and mechanical stability in the Shell Roller Test with sealing power.

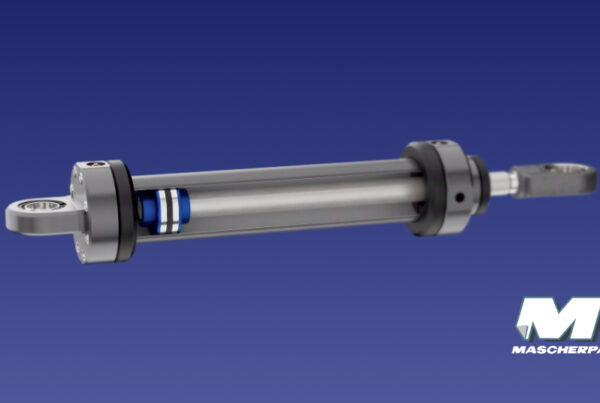

Technology calcium sulfonate, also sometimes called calcium sulfonate, employed in fats Condat Millenium was created for the lubrication of mechanical systems subjected to heavy loads and/or water runoff, where they serve stability, impact resistance e corrosion protection even in saline environments. The colloidal structure typical of calcium sulfonate enables high performance without high percentages of additives, offering lubrication that is efficient, multipurpose and long-lasting.

This technology is adopted across the board inheavy industry where exposure to water, shocks e high pressures is the norm.

Condat Millenium grease applications

The range of fats Condat with a complex soap of calcium sulfonate, has very high drop points that allow them to meet stringent load and temperature constraints while maintaining their effectiveness even in wet environments. These properties make them optimal for the following applications:

- bearings (roller, rolling; including those on crushing screens and pellet presses),

- rolling machines (in the steel industry),

- open gears,

- guides,

- cables.

The versatility of the range Condat Millenium allows for uses high-end multi-service, also useful for optimizing the stock of lubricating greases in the plant.

Characteristics of fats with calcium sulfonate

- Wide selection of base oils: mineral, semi-synthetic, 100% synthetic.

- Viscosity range.: ISO 46 to ISO 1500.

- NLGI grades.: 0 to 3.

- Biodegradable options according to OECD 301.

- Excellent behavior in the presence of water.

- Natural resistance to shocks and heavy loads.

- Very high drip point.

- Corrosion protection even in saline environments.

Advantages of Condat Millenium sulfonate lubricants

- Wide temperature range-40 to 200 °C.

- Mechanical stability under severe rolling conditions (maintained grip resulting in reduced wear).

- Resistance to shock and vibration (help prevent breakage while reducing maintenance costs).

- Protection in the presence of water (contribute to longer life of mechanical parts).

- High-end multipurpose: suitable for extreme conditions typical ofheavy industry.

Tests passed by products with calcium sulfonate

The following is a summary of the technical tests used to evaluate the technology calcium sulfonate in fats Condat Millenium, with comparative reference to the lithium grease traditional as a comparison sample:

- Oil evaporation test,

- 4-ball test (ASTM D2596),

- Test water absorption capacity,

- Shell Roller Test (ASTM D1831).

Oil evaporation test

Under extreme thermal conditions (150 °C for 22 hours on 1000 mg layer), Condat Millenium maintains a “buttery” texture and the lubricating capacity at the end of the trial. This behavior is consistent with the high temperature stability of the chemistry at calcium sulfonate.

Benefits highlighted

- Lubrication tightness at the end of the test.

- Contribution to lower consumption (-40%), reduced maintenance costs (-25%), longer lubrication intervals e increased productivity.

4-Ball Test (ASTM D2596)

At the pressure of 400 kg for 10 s, Condat Millenium completes the test without fumes and with unpaired balls (no welding and seizing), confirming high resistance to loads and pressures typical of the steelmaking.

Benefits highlighted

- Resistance to shock loads and high pressures.

- Supporting the continuity of operation (fewer seizure events resulting in improved reliability of the asset).

- Alignment with operational benefits already seen: reduced fuel consumption, low maintenance, longer intervals.

Water absorption capacity test

Thanks to the micellar structure (core of calcite + base oil), fats Condat Millenium absorb up to 40% water keeping lubricating properties e continuous and stable film on the bearing; the consistency remains controlled even with high percentages of water.

Benefits highlighted

- Continuous lubricating film in the presence of water.

- Stable properties: support for the durability of components in humid environments.

- Impact on reduced consumption (-40%) and maintenance costs (-25%).

Shell Roller Test (ASTM D1831)

With sample preparation 135 g fat + 15 g water (10%) and cycle 24 h / 66 °C / 10 rpm / 10% water, the penetration measurements at 25 °C show for Condat Millenium: a consistency maintained. The sealing power remains effective and the properties of the grease are confirmed after mechanical stress with water.

Benefits highlighted

- Stability of consistency e sealing tightness after prolonged processing in the presence of water.

- Contribution to operating reliability, longer intervals and lower overall fat consumption.