Key Points

- Battery energy storage systems (BESS) are essential for integrating intermittent renewable sources such as solar and wind energy.

- The technical challenges of BESS involve structural reliability, environmental protection, and thermal management over the long term.

- DuPont’s advanced adhesive solutions overcome the limitations of traditional mechanical fastenings.

- Structural, thermally conductive adhesives and sealants contribute to the safety, durability, and efficiency of storage systems.

- Choosing the right adhesive is a key design factor for consistent performance and optimized maintenance of BESS.

The global energy landscape is transforming, with outdated power grids struggling to meet growing demand and integrate renewable energy sources.

At the heart of this revolution is a crucial challenge: how to store and distribute energy effectively from intermittent renewable sources like wind and solar energy.. I Battery energy storage systems (BESS) have emerged as the key technology to address this challenge, and innovative adhesive solutions are proving essential to their success.

The growing need for energy storage systems

Transmission and distribution networks of electricity worldwide are under increasing pressure due to aging traditional infrastructures and the accelerated adoption of renewable energies.

The limitations of intermittent renewable sources

The intermittent nature of renewable sources presents unique challenges:

- Wind farms cannot generate electricity when the air is calm;

- Solar panels are ineffective during cloudy weather;

- Hydroelectric systems depend on water flow.

This variability creates an urgent need for energy storage solutions capable of capturing excess renewable energy during peak generation periods and releasing it when demand is high or renewable sources are unavailable.

The strategic role of BESS systems

Energy storage systems with stationary batteries offer compelling advantages for modern energy infrastructures. They provide rapid response capabilities to ensure a constant energy supply during periods of high demand or emergencies. Perhaps even more significant is that BESS technology can eliminate the need for costly peaker plants, which are fossil-fuel-powered plants that operate only during periods of extremely high electricity demand and typically charge premium rates per kilowatt-hour.

BESS units serve as backup power supplies for community facilities and industrial operations where continuous power

is absolutely critical. They also provide on-demand energy for residential applications, supporting the growing trend towards distributed energy systems and energy independence. is absolutely critical. They also provide on-demand energy for residential applications, supporting the growing trend towards distributed energy systems and energy independence.

Technical challenges in BESS development

Despite the advantages of battery energy storage systems technology, significant engineering challenges remain. The transition from electric vehicle battery technology to large-scale stationary storage applications requires substantial modifications and optimizations. electric vehicle batteries to large-scale stationary storage applications requires substantial modifications and optimizations.

Architecture and configuration of battery energy storage systems

Stationary BESS installations typically comprise stacked battery packs of various sizes and configurations, connected to form assemblies capable of storing and releasing megawatts of power.

These assemblies must be housed within structures designed to withstand extreme environmental conditions while ensuring accessibility for maintenance and service on a regular basis. I Housing systems require sophisticated designs for roofs, floors, and side walls to protect the sensitive components of the batteries from moisture, temperature fluctuations, and physical damage over a lifespan exceeding 20 years.

Reliability and protection requirements for battery energy storage systems

Battery energy storage systems must:

- maintain structural integrity during transport and installation;

- resist water ingress that could cause component failures;

- provide reliable sealing against environmental contaminants.

Traditional mechanical fastening methods often prove inadequate for these demanding applications, creating opportunities for advanced adhesive technologies.

Revolutionary adhesive solutions for battery energy storage systems

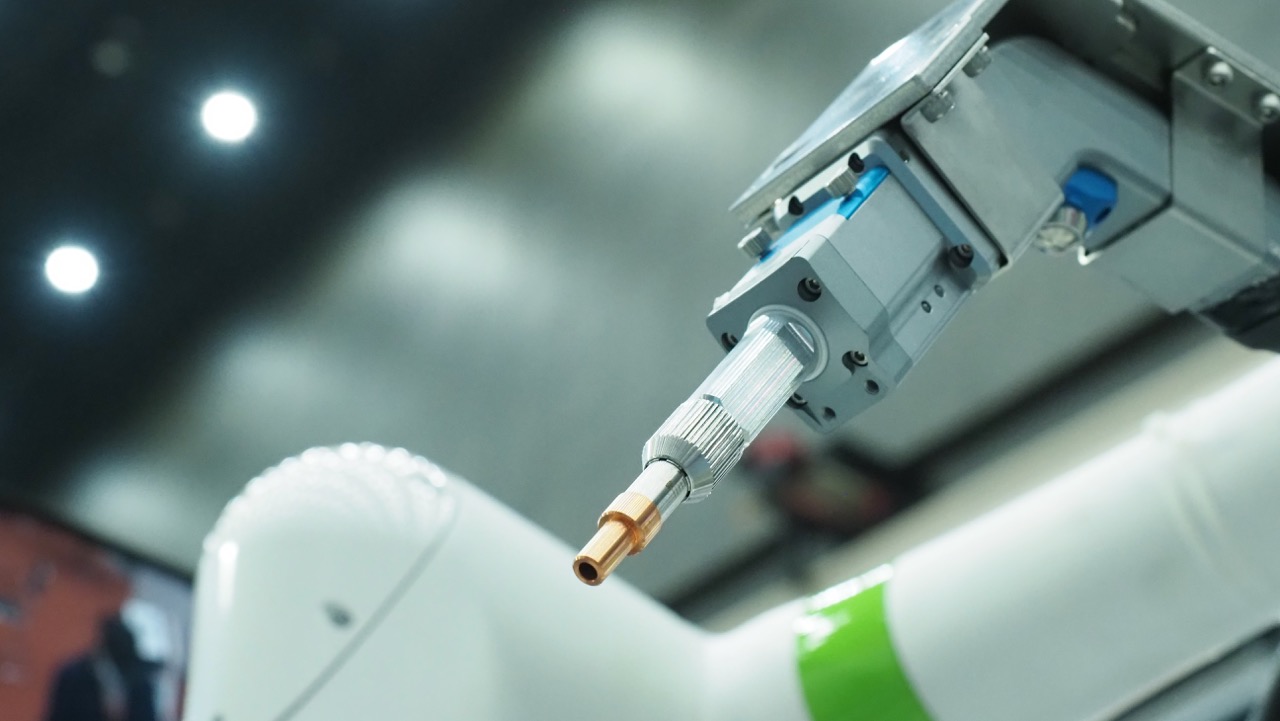

DuPont’s advanced adhesive technologies are transforming BESS manufacturing and assembly processes, leveraging decades of experience in transportation markets to provide specialized solutions for energy storage applications.

The full range of BETAMATE™, BETAFORCE™, and BETASEAL™ products from Mascherpa offers numerous fundamental advantages.

BETAMATE™ adhesives for battery energy storage systems

BETAMATE™ adhesives are used for roof and floor bonding applications and ensure reliability in critical structural applications.

The main advantages of products BETAMATE™ for roof and floor bonding include the replacement or the reduction of welds, where the continuous adhesive bond creates watertight seals capable of withstanding extreme conditions preventing for water ingress thedamage. and the resulting possibility of corrosion.

The strength and flexibility characteristics of BETAMATE™ adhesives allow for bonds robust enough to last the entire service life of BESS installations.

These adhesives offer exceptional structural strength while maintaining precision and flexibility necessary to accommodate bending and curvatures during transport and installation procedures of storage units. These balanced performances ensure system integrity from manufacturing to decades of operational service.

Resistance to extreme environmental conditions represents another key advantage. In addition to Moisture resistance and water ingress, BETAMATE™ adhesives withstand extreme temperature and humidity fluctuations without degrading.

Additionally, these solutions maintain compatibility with powder coatings, offering clean class A finishes and a professional appearance, essential for installations in populated areas.

Thermally conductive adhesives BETAMATE™ and BETAFORCE™

Thermally conductive adhesives BETAMATE™ and BETAFORCE™ represent innovative solutions for battery pack assembly.

These innovative products provide durable structural bonding while also offering effective thermal management capabilities. Facilitating efficient heat transfer from battery cells to cooling systems, these adhesives significantly enhance safety and enable part consolidation in critical applications, including:

- cell-to-cell connections;

- cell-to-plate assemblies;

- cell-to-cooling tape bonding.

This dual functionality eliminates the need for separate components for thermal management while maintaining structural integrity.

Structural adhesives BETAMATE™ and BETAFORCE™

The ranges of structural adhesives BETAMATE™ and BETAFORCE™ enhance the strength and overall longevity of the system thanks to their exceptional bonding capabilities.

These products optimize production costs by significantly reducing reliance on mechanical fasteners and welds, simplifying assembly processes while supporting complex multimaterial bonding applications.

BETASEAL™ sealants

BETASEAL™ sealants provide essential functionality for maintenance and service operations. These specialized products facilitateaccess to individual cells and battery modules during repair or replacement procedures, maintaining system integrity and environmental protection. This capability significantly reduces maintenance costs and downtime for battery energy storage systems.

Comprehensive solutions for battery energy storage systems

In battery energy storage systems, adhesive solutions play an increasingly strategic role, contributing to safety, reliability, and durability of installations over the long term. From structural bonding to thermal management, to sealing and maintenance, advanced adhesives enable more efficient and integrated design approaches to tackle BESS technical challenges.

To explore the most suitable solutions for different battery energy storage systems and assess the best approach based on the application, contact the Mascherpa experts, who will assist you in selecting the most appropriate adhesive technologies.