Electrolube Launches New Generation of UV Cure Conformal Coating

The UVCL range is solvent-free, free of volatile organic compounds and offers unsurpassed performance in harsh environments, including resistance to cracking during thermal shock cycles. The main advantage of Electrolube’s UV Cure coatings is that the boards can be handled immediately, with full cure guaranteed within 6-12 hours due to the secondary cure mechanism. Compared to existing UV curing systems on the market, most require minimum secondary curing times of 8-14 + days, while the new UVCL range allows huge reductions in the labor hours required

UVCL UV CURE CONFORMAL COATING

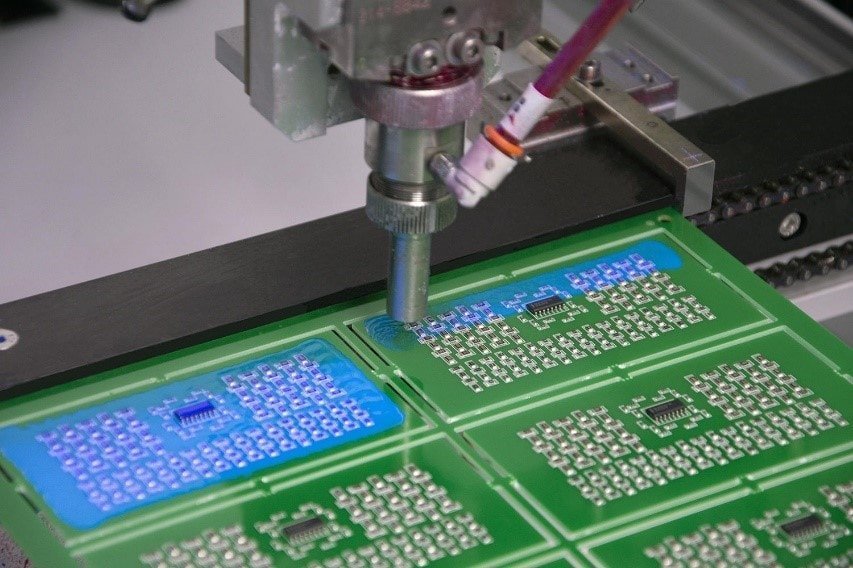

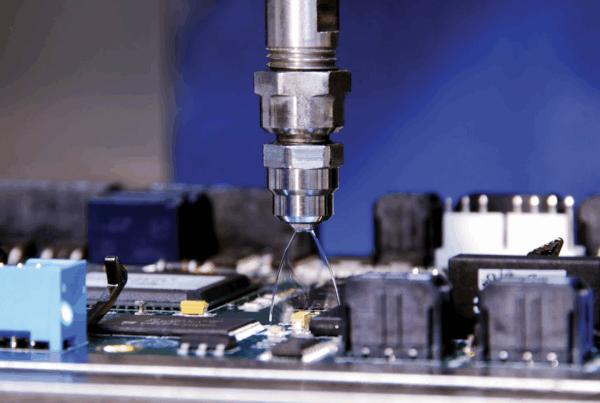

UVCL is a single-component, low-viscosity coating that cures in seconds with exposure to the correct dose of UV light with secondary moisture curing for complete cure in shaded areas. Available in 5-liter packages, UVCL is VOC-free, nonflammable and demonstrates excellent electrical properties. The coating offers a wide operating temperature range and is ready for use for application with automatic selective machine

UVCLP UV CURE CONFORMAL COATING

UVCLP is part of the new generation of conformal coatings for UV curing developed by Electrolube to offer the highest levels of protection while maintaining a fast processing time. Applied with a selective coating machine, UVCLP offers an outstanding processing time compared to other UV curing coatings. UVCLP is dry to the touch after brief exposure to the correct wavelength of UV light, with complete cure guaranteed in less than 24 hours due to the secondary chemical curing mechanism. Chemical curing ensures that even shaded areas are fully cured within a few hours. This is in sharp contrast to other traditional UV coatings that can take weeks to fully cure; (some shaded areas will also remain uncured). UVCLP thus guarantees reduced working time.

UVCLP is optimally applied between 100-150 μm and provides excellent edge coverage, even on sharp components, ensuring the highest levels of protection even during temperature cycling and thermal shock.

To add to this UVCLP offers outstanding performance in harsh environments, its hydrophobic nature imparts excellent protection from moisture, salt spray, and even full immersion for short periods with the ability to extend this period by applying the coating in a thicker layer. UVCLP is also flame retardant that meets the criteria for UL94 V-0 when applied below 150 μm.

UVCLX UV CURE CONFORMAL COATING XTRA

UVCLX is part of the new generation of UV Cure conformal coatings developed by Electrolube to offer the highest levels of protection while maintaining a fast processing time. Applied via a selective coating machine, UVCLX is based on the speed of a conventional UV coating, being dry to the touch after brief exposure to the correct wavelength of UV light. A complete cure is guaranteed in less than 24 hours by virtue of the secondary chemical curing mechanism. Chemical curing ensures that even shaded areas are fully cured within a few hours. This is in sharp contrast to other traditional UV coatings that can take weeks to fully cure; (some shaded areas will also remain uncured). Therefore, UVCLX guarantees reduced working time.

UVCLX is optimally applied between 150-250 μm and achieves excellent edge coverage, even on sharp components. This ensures that UVCLX achieves the highest levels of protection, even during temperature cycling and thermal shock. UVCLX offers outstanding performance in harsh environments; its hydrophobic nature gives it excellent protection from moisture, salt spray, and even total immersion for short periods, and it can be applied more often as required for such applications.