Key points of the article

- Electric vehicle battery safety is a top priority: innovative, heat-resistant materials help prevent thermal propagation and protect passengers and performance.

- Silicone solutions for thermal and environmental protection ensure reliability even under extreme conditions, offering fire resistance, electrical insulation and mechanical stability.

- LSR coatings and encapsulants, foams, and rubbers represent a full range of materials designed to mitigate the effects of heat, shock, and vibration while preserving battery integrity.

- Dow’s formulations dedicated to the e-mobility sector ensure effective barriers against flames and high temperatures, improving the safety of storage modules and the durability of the system.

- Silicone adhesives and foams offer fast and safe assemblies, thanks to controlled curing processes and the ability to maintain flexibility and elasticity over time.

- Lightweight low-density foams, such as DOWSIL™ EF-6555 Silicone Foam, contribute to passive fire protection and thermal insulation, improving overall battery efficiency and safety.

As electric vehicles evolve, safety remains a top priority.

Dow, a Mascherpa partner, is leading the way with advanced electric vehicle battery fire protection (BFP) materials designed to help prevent thermal propagation events, protecting both passengers and performance.

Innovative solutions for an electric vehicle battery protection

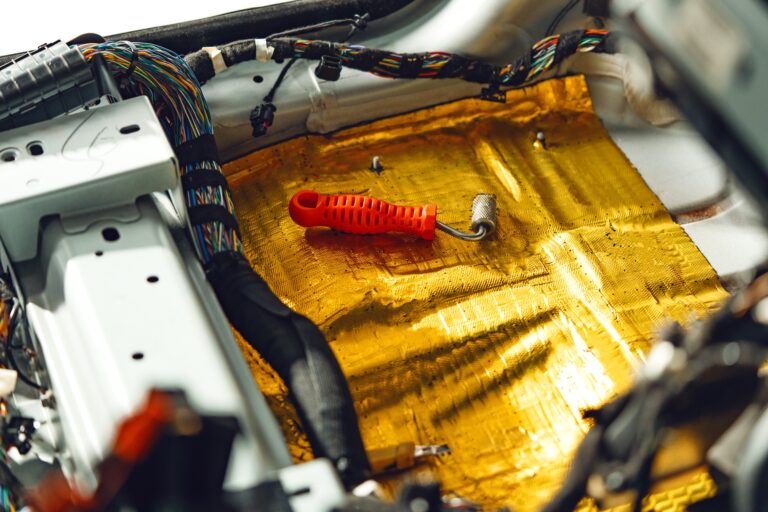

Solutions for thermal and environmental protection of electric vehicle batteries include several technologies designed to ensure safety and reliable performance even under extreme conditions.

Depending on application needs, there is a choice of coatings and encapsulants, silicone foams or high consistency rubbers, each with specific characteristics in terms of heat resistance, electrical insulation and fire behavior.

LSR coatings and encapsulants

LSR coatings and encapsulants with room-temperature curing and ceramization in thermal events or high temperatures provide effective protection from heat, flame and particle explosions.

Silicone foam

Fast-curing, low-density silicone foam offers vibration-reducing properties , electrical isolation , and determinic and flame-retardant protection through ceramization.

High consistency tires

High consistency rubbersoffer fast curing, superior electrical insulation, and thermal and flame protection through ceramization.

Dowsil™ products for fire protection of electric vehicle batteries

Dowsil™ silicone solutions are an advanced answer to the fire protection and thermal insulation needs ofelectric vehicle batteries .

With their excellent properties of heat resistance, stability over time, and ability to create protective barriers, these materials help improve the safety, reliability, and durability of energy storage systems in electric cars and motorcycles.

The main products used in this area include:

- DOWSIL™ EA-3838 Fast Adhesive

- DOWSIL™ 3-8259 RF Silicone Foam Kit

- DOWSIL™ EF-6555 Silicone Foam

DOWSIL™ EA-3838 Fast Adhesive

DOWSIL™ EA-3838 Fast Adhesive is a room temperature fast-curing silicone adhesive designed for the assembly of automotive electronic components, with excellent weathering resistance and thermal stability.

Due to its reliability and consistent mechanical properties over time, it also finds application in the fabrication and sealing of electrical battery modules, where it is critical to ensure durable adhesion and protection from thermal and environmental stresses .

This adhesive is distinguished by its rapid and homogeneous deep curing, which enables fast handling of bonded components and an optimized assembly process.

The pasty, non-self-levelling consistency ensures precision application even on vertical surfaces, whileearly adhesion at room temperature reduces processing time.

Key features include:

- Durable adhesion to a wide variety of substrates, including metals, plastics , and composite materials.

- High resistance to weathering and UV rays.

- Fast assembly process suitable for automated production lines.

- Elastomeric properties.

DOWSIL™ EA-3838 Fast Adhesive thus represents a versatile, high-performance solution for applications where safety, strength, and rapid processing are essential requirements, such as in electronic systems and battery structures for next-generation electric vehicles.

DOWSIL™ 3-8259 RF Silicone Foam Kit

DOWSIL™ 3-8259 RF Silicone Foam Kit is a two-component room temperature silicone foam system designed to be dispensed and cured directly onto components to form an integrated compression seal.

This solution ensures precise and uniform application, ideal for protecting modules and enclosures subject to thermal or environmental changes.

Its formulation features medium hardness (Shore 00) and low flow, which facilitates its application even on sloping surfaces.

It is easy to use, thanks to the 1:1 mixing ratio, and allows rapid curing at room temperature, eliminating the need for temporary storage of tooled parts.

Key features include:

- Low compression set, maintained even at high service temperatures.

- Stability and flexibility over a wide range of operating temperatures.

- Efficient and controlled application, suitable for automated processes.

- Elastomeric properties.

Because of these properties, DOWSIL™ 3-8259 RF Silicone Foam Kit is a reliable solution for sealing and thermal protection in applications where elastic and durable seals are required, such as in thermal management systems and protection of electronic modules.

DOWSIL™ EF-6555 Silicone Foam

DOWSIL™ EF-6555 Silicone Foam is a low-density silicone foam designed for the production of foam sheets intended for fire protection and thermal insulation of electric vehicle batteries.

Due to its lightweight and homogeneous structure, it offers an excellent combination of heat resistance, dimensional stability and insulation capacity, making it particularly suitable for applications where safety and thermal management are key priorities.

Innovation in battery protection for electric vehicles

Fire protection of electric vehicle batteries requires technical expertise, next-generation materials, and an integrated approach to safety.

Mascherpa experts support companies and designers in choosing the most effective silicone solutions to improve thermal insulation, durability, and reliability of energy storage systems.

Collaboration with university entities such as the PoliMi Motorcycle Factory, part of the NEXT project, reflects Mascherpa ‘s ongoing commitment to promoting innovation and technology transfer in the field of electric mobility.

Contact Mascherpa experts to find out the best solutions dedicated to thermal and fire protection of electric vehicle batteries. Or download our technical guide on thermal management.