I

Conformal Coating ELECTROLUBE

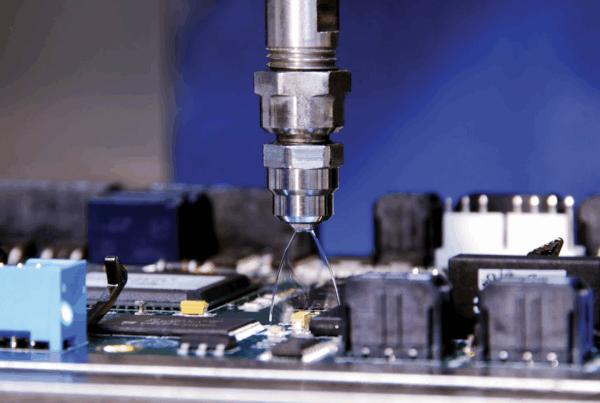

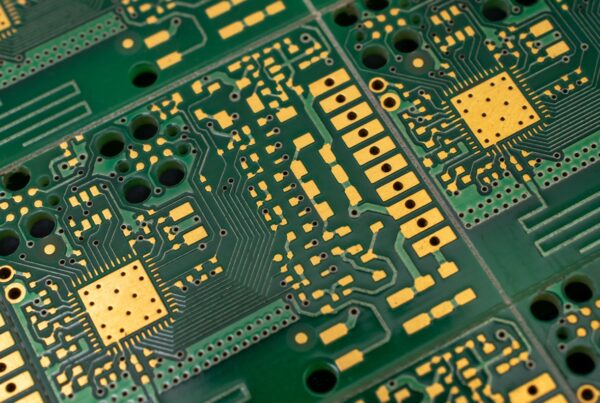

are thin polymer films that cover and protect solder joints, electronic component leads, exposed traces and other metallized areas on PCBs, from corrosion in end-use operating environments. Moisture, condensation, salt spray, corrosive gases, or a combination of all of these, activate the start of the corrosion process, which can be accelerated by welding residues and other processes prior to coating.

With the increasing adoption of electronics in developing countries, where air pollution levels are generally higher, the need for corrosion protection increases. In addition, there is a growing trend toward smaller devices with greater functionality, resulting in higher density assemblies that are expected to operate smoothly for extended life in increasingly aggressive operating environments.

I

conformal coatings

Electrolube can have different chemical nature, and may more or less suit your needs, in this table you will find summarized the main characteristics,

ask the expert

which conformal coating is perfect for you

|

Coating |

Benefits |

Disadvantages |

|

Acrylic |

Simple to use |

Low resistance to solvents |

|

Urethane |

Simple to use |

High VOC emissions Difficult to rework |

|

Silicone |

Excellent performance at high and low temperatures Perfect water protection Low odor,easy to use |

Little protection against corrosive gases May have VOC emissions |

|

UV crosslinking |

Low VOC emissions Fast curing |

Very sophisticated process Difficult to rework |

Remember that the

Conformal coating

can only protect the surfaces where it is applied with perfect coverage, and that voids, bubbles, and cracks in the coating will likely initiate the corrosion process.

Choose the chemistry of the

Conformal coating

that suits your needs and can withstand the expected environmental challenges is critical.