Molykote anti-friction coatings, for dry lubrication

Anti-friction coatings (AFC, also known as Anti-friction coatings) are like paints that instead of a dye pigment contain particles of a few microns in size of solid lubricants dispersed through a mixture of carefully selected resins and solvents.

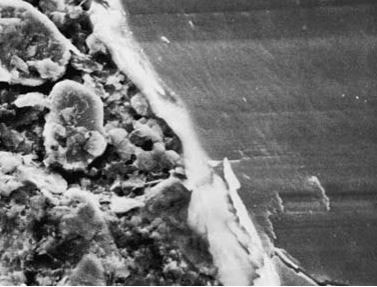

SEM 1000x image. comparative of a substrate without (left) and with (right) the application of an AFC. The change in roughness and homogenization of the surface is observed

The correct choice of raw materials and the volume of concentration of the contained lubricant are critical for proper lubrication and corrosion protection properties. When applied, they form a dry slippery film that reduces the coefficient of friction as it homogenizes surface roughness and thus optimizes metal-to-metal, metal-to-plastic or plastic-to-plastic friction, even under extreme loads and working conditions.

Solid lubricants adhere to the surface due to the cohesive force of the resin, and in this way, surfaces are always separated by an effective dry lubricating film, which is very durable even under conditions of very low speeds, oscillating movements, high loads and aggressive environments.

Advantages of anti-friction coatings (AFC)

- Clean and dry lubrication.

- Minimize friction and wear through long-life lubrication.

- They provide very low coefficients of friction with very little variability.

- They can be used under extreme conditions, such as very high temperatures, high loads and vacuum conditions.

- Especially effective in dusty environments or working environments with suspended particles.

- They create a protective physical barrier that is resistant to mechanisms that promote corrosive processes.

- In many of them, they dry at room temperature and within minutes.

- In other cases, hot curing provides stronger anchorage and better corrosion resistance.

- The thermal resistance ranges, depending on the type, from -200°C to +650°C.

- They strengthen lubrication with oil or grease and with it better functioning of mechanical components.

- There are specific anti-friction coatings (AFC) for all types of materials, such as metals, plastics, elastomers, leathers and wood.

- Its application is clean, friction points and working environment do not get dirty.

- Some of them are transparent.

- Avoid vibration wear and tear (contact corrosion).

- With proper application, thin lubricant layers (between 5 and 30 μm) are guaranteed.

- They hardly change the geometry of the substrates to which they are applied.

- Its average surface coverage capacity is about 15 m2/kg

- They can be reapplied to the same coating, recovering their properties.

- There is no fragility of hydrogen.

- Improves the possibilities of assembling mechanical elements

- Minimizes maintenance

- Extend relubrication periods.

- Minimizing economic costs.