Key points of the article

- A large mining facility South American was experiencing irregular wear and seizures in the trunnions of its SAG mill, causing machine downtime and high maintenance costs.

- The challenge was to find a lubricating paste capable of operating under extremely high loads, reducing friction and extending the service life of the mechanical components.

- Molykote P-74 was therefore selected, a high-performance paste based on MoS₂, effective against wear, seizure and metal-to-metal contact.

- The application led to immediate improvement: longer service life of the couplings, stable lubrication and reduction of maintenance interventions.

- This case demonstrates the importance of relying on tested technical lubricants to ensure efficiency, operational continuity and protection even under extreme conditions.

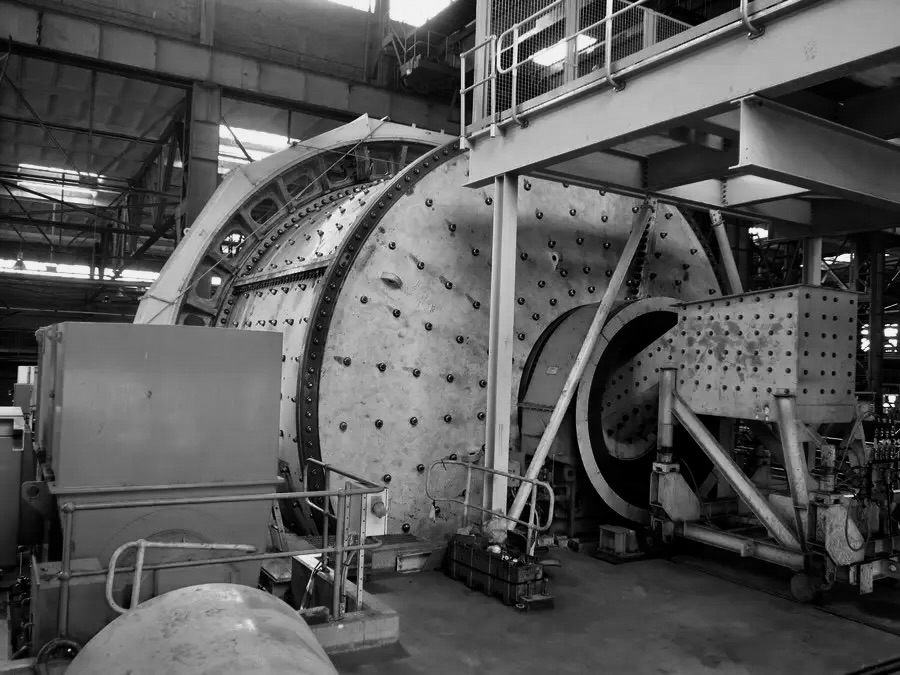

In the extractive sector, operational continuity is a critical factor. Grinding plants, such as SAG mills (Semi-Autogenous Grinding), operate under extreme load conditions, temperature and vibration.

Inadequate lubrication of the trunnions can lead to unplanned machine downtime, premature wear and high maintenance costs.

For this reason, the choice of trunnion lubricant cannot be left to chance. In this blog we analyze a real case study that demonstrates how Molykote P-74 has provided an effective and lasting solution for the lubrication of SAG mill trunnions.

Early Wear and Excessive Friction in Mill Trunnions

A major mining facility in South America was facing recurring maintenance problems due to irregular wear and seizures in the trunnions of its SAG mill.

The lubricant in use could not guarantee sufficient protection under extreme loads, generating frequent maintenance interventions, unplanned downtime and progressive deterioration of the mating surfaces.

The technical challenge consisted in finding a lubricating paste capable of:

- Operating under conditions of high pressure and dynamic load;

- Reducing startup friction;

- Preventing metal-to-metal contact;

- Increasing maintenance intervals.

Molykote P-74 for high-performance lubrication

To meet these requirements, Molykote P-74 was adopted, a high-performance assembly paste formulated for high-load applications and low speeds.

Its composition based on solid lubricants, particularly molybdenum disulfide (MoS₂), ensures a very low friction coefficient and lasting protection against wear.

Key characteristics of Molykote P-74

- Excellent anti-seizure capability: prevents direct contact between surfaces even under extremely high loads.

- High thermal stability: withstands up to 400°C, making it suitable for high-temperature environments.

- Long-term protection: reduces relubrication intervals and extends the service life of components.

- Versatile application: can be used on trunnions, bushings, guides, bolts and mechanical couplings in general.

In the specific case, the application involved cleaning the surfaces and applying a thin and uniform layer of Molykote P-74 during the trunnion assembly phase.

Efficiency and Reduction of Maintenance Costs

The use of Molykote P-74 led to immediate and tangible results:

- Reduction of initial friction at mill startup

- Elimination of seizure in the trunnions

- Increased service life of couplings

- Extension of scheduled maintenance intervals

According to the plant technicians, the performance of Molykote P-74 paste has exceeded expectations, enabling more reliable and stable lubrication, even under critical operating conditions.

Rely on Tested Solutions for Lubrication

-

The choice of a technical lubricant can make the difference between an efficient plant and one subject to continuous machine downtime.

The case study on SAG mill trunnion lubrication demonstrates the effectiveness of Molykote P-74 in reducing friction, wear and maintenance in a context of extremely high mechanical stress.

For those operating in the mining sector or heavy industry, it is essential to rely on tested and high-performance solutions.

Mascherpa experts are available to provide technical consulting and support in selecting the lubricants most suitable for specific application requirements.

Contact us to receive consultation on Molykote P-74 or other high-performance lubrication solutions.