The Anti-Friction Coating

Molykote

D-709, formulated with Polytetrafluoroethylene (PTFE), provides a low coefficient of friction on metal parts to reduce noise and wear between metal-on-metal and metal-on-plastic surfaces.

This dry coating remains effective when exposed to contaminants such as dust and dirt, resists moisture and is not subject to water runoff, maintains lasting lubrication without aging, evaporation or oxidation; can help ‘lighten the car for greater efficiency, and avoid the use of “oily” lubricants.

The new

Molykote

D-709 in silver color offers the same high performance and benefits as the glossy black dry lubricant

Molykote

D-708, which has proven effective in classic applications

in the automotive industry

such as springs and brake pad pins.

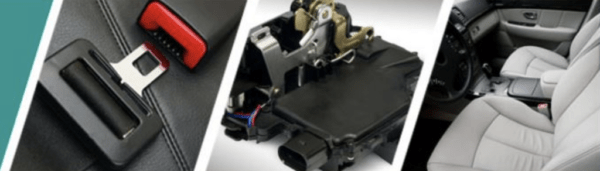

With an eye-catching silver metallic finish, the anti-friction coating Molykote D-709 can achieve aesthetically pleasing results for the lubrication of all those more visible design components, such as the door lock mechanism and seat structure details, the silver color in fact granting it a special scratch-resistant characteristic that goes well with all those applications of the car interior.

Unlike conventional so-called ” wet ” oils and greases, these dry coatings (AFCs) can provide a clean, dry lubricating film to optimize surface friction and wear control, reducing noise and for greater comfort and smoother operation.

The following is a table summarizing the characteristics of two Molykote anti-friction coatings,

ask the expert

the one best suited to your needs

|

Properties |

Unit |

Molykote D-708 |

Molykote D-709 |

|

Color |

Black |

Silver |

|

|

Composition |

Solid lubricant Polytetrafluoroethylene (PTFE) in a solvent-based resin |

Solid lubricant Polytetrafluoroethylene (PTFE) in a solvent-based resin |

|

|

Viscosity iwata |

sec |

8 |

8 |

|

Non-volatile content |

% |

28.5 |

29 |

|

Density |

g\cm3 |

0.95 |

0.96 |

|

Drying time 80°C |

min |

5 |

5 |

|

Drying time 180°C |

min |

60 |

60 |

|

Coverage |

m2\kg |

19 |

19 |

|

Shelf-life |

months |

6 |

12 |