What is wear and tear and how can it be prevented?

Tribology is the science that studies the friction, wear and tear, and lubrication of contacting surfaces, in a given movement. It is based on concepts from materials science, chemistry, physics and other disciplines making it, indeed a multidisciplinary domain.

Wear and tear is a major concern for manufacturing industries, causing more than 50 percent of the loss of performance of production machines. Therefore, controlling the conditions that affect it would prevent machine failure and ultimately enable the industrial process to be optimized.

But before we start emphasizing how wear and tear should be prevented, we should ask ourselves…what exactly is wear and tear?

What is wear and tear?

Wear and tear can be defined as the damage or removal of material that a solid surface has suffered due to sliding, rolling, or impact against the surface of another solid. This is not a property of the material, but rather a response of the system.

Wear and tear leads to increased friction to material failure or loss of function. Therefore, in order to reduce wear (and consequently friction) a thin layer of lubricant must be sandwiched between the rubbing surfaces.

Wear and tear can be classified according to how surface damage occurs.

- Adhesive wear

- Abrasive wear

- Surface weakening

- Fretting

- Erosion wear

- Corrosion and oxidation wear

Each type of wear is caused by one or more mechanisms. These mechanisms can overlap synergistically, leading to an increased wear rate.

Types of Usury

In this section, more details are provided on each of the types of wear listed. The most common are Adhesive Wear and Abrasive Wear; but the other types of wear can also occur in many industrial applications under certain conditions.

ADHESIVE WEAR.

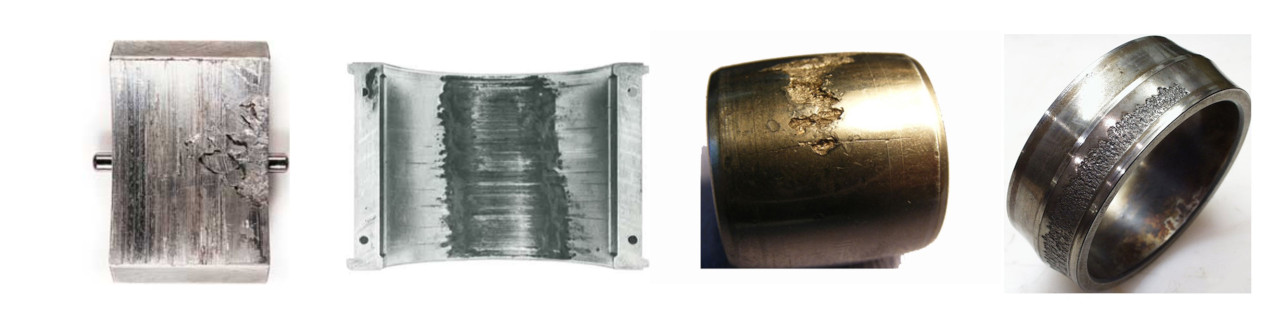

‘Adhesive wear is the type of wear originating from the contact and interaction of asperities between two surfaces in contact with a strong adhesive force. In other words, the opposing asperities bind to each other and detach when one surface slides over the other. Its intensity depends on several physical and chemical factors, but it will generally increase with higher values of surface energy density. The presence of lubricants and lower loads, however, will reduce its effect.

Fig. 1

Material removal during adhesive wear.

ABRASIVE USE.

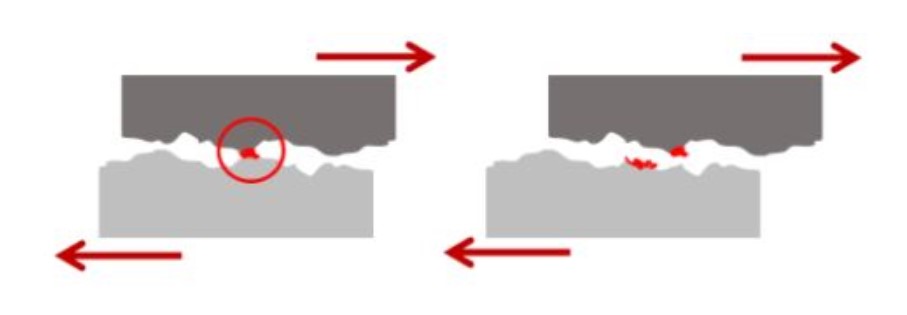

Abrasive wear occurs when a rough, hard surface slides over a relatively soft surface. This is the type of the most frequent wear mechanism found in industry. Abrasive wear can be produced by following three types of mechanisms, viz. plowing (if there is no removal of material from the surfaces, but rather, grooves are formed from the material being moved) cut (if removal of material in the form of debris occurs) or for fragmentation (if there is removal of material, and at the same time there is localized fracture of contact surfaces caused by the removed debris).

Fig. 2

Material removal during abrasive wear.

SURFACE WEAKENING

Surface fatigue is the type of wear in which the surface of a material is weakened by continuous loading. This is produced when wear particles are separated from solid surfaces by the accumulation of micro-damage of material. The wear mechanism in action combines the formation of cracks and voids in solid surfaces, which are amplified with continuous loading.

FRETTING

Fretting occurs between two soldal surfaces that come into contact in a constant, cyclic rubbing of small amplitude. It triggers weakening cracks, which often result in fretting weakening cracks.

EROSIVE USURE

Erosive Wear is the type of wear produced by a short sliding motion in a very short time interval. It is produced when particles gradually remove material from the surface by continuous impact, deforming and damaging it. The impact of Erosive Wear can be influenced by the nature of the impacting particles (size, strength, and hardness) as well as the speed and angle at which they impact the surface with each other.

CORROSION AND OXIDATION WEAR

‘Corrosion and oxidation wear occurs as a combined effect of chemical and mechanical action. Chemical action increases the porosity of the surface, while mechanical action leads to wear. There are also a number of factors that influence wear and tear here, such as improper design of the mechanism or inability to remove sufficient heat or moisture from the contact region.

How can wear and tear be prevented?

There is a wide range of methods to prevent Wear. The most common thing to do is to use wear-resistant materials or change the properties of materials in contact with surfaces. The latter can be done for example through hardening or chemical modification of surfaces. When this is not possible, modern oils and fats provide a quick and easy solution. A very wide selection of lubricants is currently available on the market, each designed specifically for a particular need or industrial application and compatible with The most common materials.

We are your technical partner.

If you have questions or would like to learn more about the possibilities for your industrial application, please fill out the contact form and one of our experts will contact you.