Applications for industrial lubricants

Lubricants for High Temperature

High operating temperatures, can cause deterioration of the lubricant. Contact us and we will advise you in choosing the best high-temperature lubricant for your applications.

Introduction

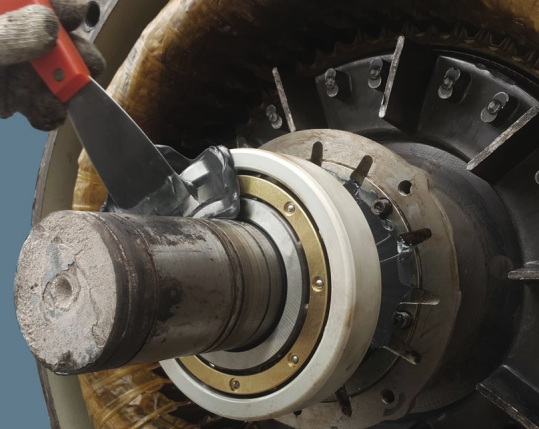

A layer of lubricating oil or grease is present in any mechanical component such as bearings, engines, transmissions, gas turbines and industrial machinery in order to protect them.

During machinery operation, heat is generated on the lubricating film, which can have two origins:

- Internal, if generated by the friction of mutually sliding parts, during normal operation.

- External, when it comes from a heat source outside the machinery.

High operating temperatures can cause the lubricant to deteriorate and consequently ruin mechanical components

High-temperature lubricants are formulated to function in extreme heat conditions. In addition, they can help reduce wear and extend the service life of mechanical components by maintaining lubricating properties even under high temperature conditions. The choice depends on the specific needs of the application and operating conditions, which is why the Mascherpa team is ready to help you choose high-temperature lubricants tailored to your needs.

Products

All products for High temperatures

Filter products by their attributes: brand, technology, applications…

Reference categories for High temperatures

Continue browsing the Mascherpa site

Latest articles on High temperatures

Sign up for newsletter to receive upcoming articles

Krytox™ GPL 226: anticorrosive grease for Oil & Gas

Silicone ablative materials for aerospace and defense

Lubricating paste: optimal performance and protection

Read PDFs on High temperatures

- There are no PDFs yet for:

High temperatures , ask the expert if you need an SDS or Data Sheet