Applications for industrial lubricants

Lubricants for screws and threaded connections

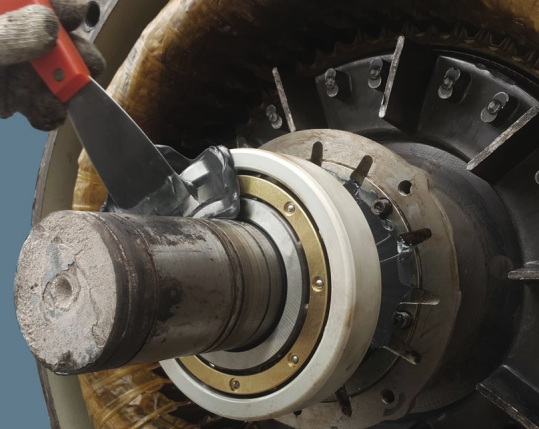

A good lubricant can reduce friction and pressure on screw contact points and threaded connections. Request information from the Mascherpa team to clarify your concerns

Introduction

Screws and threaded connections are used to fasten and join mechanical components together. They allow convenient disassembly, repeated use, and accurate reassembly. They also come in a variety of materials, including steel, stainless steel, aluminum, and copper.

Prevent thread damage

- Using a screw lubricant can help reduce rotational resistance. In addition, a good lubricant can also reduce friction and pressure on contact points, thus reducing the risk of thread damage.

Extends the life of your threaded screws

- In general, the use of screw lubricants can improve efficiency and extend the life of screws and threaded connections.

Products

All products for Screws and threaded connections

Filter products by their attributes: brand, technology, applications…

Reference categories for Screws and threaded connections

Continue browsing the Mascherpa site

Latest articles on Screws and threaded connections

Sign up for newsletter to receive upcoming articles

Molykote P-3300: the new anti-seize paste

Molykote dry lubricants: benefits and applications

Spray lubricant: a guide to types and applications

Lubricating paste: optimal performance and protection

Molykote HP-300: lubricant for the hydrogen industry.

MOLYKOTE® lubricating greases for the oil industry.

Proper pipeline lubrication: the Molykote anti-seize pastes

Read PDFs on Screws and threaded connections

Video

Subscribe to our YouTube channel