Safe anaerobic adhesives: discover the Arkema Born2Bond range

As the number of applications of engineering adhesives increases, new challenges arise that must be solved with respect for the environment, health and safety regulations. In response to these needs, Arkema seeks to develop specific new bonding techniques with safe anaerobic adhesives.

What are anaerobic adhesives?

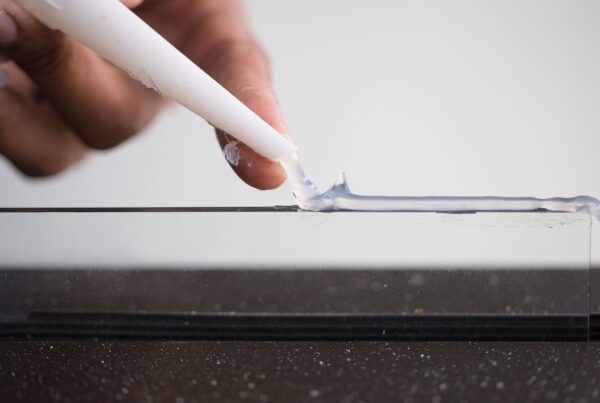

Anaerobic adhesives are single-component adhesives with an anaerobic reaction that, as can be understood from their name, cure in the absence of air; despite this, however, they need contact with metals.

Following polymerization, they are transformed into a thermoplastic resin that allows uniform and efficient transmission of stresses and vibrations.

Anaerobic adhesives have certain characteristics:

- Non-flammable

- Easy to apply

- Polymerization at room temperature

- Wide range for different resistances required

- Easily automated dosing

- Monocomponents

- Solvent-free

And they feature typical applications:

- Production of gears

- Engines and powertrains

- Pumps and compressors

Arkema Born2Bond™ Safe Anaerobic Adhesives.

The Born2Bond™ range of high-performance anaerobic adhesives has been formulated with environmental sustainability and workplace safety regulations in mind. These products, which are ideal for fastening and sealing processes (thread locking, pipe sealing, fixing and making gaskets) offer a reliable and cost-effective alternative to mechanical fasteners. Excellent resistance to impact and vibration, leakage and corrosion, along with high first breakaway torque, make them appropriate for both precision machining and heavy engineering. By replacing a large inventory of traditional components (washers, seals, pins, hemp, tapes), they can also help improve efficiency and effectiveness and reduce possible waste. Keeping with our commitment to create solutions that are always safer for users and better for the environment, the adhesives are solvent-free and selected ranges are NSF certified. An anaerobic range without safety labeling specifically designed to improve the working environment and facilitate HSE evaluation of a new product without compromising performance is also under development.

Process improvement and safety at work

Born2Bond™ works based on a primary respect for the environment and the workplace, in fact their fundamental goal is to develop sustainable adhesives and production methods and protect the welfare of customers with:

- Energy-efficient application processes

- Increased user comfort

- Preventive maintenance

- Anaerobic range without safety labeling

Arkema Born2Bond™ anaerobic adhesives, such as Born2Bond™ Pipe Sealing PA-77, are designed in order to reduce and eliminate hazardous substances or those that may pose a risk to the health and safety of product users.

We at mascherpa can say that Arkema Born 2Bond™ anaerobic adhesives improve production safety in application and end use.