Brands

MG Chemicals

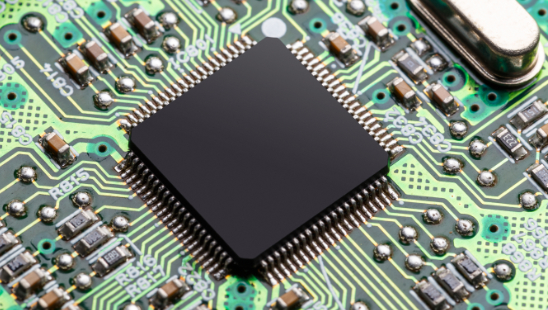

Shielding, protection and bonding for electronic products.

MG Chemicals: electrically conductive paints, electrically and thermally conductive adhesives

MG Chemicals has been providing advanced solutions for electronics for more than 60 years, specializing in high-efficiency conductive paints and adhesives. The products provide EMI/RFI shielding and ESD protection, ensure strong electrical connections, and are ideal for circuit repairs and sensitive component fastenings. In addition, the available adhesive ranges facilitate bonding and thermal management in complex applications without the need for mechanical fasteners.

Conductive paints

- Conductive paints combine a non-conductive resin binder and an electrically active pigment to offer advanced solutions in EMI/RFI shielding and ESD protection. Formulated with fillers such as branched carbon powder, nickel flakes, silver-plated copper, and silver, they ensure optimal performance for various frequencies and corrosion resistance.

- Available binders such as solvent-acyclic, water-based, epoxy and urethane ensure adhesion, durability and versatile applicability. The properties of conductive coatings are useful for grounding, prototyping, and galvanic corrosion protection.

Electrically conductive adhesives

Conductive adhesives ensure strong electrical connections on surfaces where soldering is not possible. They offer excellent electrical and thermal conductivity, high chemical resistance and mechanical stability, making them ideal for circuit repairs and bonding of sensitive components. These adhesives are available in different formulations and are suitable for many applications such as, for example, bonding LEDs and components to PCBs.

Thermally conductive adhesives

MG Chemicals’ thermally conductive epoxy adhesives are designed to provide effective and durable bonding a bonding of heat-generating electronic components, such as heat sinks, LEDs, and power modules. Available in single-component versions, which require no mixing, and two-component versions with a 1:1 mixing ratio, these adhesives provide excellent thermal conductivity and electrical insulation, adapting to a variety of processing needs.

One-component epoxy adhesives

Single-component epoxy adhesives simplify production with easy application without mixing and unlimited processing time. With low- to moderate-temperature curing and long shelf life, they offer excellent adhesion to various substrates, ideal for SMT assembly, chip bonding, LED manufacturing and telecommunication devices.

Products

All products MG Chemicals

Filter products by their attributes: brand, technology, applications…

Latest articles MG Chemicals

Sign up for newsletter to receive upcoming articles

Electrically Conductive Epoxy Paint and Adhesives: Various Applications

Mascherpa at Focus on PCB 2025: the Best of the Trade Show

Mascherpa at the Focus on PCB 2025 exhibition: advanced PCB solutions

Read PDFs MG Chemicals

- There are no PDFs yet for:

MG Chemicals , ask the expert if you need an SDS or Data Sheet

Industries

Discover the industries of reference for MG Chemicals