Key Points

- Lubricant grease compatibility is a fundamental factor in preventing failures and unplanned downtime.

- Mixing lubricant greases with different thickeners can cause loss of consistency, oil separation, and increased wear.

- The effects of incompatibility are not always immediate, making timely diagnosis of the problem difficult.

- The ASTM D6185 test is the reference method for evaluating compatibility between two lubricant greases.

- Proper management of lubricant grease changes reduces risks and ensures reliable performance over time.

Lubricant grease compatibility is essential in industrial maintenance to avoid failures caused by incompatible mixtures.

Index

- What happens when different lubricant greases are mixed?

- Negative effects of mixing incompatible lubricant greases

- How to determine if two lubricant greases are compatible

- What to do if lubricant greases are not compatible

- Prevention is key for changing lubricant greases

- FAQ

- Compatibility between lubricant greases: an aspect not to be underestimated

What happens when different lubricant greases are mixed?

In industrial maintenance, selecting and applying the appropriate lubricant grease is essential to ensure the proper functioning and longevity of equipment.

Lubricant greases can be replaced for various reasons:

- performance improvement;

- changes in operating conditions;

- replacement of discontinued products.

However, what happens if the new grease mixes with the previous one? This article analyzes the risks of mixing incompatible lubricant greases, how to verify their compatibility, and what measures to take during the transition between products.

Negative effects of mixing incompatible lubricant greases

Mixing lubricant greases with different compositions can cause negative effects that compromise both the lubricant’s performance and the equipment itself. The main factor of incompatibility is usually the thickener.

When mixing lubricant greases with incompatible thickeners, the following effects may occur:

- excessive softening or, in some cases, hardening outside the specified NLGI range;

- oil separation;

- leaks in seals;

- increased operating temperature;

- greater component wear due to the loss of lubricating properties.

These effects are not always immediate, which can make early diagnosis difficult. Therefore, it is essential to anticipate and verify the compatibility before making any changes.

How to determine if two lubricant greases are compatible

There is no single universal source for the compatibility of lubricant greases. There are compatibility tables published by manufacturers and technical organizations, but they do not always agree with each other. This is due to the variety of formulations available on the market, even within the same type of thickener.

For this reason, the best way to determine compatibility between two lubricant greases is through specific laboratory tests. The most recognized method is the ASTM D6185 test, which evaluates the binary mixture of two lubricant greases.

What does the ASTM D6185 method involve?

The objective is to simulate the mixing between an existing lubricant grease and a new one and determine if this combination will negatively affect the lubricant’s performance.

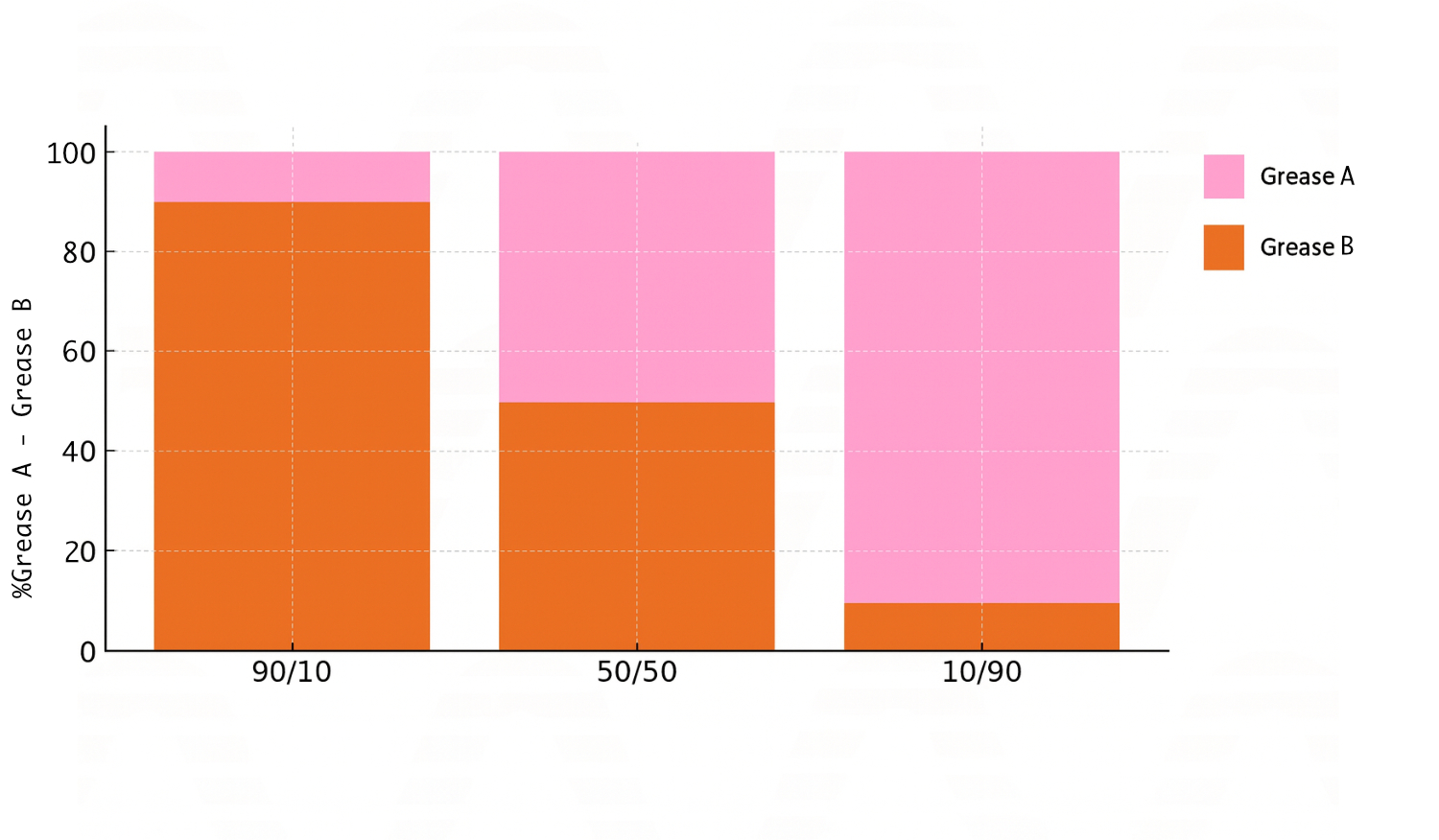

During the test, three mixtures are prepared with different proportions of existing grease and new grease:

- 90:10

- 50:50

- 10:90

These proportions represent different situations that may occur, from initial relubrication to complete replacement with remaining residues.

Each mixture is tested for:

- Thermal stability: analyzes the behavior of the lubricant grease when exposed to high temperatures, identifying if it loses consistency, separates oil, or degrades its structure.

- Shear stability: measures the resistance of the lubricant grease to loss of consistency under mechanical stress, such as those occurring in bearings or gears.

- Storage stability: evaluates how the properties of the mixture change after a period of extended rest, simulating real storage conditions.

The results are compared with the values of pure greases. If the parameters remain within acceptable limits compared to the original products, both lubricant greases are considered compatible.

What to do if lubricant greases are not compatible?

When a grease change involves incompatibility, it is essential to follow certain steps to minimize risks:

1. Removal of existing grease

It is advisable to manually remove at least 90% of the existing lubricant grease before introducing the new product. This significantly reduces the potential negative effects of an incompatible mixture.

This proportion is also validated by the 90:10 test result of the ASTM method.

2. Gradual lubrication

Once the new lubricant grease is introduced, it is advisable to apply half the usual volume, but with double the frequency during the initial lubrication cycles. This procedure facilitates theexpulsion of residues of the previous grease and ensures a more controlled transition.

Prevention is key for changing lubricant greases

Changing lubricant grease without verifying compatibility can cause failures and unplanned downtime Therefore, it is recommended to:

- consult the technical data sheets of both lubricant greases;

- contact a specialized laboratory to perform the ASTM D6185 tests;

- implement cleaning protocols and progressive relubrication if compatibility is not guaranteed.

FAQ

Is it possible to mix different lubricant greases?

It is not advisable, as they may be incompatible and lose their properties.

What happens if I mix two incompatible lubricant greases?

Oil separation, softening or hardening may occur, reducing the effectiveness of lubrication.

How can I determine if two lubricant greases are compatible?

It is necessary to consult the manufacturer’s compatibility table or perform laboratory tests. The Mascherpa experts are at your service for all solutions regarding compatibility between lubricants and thickeners.

What risks does using an unsuitable mixture in machinery pose?

It increases wear, the risk of premature failures, and possible unplanned shutdowns.

What is the best procedure for switching from one lubricant grease to another?

Thoroughly clean the system and remove the previous lubricant grease before applying the new one.

Compatibility between lubricant greases: an aspect not to be underestimated

As seen throughout the article, compatibility between lubricant greases is not a minor detail but a determining factor in ensuring consistent performance, component protection, and operational continuity.

Incompatible mixtures, unassessed product changes, or choices based solely on generic parameters can compromise the lubricant’s behavior over time and increase the risk of failures or plant shutdowns.

For this reason, every maintenance intervention should start with an accurate technical analysis of the application and operating conditions. In case of doubts or to delve into a specific situation, it is possible to contact our Mascherpa experts, who offer specialized expertise and field experience to support truly effective choices.