Key Points

- I fire-resistant hydraulic fluids are critical to ensuring the safety of steel plants, reducing the risk of fire and ensuring operational continuity even under extreme conditions.

- Solutions HFC and HFDU Condat offer high performance due to their thermal resistance, oxidation stability and environmental compatibility, keeping hydraulic circuits clean and reliable.

- I high temperature technical greases protect bearings, couplings and gearboxes from wear, vibration and contaminants, extending component life and reducing maintenance costs.

- I universal high-performance greases simplify lubrication management due to their versatility, reducing inventory and improving overall system efficiency.

- The integrated lubrication for steel mills, combining hydraulic fluids and Condat greases, ensures safety, energy efficiency and sustainability throughout the production cycle.

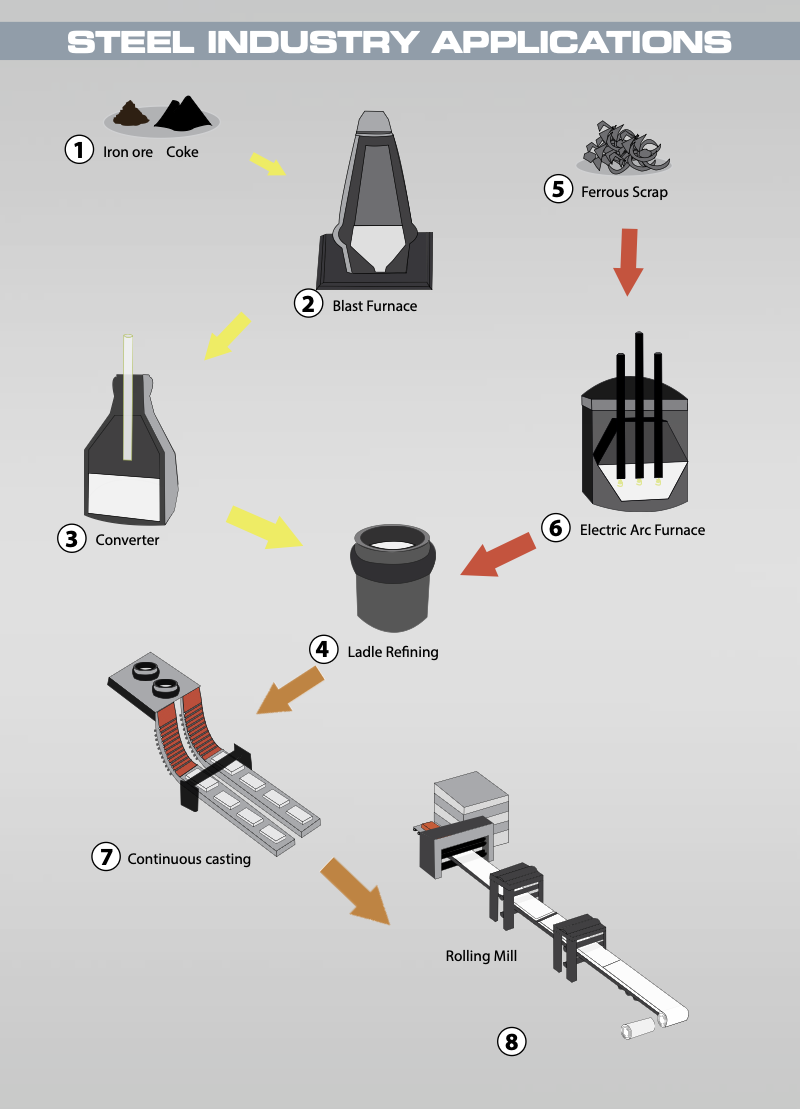

The steel industry is one of the most challenging contexts in which a lubricant can operate. Electric ovens, continuous casting, rolling mills e presses work at temperatures which may exceed the 1.500 °C, with high loads, contaminants and constant risk of fire.

For more than a century Condat, partners Mascherpa, develops dedicated solutions for this sector. The range of Condat steel mill lubricants is designed to offer the maximum protection at the most critical points of the plant, optimizing consumption, efficiency e durability Of the components. The range includes:

- Fire-resistant hydraulic fluids;

- technical fats;

- Universal high-performance greases.

Fire-resistant hydraulic fluids

In the steel mills, where the proximity of sources of heat and systems at high pressure involves risk of fire, i fire-resistant hydraulic fluids are essential for the security of thefacility and of the operators.

These products must offer a balance between lubrication, thermal stability, resistance to oxidation and ability to limit the spread of flames, while at the same time maintaining cleaned the plumbing e stable pressures of operation.

Fire-resistant hydraulic fluids fall into two main categories: water-based fire-resistant fluids (HFC) and synthetic fire-resistant fluids. (HFDU). Both types meet the international safety standards, such as the FM Global certification, and meet the requirements of the ISO 12922 standard, which regulates the characteristics of hydraulic fluids for environments with high risk.

Water-based fire-resistant fluids (HFCs)

HFC hydraulic fluids combine water and glycol in a solution that provides excellent fire resistance and good lubricating properties. The presence of water, which represents about the 40-45% of mixture, naturally reduces the fire risk, while the selected additives offer protection against corrosion, oxidation e foaming.

The Condaguard C46, for example, is an advanced water-glycol hydraulic fluid, biodegradable e compatible with elastomers, pumps e valves. Its color fluorescent green makes it easy to monitor the level in the tank and detect any leaks, improving the safety in operation.

Also theHydrosol 207 belongs to the same category and is distinguished by its remarkable chemical stability and excellent anti-foaming behavior, qualities that make it particularly suitable for plants for lamination e casting processes.

These hydraulic fluids are used in plant areas where the fire protection is a priority, such as in the hydraulic systems in electric arc furnaces, rolling mills and continuous casting units.

Synthetic fire resistant fluids (HFDU)

HFDU flame retardant fluids. represent the most advanced solution for steel mill hydraulics. They are. synthetic hydraulic oils fully anhydrous, self-extinguishing and biodegradable, formulated with ester bases e polyether polyol. In addition to ensuring a excellent protection againstwear and tear and corrosion, they maintain stable viscosity even as the temperature, preventing pressure drops and reducing energy losses.

Products such as. Condat D 46 e Condat D 68 are internationally recognized for their performance and the FM Global certification, which attests to their safety In case of fire. The variant Condat D 946, always of the synthetic ester, is designed for hydraulic systems at high pressure subject to fire hazards, ensuring high resistance to oxidation and aneffective cleaning of the system.

Thanks to their stability e environmental compatibility, i hydraulic fluids HFDU Condat are used in applications such as the adjustment of electrodes in electric furnaces, i opening systems e closing of vaults of the ladle furnaces and the lines of hot and cold rolling.

Technical greases

If the hydraulic fluids represent the heart of motion systems, i technical greases are what protects e prolongs the life of the mechanical components most stressed. In a’ steel mill, bearings, presses, couplings and gearboxes must work under conditions of intense heat, dust and water, while maintaining efficiency and reliability.

The Condat Formula FV is designed for the continuous casting bearings and offers a constant lubrication also under high loads, reducing thewear and lengthening maintenance intervals. The GR 266, on the other hand, is formulated to hydrostatic presses e rolling mills and ensures a durable and stable lubricating film also in presence of water, ensuring protection and duration to the mechanisms.

The Condat range also includes solutions for couplings and gearboxes, such as the Couplex 462 EP1, designed to resist centrifugation and penetrate deep into mechanisms, reducing leakage and improving sealing.

These products, free of heavy metals, combine high performance with a reduced environmental impact, in line with the latest environmental care requirements in ‘heavy industry.

Universal high-performance greases

In large production lines, where lubrication points are numerous and differentiated, it is useful to be able to rely on universal greases capable of cover multiple applications with asingle formulation. I Condat high-performance universal greases are characterized by ahigh resistance to extreme pressures, excellent mechanical stability e great versatility of use.

The LI CA 152 EPV, for example, is a multipurpose grease also suitable in the presence of water, which makes it possible to reduce inventories and simplify maintenance management.

Other products such as theAkronex 172 HBGB, which can be used up to 160 °C, and the GR 130 EP, with base oil at high viscosity e solid additives, complete the range for the most stringent requirements.

These fats ensure anexcellent adhesion, longer refill intervals longer and an overall reduction in fuel consumption, contributing to a more efficient and sustainable maintenance.

Applications in the steel industry

Electric arc and ladle furnaces: handling e hydraulic controls require HFC fire resistant hydraulic fluids o HFDU, as Condaguard C46 o Condat D 46, which guarantee security against the fire risk e stability of the system.

Ladle refining: i tilting systems e opening of times rely on HFDU synthetic fluids, capable of withstanding high temperatures and maintain a constant viscosity even during thermal peaks.

Continuous casting: i bearings and the guides require technical greases high-performance greases such as Formula FV, which ensure constant lubrication e protection against wear and tear.

Hot and cold rolling mills: the combined use of Condat D hydraulic fluids e universal greases such as the GR 130 EP allows you to maintain ahigh operating efficiency, minimizing the plant downtime.

Reducers and couplings: specific greases such as Couplex 462 EP1 ensure a stable lubrication even in the presence of vibrations e extreme mechanical loads, improving the durability of the components.

Coke fuel and blast furnace: the operations of loading and transport of coke, as well as theopening and closing of the blast furnace doors, require fire-resistant hydraulic fluids HFC such as Condaguard C46, which can ensure reliable lubrication and prevent fire hazards near high temperatures.

Converter and ferrous scrap: In systems of handling and platforms scrap lifting, the HFDU hydraulic fluids such as Condat D 46 offer protection againstwear and tear and guarantee operational stability even in the presence of dust and metal contaminants.

FAQ

What are hydraulic fluids?

What are the hydraulic fluids?

Discover Condat’s range of lubricants for the steel industry

The lubrication in the steel industry is a key determinant of safety e efficiency Of the plant. From the choice of fire resistant hydraulic fluids to high temperature technical greases, each product plays a specific role in keeping stable and productive the entire operating cycle.

The Condat range, offers solutions designed for every industry need: from electric furnaces to rolling lines, each application strikes a balance between performance, reliability and environmental friendliness.

To further explore the topic of lubricants for steel mills and find out how to choose the most suitable product for the specific conditions of your plant contact our experts Mascherpa.