The application of the conformal coating is a critical process to ensure the protection of printed circuit boards (PCBs), especially in harsh environments wheremoisture, vibration, and contaminants can affect the operation of electronic devices. However, improper application of conformal coating can drastically reduce the benefits of this protection, leading to premature failures and defects that are costly to correct.

The importance of conformal coating PCB

Conformal coating is designed to provide additional protection to PCBs, improving their resistance to harsh environmental conditions. Not all devices require a protective coating, but for those exposed to moisture, temperature extremes, chemicals or mechanical stress, it becomes an absolute necessity. Theelectrical insulation provided by conformal coating has enabled the design of more complex and reliable PCBs.

Conformal coating cannot, however, solve pre-existing design or production problems. In fact, if the PCB already has defects, conformal coating can even amplify them. It is therefore essential that the application process be carried out with precision, starting with a thorough analysis of the operating environment and compatibility between the materials used.

Some of the common problems in conformal coating application and how to solve them

Several problems can occur during conformal coating application that compromise coating effectiveness, durability, and reliability of the final product.

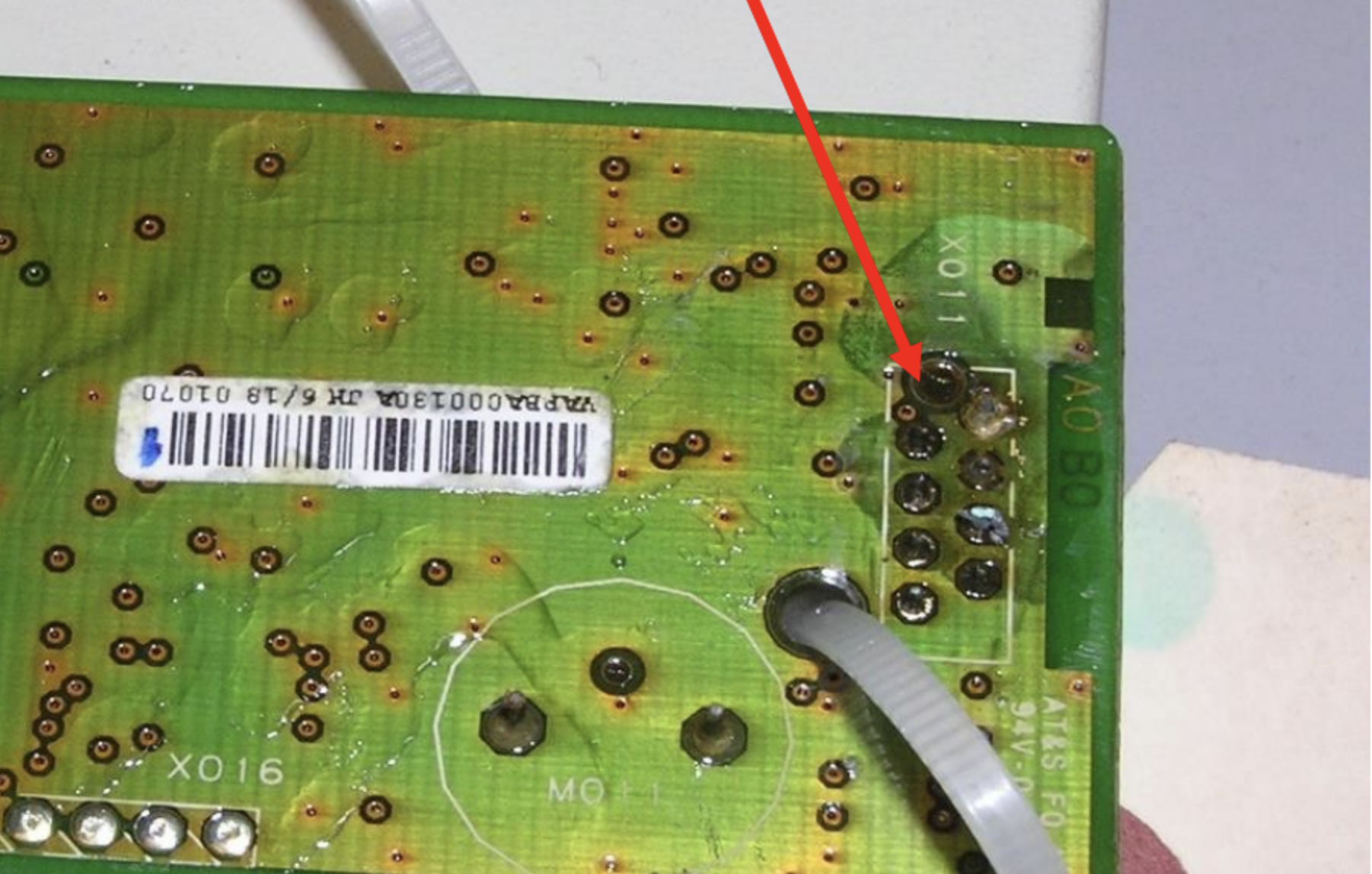

Corrosion

Corrosion is a phenomenon that occurs due to a chemical or electrochemical reaction between a material and its environment, leading to deterioration of the material. This phenomenon leads to the formation of dendrites, which are one of the main causes of failure in electronic devices.

The causes of corrosion arise from contaminants on the circuit surface from board fabrication, components, assembly equipment, and solder residues.

To prevent corrosion, athorough inspection of the circuit board should be performed and gloves should be worn during handling to prevent the transfer of contaminants. In addition, constant inspection and maintenance of machinery is essential.

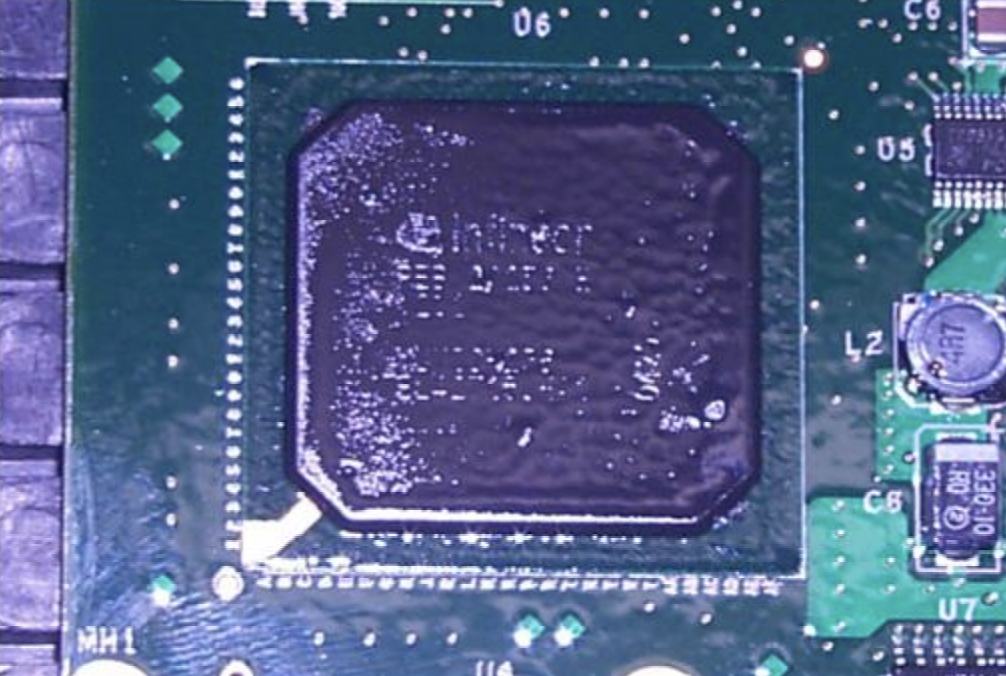

Air bubbles

This phenomenon, one of the most common in the application of conformal coatings, occurs when air becomes trapped in the coating, creating visible defects that compromise protection. Bubbles can lead to the formation of a foam that makes the coating uneven. Bubbles in conformal coating compromise insulation and create weak points in the coating.

Bubble formation in conformal coatings can be caused by several factors, including air entrapment during transfer into the pressure vessel, incorrect pressure regulation in the spray system,too rapid drying, accelerated curing, and excessive viscosity of the material.

To prevent and solve this problem, it is essential to optimize every step of the process: from choosing a formulation with appropriate viscosity and solvents, toapplying in thin, progressive layers, to precisely controlling pressure and airflow. In addition, careful management of the drying stage enables proper evaporation of solvents and the formation of a uniform, defect-free coating.

Orange peel

Anorange peel effect occurs when the coating is uneven and dull. This aesthetic defect can impair the functionality of the coating, reducing circuit protection. The main causes of this phenomenon are related to incorrect application of the material, inadequate thickness of the protective film, lack of homogeneity in deposition, and incorrect profiling.

To reduce this effect, it is essential to decrease the viscosity of the covering material and properly adjust the air pressure of the spray valve. Another aspect to consider is the thermal profile.

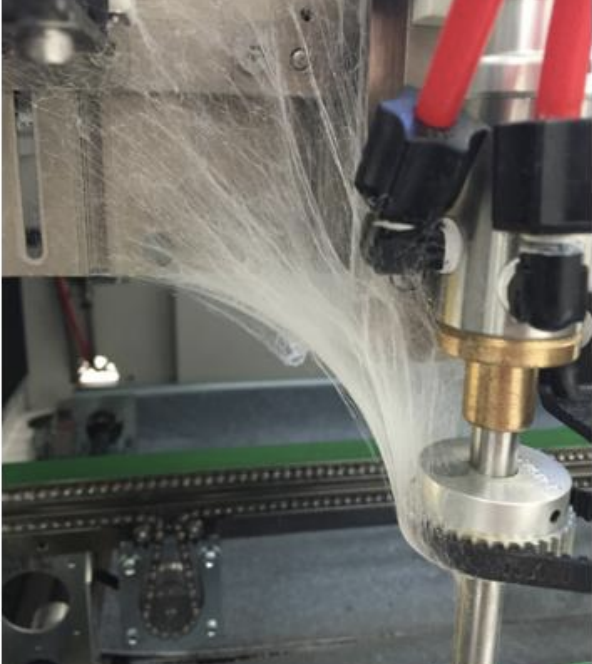

Cobwebbing

One of the most common problems in the application of conformal coating is the phenomenon known as “cobwebbing,” which is manifested by the formation of thin, translucent filaments when spraying the coating, due to it drying too quickly in the air before reaching the surface. The main causes of this defect include too high a viscosity of the coating, excessive air pressure that over-atomizes the material, and theuse of rapidly evaporating solvents that promote premature drying.

To avoid this phenomenon, it is essential to adjust the coating viscosity, set the air pressure correctly, and choose solvents with an evaporation rate appropriate for the working environment. In addition, controlling environmental conditions can help avoid overly rapid drying and ensure a more uniform conformal coating application.

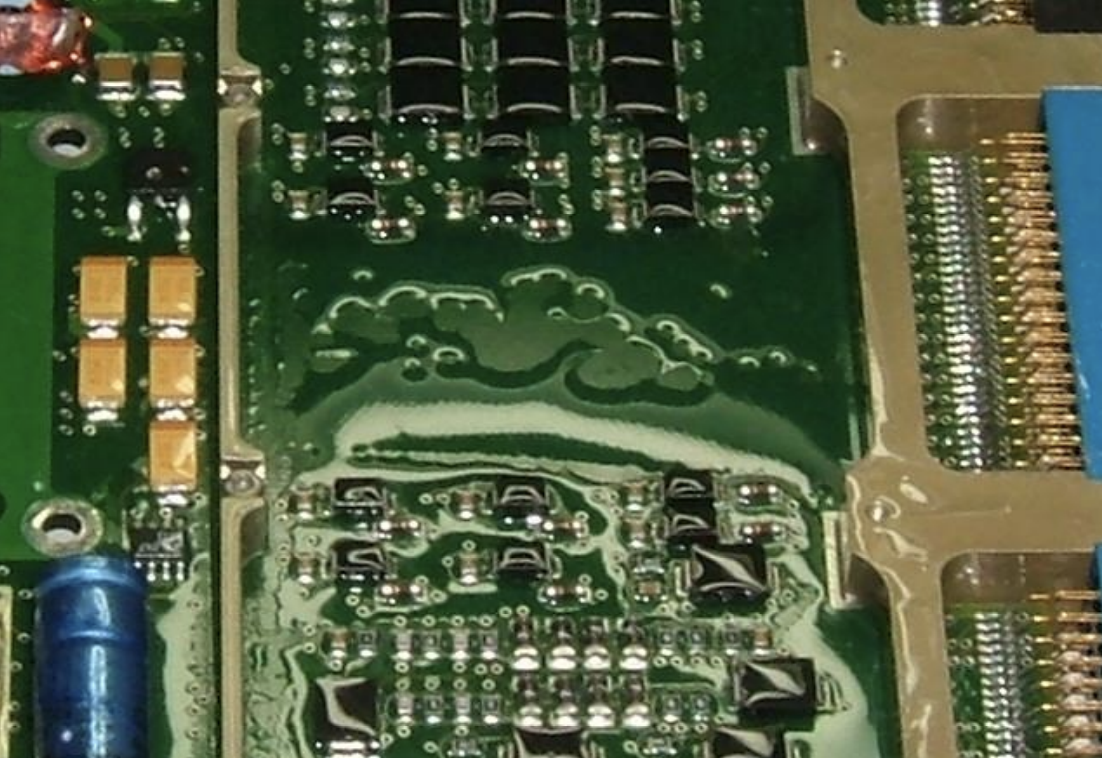

Dewetting

Dewetting occurs when conformal coating does not properly dispense onto the surface of the printed circuit board (PCB), creating bare areas that compromise circuit protection. This problem is caused by low surface tension of the solder resist or components, the presence of contaminants, or inadequate cleaning of the substrate. Excessive dilution of the conformal coating can also contribute to poor adhesion. To ensure proper wettability of the conformal coating pcb, it is important to thoroughly clean the PCB and use a primer or plasma treatments.

Delamination

Delamination occurs when the protective film peels away from the PCB, leaving the area underneath exposed and compromising the protection of the PCB. This problem can be caused by low surface tension of the solder resist, inadequate cleaning of the circuit board, or lack of compatibility between the coating and the PCB. To avoid this phenomenon, it is helpful to increase the surface tension of the PCB surface and remove contamination from the PCB.

Learn more about conformal coatings

Conformal coatings are fundamental elements when it comes to electronics and PCB protection for this reason it is important to know the different problems that can arise from wrong applications and material choices. In addition to those listed, many other issues can occur during the application of conformal coatings, such as the phenomenon of cracking, fisheye, capillary effect, dendrites and whiskers. To learn more about these issues and how to deal with them, come visit us at the Focus on PCB show and download the technical guide to better protect your PCBs.

We will also be present at the Focus On PCB fair in Vicenza on May 21 and 22, come visit us at our booth