Honeycombs: Nidaplast

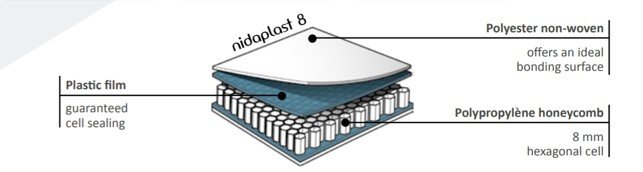

Nidaplast honeycombs are 8-mm polypropylene mesh honeycomb structures used as cores in structural sandwich panels.

The Nidaplast range can be used for applications with manual or cut-and-spray layering as well as RTM and infusion.

The surface of the honeycomb structure is coated with a polyester nonwoven that allows layering or bonding of virtually any material, for applications in various fields: construction, transportation, marine, industrial facilities, sports, etc. The heat-sealing of this nonwoven on the honeycomb structure ensures its perfect adhesion.

Polyester nonwoven is the ideal surface for impregnation with thermosetting resins as well as thermoplastic resins, cement, etc.

The plastic film present between the nonwoven and the nonwoven alveoli makes the latter watertight and thus limits the consumption of resin or adhesive.

Polypropylene, from which Nidaplast is made, is a durable and 100 percent recyclable material.

The honeycomb structure is composed of 95% vacuum, still ensuring high mechanical properties.

The range of Nidaplast honeycombs also includes applications designed for lightened marble panels (Nidapan) or to meet fire/smoke regulation requirements : Nidaplast 8FR is an extruded polypropylene honeycomb with approved, halogen-free material that limits flame spread.

(Extinguishing according to UL94 standards: class V2)

- The Nidaplast 8 product has the “Certificate of Naval Approval” issued by DNV. Germanischer Lloyd certificate.

- Large panels: 2500 x 1220 mm

- Different thicknesses: from 5 to 90 mm

- Size of the alveoli: 8 mm

- Indicative density for a 20 mm Nidaplast8 panel: 1.5 kg/m2

LIGHTWEIGHT

Nidaplast 8 is a lightweight material that encloses an air core.

The low weight allows for lighter structures while also making installation extremely easy.

It is an easy-to-cut material, thus extending tool life.

IMPUTRESCIBLE

Nidaplast 8 panels guarantee stable and durable realizations.

Unlike plywood panels, Nidaplast is insensitive to water and most solvents; if the surface is punctured, Nidaplast can neither swell nor rot.

HIGH RESISTANCE TO IMPACT AND COMPRESSION

Nidaplast is a viscoelastic material, so it has excellent impact resistance, allows progressive shock dissipation, resists fatigue, and avoids possibility of delamination.

THERMAL AND ACOUSTIC COMFORT

Nidaplast 8 composed of an air core contributes to the improvement of thermal comfort while also ensuring acoustic insulation.

ECONOMIC

To support the same load, with a given deflection, it is easier, lighter and cheaper to increase the thickness of Nidaplast 8 than to reinforce the coatings.

Nidaplast 8 honeycombs make it possible to optimize the composition of a sandwich panel without oversizing the coverings.