Lubricants for wind energy

Wind turbines contain many moving components that are prone to premature failure without proper treatment. In this article, we explore the trends, challenges and solutions of special lubricants in the wind power industry.

THE CURRENT SITUATION IN THE WIND POWER INDUSTRY

Wind energy is one of the fastest growing renewable energy sectors and a key area for sustainable development. As a result, it has become an important area for financial investment around the world, which is facilitating more innovative maintenance and repair processes and high-performance technologies.

Through increased efforts to alleviate climate change, energy production through renewable energy is set to grow 40 percent by 2022, according to the International Energy Agency. This progress is already underway in Europe, with 6.1 percent growth demonstrated in 2020 along with 111 GW wind turbines planned for installation in the coming years. This will increase the total cumulative installed capacity of wind power in Europe to over 300 GW by the end of 2030.

That said, there is still work to be done to achieve these goals; reduce operating and maintenance costs and improve durability.

CHALLENGES AND TRENDS IN LUBRICATION IN THE WIND POWER INDUSTRY

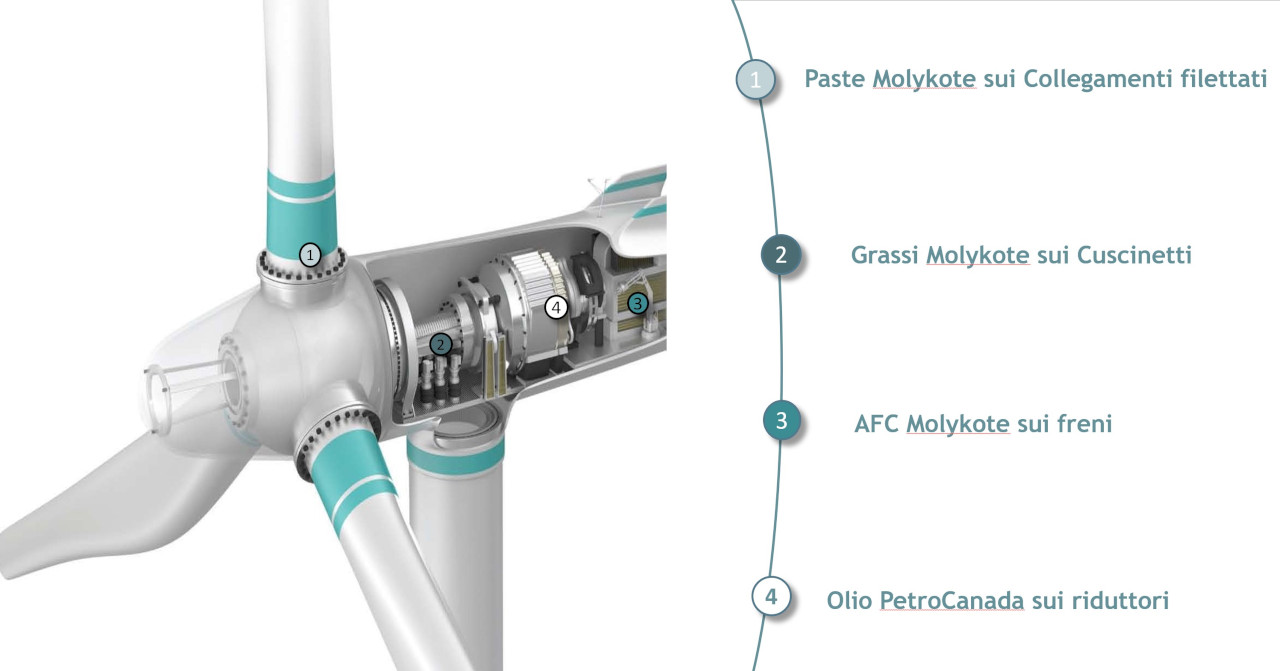

Moving elements within wind turbines include bearings (found in the main shaft, pitch, yaw, generator, and gearbox) and threaded connections (found in the tower and body that connect different elements together).

Failures often occur due to uneven distribution of loads and extreme environmental forces, such as wind speed. These factors can lead to excessive mechanical stress, load, temperature and pressure on the elements causing premature failure.

SOLUTIONS TO TRIBOLOGICAL CHALLENGES IN THE WIND POWER INDUSTRY

In this content we examine the use of Molykote pastes in threaded connections.

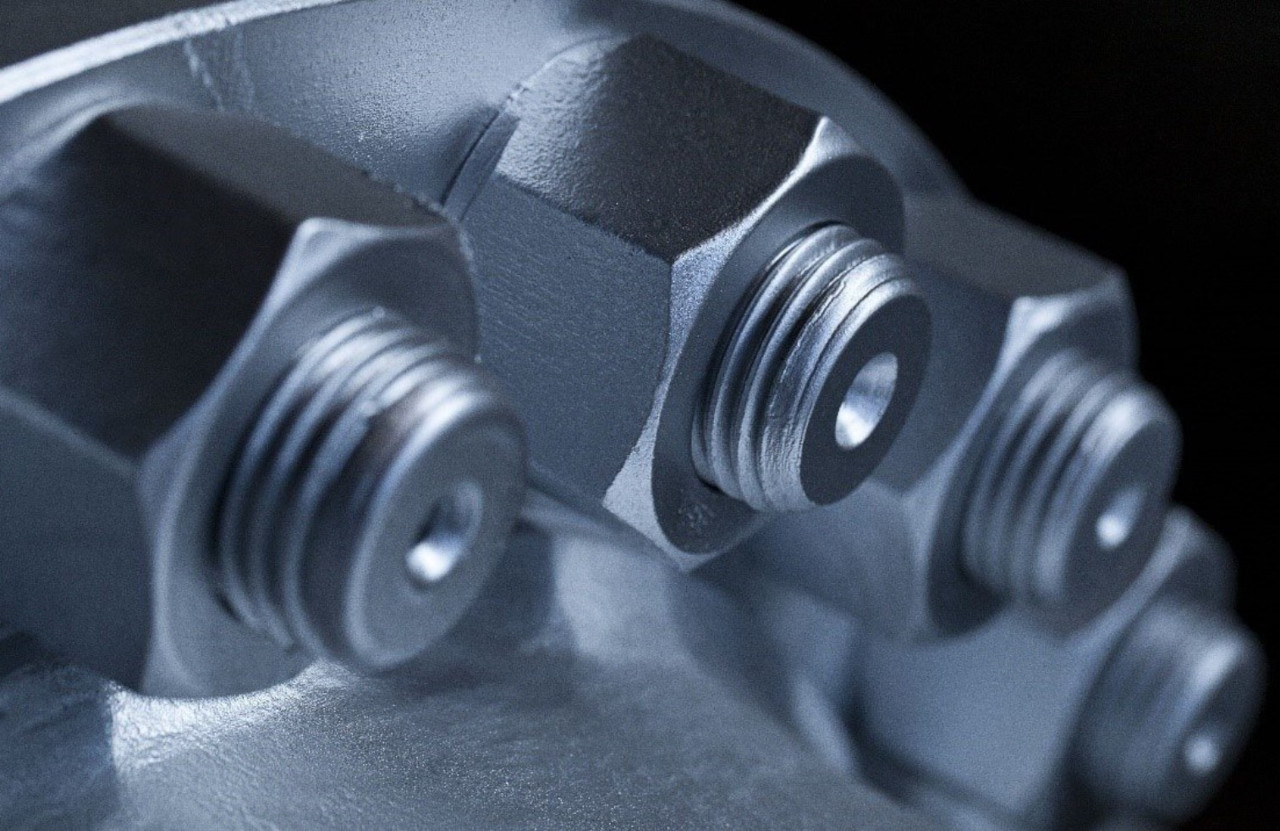

Safe and reliable wind turbines depend on strong threaded connections; proper lubricating paste helps improve the quality, safety, and reliability of the assembly with proper tightening. Prevent corrosion, avoid bolt failure and reduce service costs

Review our solutions for threaded connections

Tighten all assembly bolts to the required tension with the correct torque

: thread roughness creates uneven friction and incorrect tightening of bolts during installation. Lubricate threads with Molykote pastes to achieve a low and constant coefficient of friction, helping to ensure proper tightening and tension on all wind turbine assembly bolts.

Protect threaded connections for durability

: Bolts and fasteners on equipment joints must remain invulnerable to heat, cold, pollution, rain, snow and even salt spray. Apply Molykote pastes to provide threaded bolts with increased and long-lasting protection from corrosion and seizing.

Helps facilitate disassembly of threaded connections.

: corrosion, adhesion and seizing make disassembly difficult after long outdoor service. Use Molykote pastes for bolt lubrication, fretting corrosion protection and easy disassembly without damage.

Mascherpa provides high-performance lubricants for the wind industry designed to optimize your services .