Key points of the article

- The PoliMi Motorcycle Factory team is developing an electric racing motorcycle with advanced components designed for competitive environments.

- Mascherpa supports the project by providing lamination materials, technical consulting, and customized solutions.

- The prototype integrates carbon fiber and fiberglass parts, such as the battery underseat and the “board-box” for electronics.

- Production takes place in a clean room, with vacuum systems and optimized consumables.

- The collaboration is part of the NEXT program, which combines innovation, training, and technology transfer.

In the heart of the Polimi Motorcycle Factory laboratories, a new electric racing motorcycle is taking shape, designed to challenge the limits of technology and track performance. The team is working on an advanced prototype, with components made of composite materials, integrated electronic management systems, and innovative solutions designed for competition.

Mascherpa supports the team in choosing technical materials and production processes, offering concrete support at every stage of design and construction.

A New Chapter: from Thermal Prototype to Electric Project

After successfully completing an internal combustion prototype, the team has begun developing an electric racing motorcycle, introducing new solutions for motorcycle design, processing, and quality control.

Among the components already produced:

- The dashboard unit, complete with buttons and ignition, finished after post-lamination treatment;

- The frame molds, assembled after baking and curing phases;

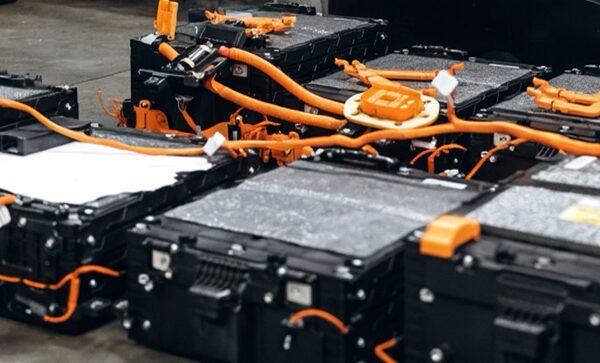

- The dry carbon underseat, designed to house inverters and Low Voltage batteries;

- The “board-box”, laminated in fiberglass, to house logical and electronic components with adequate electrical insulation.

These elements are part of a motorcycle construction strategy oriented towards the needs of a real competition, where weight, strength, and precision make the difference.

Advanced Lamination: High-Performance Processes

The productive heart of the project is the team’s clean room, where composite lamination operations take place. Here, every detail is optimized to ensure consistent and repeatable results. The team has implemented:

- Custom vacuum bags and release films, adapted to specific geometries;

- A new system for vacuum application to ensure a high level of depression, in order to obtain constant pressure control during curing;

- Workstations equipped with optimized consumables, electric fabric cutters, autoclave tubes, and cutting systems.

“This year we decided to raise the bar in every phase of the lamination process. New vacuum bags, release films, and auxiliary materials. A complete kit, tailored to our needs, essential for obtaining reliable and repeatable results.”

— PoliMi Motorcycle Factory

Mascherpa’s Contribution: Materials for Electric Competitions

In this new project as well, Mascherpa plays a key role in providing technical solutions for high-performance applications. The support focuses on:

- Lamination materials (vacuum films, release films, pumps, autoclave tubes, and accessories produced by Diatex);

- Composite materials for frame and fiber fairings;

- Technical consulting during the design and validation phases of components.

This collaboration falls within the framework of NEXT, Mascherpa’s program dedicated to transferring know-how to new generations of engineers and innovators in the sector.

An Event to Share Results and Future Visions

On September 19th, the Polimi Motorcycle Factory will officially present the 2025 prototypes at the Aula Magna Carassa and Dadda of the Politecnico di Milano. An anticipated moment, representing the synthesis of two years of work, testing, and innovation. It will be an opportunity to see up close the new electric motorcycles developed by the team and to engage with students, professors, and technical partners. Mascherpa will enthusiastically participate in this event, convinced that sharing achievements and perspectives is an integral part of the growth journey for new generations.

Conclusion

The new electric racing motorcycle developed by the PoliMi Motorcycle Factory represents a step forward in academic motorsport, where materials, design, and process control converge to create a competitive and high-performance vehicle. Mascherpa is proud to support this project, contributing with technical expertise and concrete application solutions.

Contact Mascherpa experts to discover our solutions for electric mobility, composite design, and high-performance vehicle applications.