Key points of the article

- Lubricants for the food industry are essential to ensure hygiene, safety and operational continuity in meat and poultry processing. In addition to lubricating, they must withstand mechanical stress, high temperatures and frequent washing.

- Relying on an experienced partner allows you to build a complete path fromanalysis of operating conditions to product selection to maintenance and staff training.

- Petro-Canada Lubricants solutions cover all stages of the food supply chain, from initial refrigeration to final packaging, ensuring high performance even in humid environments that undergo frequent sanitization.

- The PURITY FG range, thanks to SynFX technology, combines strength and durability of up to 4,000 hours with high regulatory compliance, offering asafe and high-performancealternative to conventional oils and greases.

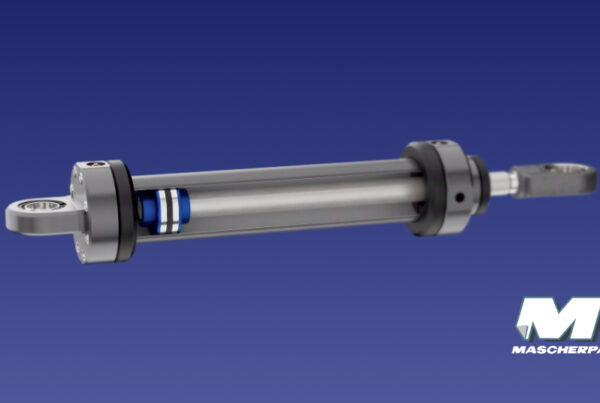

- At the IPACK-IMA exhibition, Mascherpa showed concrete examples of application, demonstrating how lubricant choice can improveproduction efficiency and reduce downtime costs.

In the food sector, and particularly in meat and poultry processing, food lubricants play a crucial role. They not only keep machinery in perfect working order, but also ensure food safety, reduce downtime and maintain the quality of the finished product.

I food machinery lubricants, such as those in the PURITY™ FG from Petro-Canada Lubricants, are designed to withstand extreme conditions and minimize any risk of accidental contamination. International certifications, high thermal stability, effective wear protection and runoff-resistant formulas make these food grade lubricants ideal for every stage of beef, pork and poultry meat.

From lubricant selection to maintenance

Rely on an experienced partner in lubrication for the food industry means being able to rely on a structured process that includes:

- Analysis of operating conditions and specific requirements (e.g., machines for meat processing, humid or cold environments).

- Selection of food-grade lubricating greases or most suitable oils, according to the production steps.

- Technical support and training for proper application.

- Maintenance planning and performance control over time.

Solutions for every step of the manufacturing process

At Mascherpa, through the Petro-Canada Lubrificants range of food lubricants, we make products for all the different stages of long and complicated processes, such as meat processing, whether beef, pork or poultry. In fact, the lubrication solutions we recommend are suitable for all stages of meat processing:

- Sanitation and refrigeration

- preparation, processing and cutting;

- marinating, mixing and frying;

- packaging and cold storage;

- poultry meat processing.

Sanitation and refrigeration

In the initial stages of the production process, lubricants for the food industry must withstand low temperatures, frequent washing and humid environments.

Component |

Recommended product |

Main benefit |

|---|---|---|

|

Bearings and rollers |

FG2 Synthetic, FG2 Heavy 220 |

High load capacity, long service life |

|

Protection from impact, corrosion and sludge formation |

||

|

Conveyor belts |

Resistance to runoff and continuous lubrication |

Blending, marinating, frying

Here high temperatures require stable fluids capable of protecting systems without degrading.

Application |

Ideal lubricant |

|---|---|

|

Plumbing systems |

FG AW, FG-X AW, FG Synthetic Fluid |

|

Diathermic plants |

FG Heat Transfer Fluid (HT1) |

|

Bearings |

Packaging and cold storage

In the last stages, lubricants for the food industry must be neutral, safe and suitable for incidental food contact.

Application |

Recommended product |

|---|---|

|

Compressors |

|

|

Belt reducers |

FG Synthetic EP, FG PAG Gear Fluid |

|

Technical sprays |

Poultry meat processing

Dedicated poultry lines also require advanced solutions capable of operating in humid environments with frequent washing.

Phase |

Suggested lubricant |

|---|---|

|

Unpacking and transportation |

|

|

Evisceration and cutting |

|

|

Breading and frying |

Choose PURITY™ FG: a long-term guarantee

SynFX™ technology integrated into many products PURITY™ FG enables performance similar to synthetics, with advantages on:

- Durability (up to 4,000 hours for compressors);

- Protection against rust, wear and tear, and corrosion;

- Resistance to temperature, water and oxidation;

- Compliance with NSF H1, 3H, HT1, ISO 21469, Halal and Kosher standards.

Switching to lubricants for the food industry high-quality lubricants means reducing maintenance costs, increasing efficiency and ensuring high hygienic and sanitary standards.

Mascherpa at IPACK-IMA: see solutions in action

During the IPACK-IMA trade show, at Mascherpa ‘s booth we showed up close the benefits of lubricants for food machinery certified, bringing real examples from the world of meat processing and food packaging.

Contact us for technical advice or view videos from the event-we will show you how the right lubricants can make a difference in your facility.