Key Points

- Thermal management is critical to ensuring the safety, durability, and performance of electric batteries in all sectors, from automotive to stationary storage.

- Thermal conductivity is the main parameter in design: it regulates heat transfer and affects the envelope, BMS and powertrain.

- Heat dissipation technologies , natural convection, forced-air cooling, and liquid cooling, allow for temperature and performance control.

- Thermally conductive pastes and resins such as Dowsil™ TC-4535, Dowsil™ TC-4025 and Sylgard™ 3002 UL94 V0 improve system efficiency and electronic protection.

- Tests show that the use of Sylgard™ materials prevents the propagation of thermal runaway, stopping the flame in less than 15 seconds.

- Mascherpa ‘s collaboration with the PoliMi Motorcycle Factory confirms the importance of thermal management even in the design of electric motorcycle prototypes.

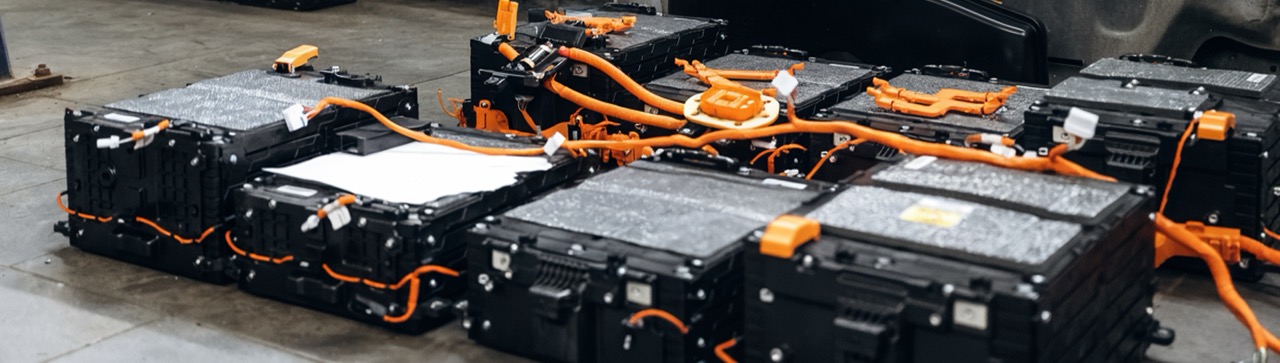

The battery market has existed for many years and is divided into different applications:

- power tools;

- Stationary accumulators;

- heavy machinery;

- electric vehicles.

Depending on the development goals, thermal management takes on different roles, in fact it can cover:

- the internal elements;

- the battery casings;

- integration to the frame;

- impact resistance;

- The increased durability of the cells;

- The overall security of the system.

Each goal brings with it specific design challenges. In addition to the well-known “range anxiety,” the life cycle and performance of electric batteries depend on parameters such as cooling, fast charging, and cell aging.

The meeting point in all these cases is battery thermal management (thermal management), a key element for performance, safety, and durability.

Index

- Thermal conductivity in thermal management systems

- Impact of temperature on performance

- Heat dissipation technologies

- Thermal conductive pastes for thermal management

- Thermally conductive resins and potting

- Thermal runaway: the risk to be controlled

- Testing the efficiency of SylgardTM products.

- Collaboration with PoliMi Motorcycle Factory

- The importance of thermal management

Thermal conductivity in thermal management systems

One of the key parameters in the design of thermal management battery systems is thermal conductivity, which is the amount of heat transferred between different materials, measured in watts.

The heat transfer coefficient is measured parametrically in Watt meter kelvin (W/m-K) and is the parameter that influences every aspect of a battery design : from the casing to the BMS (Battery Management System), from the powertrain to the overall design of the battery pack.

During charging and discharging, heat spreads within the system and must be properly managed to avoid overheating the battery.

This point is particularly critical when aiming for ultrafast recharging or high performance, as heat generation increases significantly.

Impact of temperature on performance

The performance of e-mobility batteries is closely related to operating conditions.

- At low temperatures, cells fail to charge up to100%.

- At high temperatures (above 100 °C), internal materials begin to degrade, reducing the capacity and service life of the battery.

Temperature control then becomes an essential element of thermal management: keeping batteries in the right thermal range means ensuring consistent performance and safety over time.

Heat dissipation technologies

For proper heat dissipation, there are three main engineering approaches, chosen according to the amount of heat energy to be dissipated:

- Natural Convention

- Forced-air cooling

- Liquid cooling

Natural convection

Natural convection is used when the heat to be dissipated is very low; this technology uses the spontaneous movement of air or other fluids to distribute temperature.

Forced-air cooling

When the heat to be dissipated is less than about 800 W, forced-air cooling is used, in which fans or guided air flows increase the efficiency of heat transfer.

In these systems, heat passes from the coil to an evaporator or cooling plate (cooling plate).

Liquid Cooling

For values above 1 kW, liquid cooling, similar to an automotive radiator, is used.

The heat transfer fluid flows through channels or plates in contact with the battery module, ensuring high thermal conductivity andefficient operation even under extreme load conditions.

Thermal conductive pastes for thermal management

Whether it is a cooling plate or a heat exchanger, the addition of thermally conductive pastes dedicated enables improved heat transfer and reduced thermal contact resistance between surfaces.

Two significant examples of products used in the e-mobility sector are:

- Dowsil™ TC-4535: conductive gap filler with high efficiency;

- Dowsil™ TC-4025: dispensable thermal pad ideal for high-density applications.

These materials represent reliable and proven solutions in the electronic protection and thermal management of batteries.

Thermally conductive resins and potting

Another highly effective technology is potting, or dipping the cells in a thermally conductive resin.

This technique makes it possible to equalize the internal temperature of the module, improve electrical insulation, and reduce the risk of battery overheating even under high thermal stress conditions.

A concrete example is Sylgard™ 3002, a two-component silicone resin with UL94 V0 rating. Due to these properties, Sylgard™ 3002 resin finds application in storage modules, thermal management battery systems, and all solutions where electronic protection and fire resistance are critical requirements.

What the abbreviation UL94 V0 means

The acronym UL94 V0 identifies the highest self-extinguishing class under UL 94, the international standard for evaluating the flamebehavior of plastic materials.

A UL94 V0-certified material is capable of autonomously stopping combustion within 10 seconds of ignition and of not generating glowing droplets-essential characteristics for ensuring the safety of electric battery systems and other components in the e-mobility industry.

Thermal runaway: the risk to be controlled

The phenomenon of thermal runaway is a major critical issue in the design of electric vehicle batteries.

Although it becomes uncontrollable around 300 °C, the degradation process of the components can begin as early as around 100 °C, triggering an exothermic reaction and the so-called venting phase , in which toxicand flammable gasespropagate inside the damaged cell.

When the reaction becomes irreversible, temperatures can reach between 700 °C and 1000 °C, with devastating consequences for the entire system.

Currently, the best-known relevant standard is UN H GTR 2, which establishes a minimum interval of 5 minutes between the thermal runaway warning and the safe escape of passengers from the passenger compartment.

Testing the efficiency of Sylgard™ products.

A test conducted by Dow in collaboration with Mascherpa concretely demonstrated the effectiveness of electronic protection solutions based on silicone materials.

In a small battery casing subjected to thermal runaway, the standard version showed flame propagation, while the same configuration impregnated with Sylgard™ prevented thermal spread.

The flame stopped in less than 15 seconds, far exceeding the requirements of UN H GTR 2.

Next collaboration with PoliMi Motorcycle Factory

The topic of thermal management is also central to the collaboration between Mascherpa and the PoliMi Motorcycle Factory, the Politecnico di Milano team that designs and builds internal combustion and electric racing prototypes.

In the construction of electric prototypes , battery thermal management plays a crucial role in ensuring safety, consistent performance and reliability during competition.

Thanks to the technical support and materials provided by Mascherpa, including thermal conductive pastes, silicone resins and electronic protection solutions , the projects of the PoliMi Motorcycle Factory team represent a concrete example of how EV thermal management technologies can also be successfully applied in university motorsport.

The importance of thermal management

In the field of electric batteries and e-mobility, thermal management is an essential pillar for safety and reliability.

Each energy system requires a thermal management model calibrated to its specific needs: materials, power density, module architecture and regulatory requirements.

Today’s available solutions, such as heat-conductive pastes, heat-conductive resins, and potting, make it possible to optimize heat dissipation, reduce battery overheating, and improve safety against thermal runaway.

All these technologies are part of Mascherpa ‘s portfolio and supported by technical programs developed in collaboration with Dow, DuPont, and Huntsman.

For more information regarding thermal management and electronic battery protection, contact our Mascherpa experts or download our technical guide dedicated.

Also discover the Mascherpa Expert to access technical content, tips and best practices.