Key Points

- Molykote® PFAS-free industrial lubricants were created as a practical response to new sustainability and safety requirements.

- These solutions eliminate the use of persistent fluorinated substances, reducing environmental impact, without compromising wear resistance or thermal stability.

- The products in the Molykote® PFAS free range represent concrete examples of innovation applied to industrial lubrication, covering a broad spectrum of needs, from mechanical systems to food processing contexts.

- Adopting Molykote® PFAS-free lubricants means anticipating regulatory changes, improving the corporate responsibility profile and contributing to a cleaner and safer industrial transition.

As environmental and health regulations evolve, the industrial sector is driven to deepen its practices, particularly in the field of lubrication. The PFAS-free industrial lubricants in the Molykote® reflect this shift toward more sustainable solutions.

Developed by DuPont™, Molykote® DX(S), Molykote® P-40(S) e Molykote® G-4500 FMS are examples of this commitment.

These technically advanced products enable industrial operators to maintain high performance standards while aligning with growing environmental safety regulations.

Index

- What PFAS free means

- Technical presentation of PFAS free Molykote® products.

- Technical advantages of PFAS-free lubricants in the Molykote® range.

- Key markets and applications of PFAS-free lubricants

- Benefits of PFAS-free lubricants

- Comparison of conventional products and PFAS-free lubricants

- FAQ

- Choose PFAS-free lubricants from the Molykote® range.

What PFAS free means

PFASs ( per- and polyfluoroalkyl substances ) are a broad class of synthetic fluorinated chemicals known for their resistance to heat, water and chemicals. Widely used for decades in various industries, PFASs are now under scrutiny because of their persistence in the environment and their tendency to bioaccumulate.

A PFAS-free product is formulated without the addition of these substances.

Technical presentation of PFAS free Molykote® products.

| Product | Product Type / Appearance | Range of temperature | Components main | Applications main |

| Molykote® DX(S) | White grease | from -25 °C a +125 °C | Mineral oil, lithium soap, solid lubricants | Threaded assemblies, guides, hinges |

| Molykote® P-40(S) | Pasta for

assemblies |

from -40 °C a +230 °C (paste) / +1200°C (dry) | PAO oil, solid lubricants, corrosion inhibitor | Screw joints, brake systems, marine use |

| Molykote® G-4500 FMS | Grease multipurpose | from -40 °C a +150 °C | Synthetic base, free of PFAS and heavy metals | Food and pharmaceutical industries, clean environments |

Technical advantages of PFAS-free lubricants in the Molykote® range.

Molykote® DX(S)

Molykote® DX(S) excels in low-speed lubrication at high loads.

- Excellent resistance to runoff.

- Protects against corrosion and seizure.

- Clean, non-staining formulation.

- Long-lasting lubrication in harsh environments.

- Easy application with brush, trowel, cloth or automated systems.

Molykote® P-40(S)

Molykote® P-40(S) is a high-performance assembly and lubrication paste.

- Exceptional wear resistance in harsh environments.

- Lubrication up to 1200 °C in dry conditions.

- Without metals, it minimizes the risk of contamination.

- Strong adhesion for long-term assembly applications.

Molykote® G-4500 FMS

Molykote® G-4500 FMS is a PFAS- free lubricant and complies with food regulations:

- Excellent thermal and chemical stability.

- It significantly reduces maintenance requirements.

- Versatile, suitable for sensitive industrial environments.

Key markets and applications of PFAS-free lubricants

- Food industry and pharmaceuticals-where sustainability and cleanliness are key.

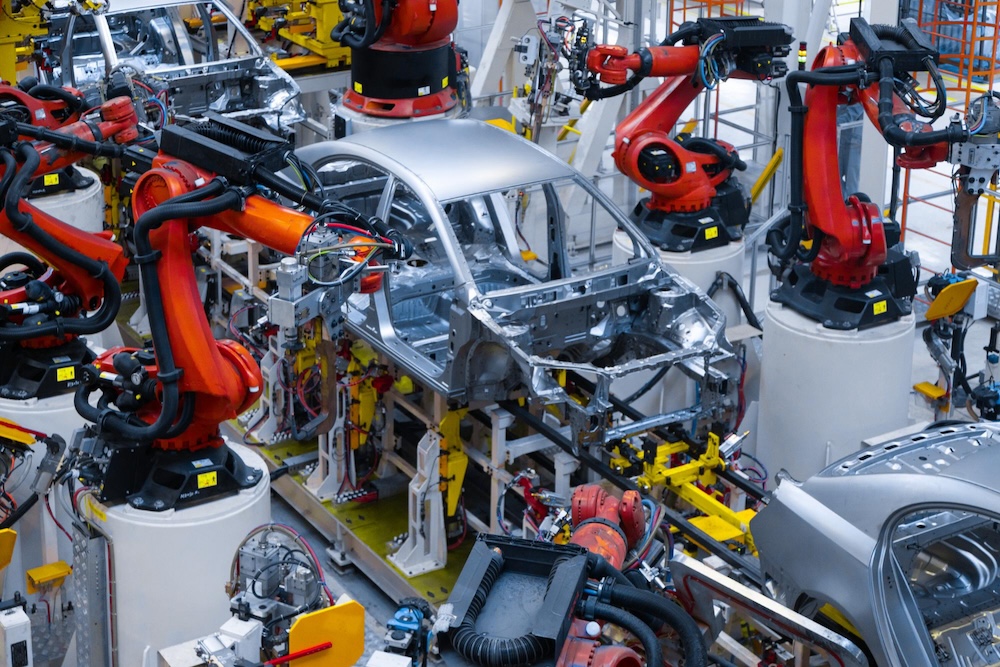

- Automotive e transportation: for systems exposed to high loads or temperatures.

- Electronics and precision equipment: clean lubrication without residue.

- Marina e industry heavy: corrosion resistance under extreme loads.

Benefits of PFAS-free lubricants

PFAS-free lubricants with their properties provide numerous environmental benefits, including:

- No long-term PFAS-related pollution,

- Reduction of bioaccumulation in ecosystems,

- Lower impact on natural resources.

FAQ on PFAS free lubricants

Are PFAS-free lubricants as effective as conventional products?

Yes, PFAS-free Molykote® lubricants are designed to match conventional products in terms of wear resistance, thermal stability, longevity, and performance at both high and low temperatures.

Are PFAS-free lubricants in compliance with HSE regulations?

Absolutely. Molykote® PFAS-free lubricants are formulated to meet stringent health, safety and environmental (HSE) standards.

Does switching to PFAS-free lubricants require a thorough cleaning?

Yes. For optimal performance and to eliminate residual PFAS contamination, it is best to clean existing deposits before applying a new PFAS-free lubricant. This is considered the best practice for a clean transition.

Choose PFAS-free lubricants from the Molykote® range.

Molykote® PFAS-free lubricants perfectly demonstrate the industry’s ability to reconcile technical performance and environmental protection. Their adoption enables companies to anticipate regulatory changes, protect equipment and minimize their ecological impact. For more information on individual products in the Molykote® PFAS free range, contact our Mascherpa experts.