Key points of the article

- Krytox™ lubricants ensure operational reliability even in the most extreme conditions of the aerospace industry, withstanding temperatures from -73 °C to +399 °C, radiation, high vacuum, and aggressive chemical agents.

- The range includes high-performance greases and oils, MIL-SPEC certified, designed for critical applications such as oxygen valves, space suit joints, and avionic actuators.

- Krytox™ is used for lifetime lubrication of components such as bearings, actuators, seals, and optical systems, minimizing maintenance interventions in inaccessible environments.

- Mascherpa offers comprehensive technical support for the integration of Krytox™ lubricants, with consulting, training, certified documentation, and a dedicated warehouse for rapid supplies.

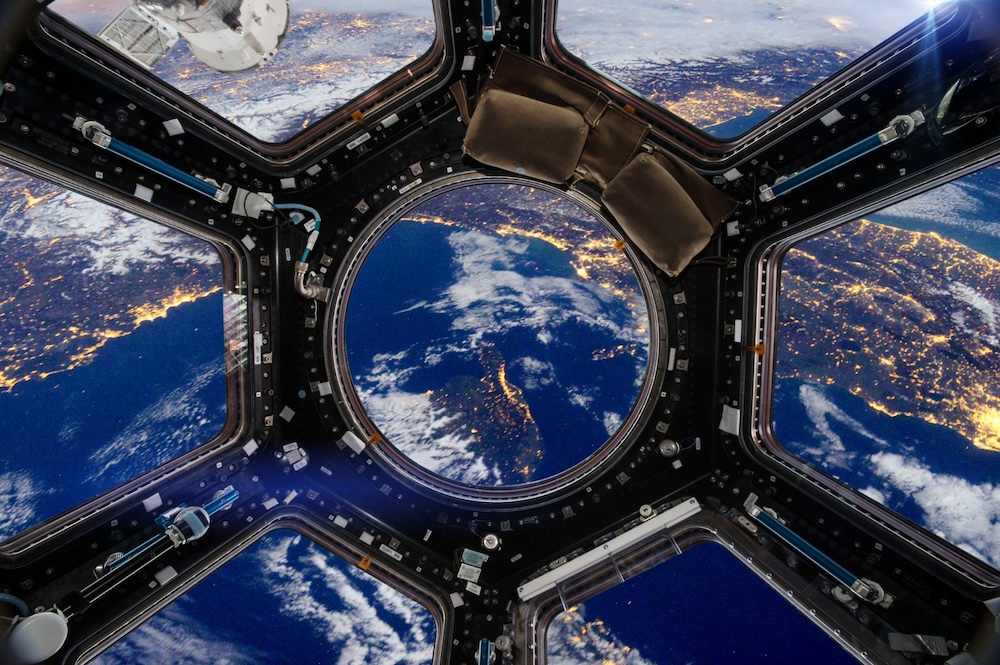

In the aerospace industry, reliability is not just a feature: it’s an essential condition. Every component, every connection, and every lubricant must withstand extreme environmental conditions, high pressures, and severe thermal fluctuations.

In this context, Krytox™ lubricants represent a guarantee of performance and safety. Designed in the 1960s for the aerospace industry, they have evolved into a complete range of high-performance greases and oils designed to meet the most stringent standards of aviation and space exploration, now finding application also in the aerospace and defense sectors.

Designed for Space, Certified for Safety

Activities in the space sector are rapidly expanding. Beyond institutional missions, entities like SpaceX, Virgin Galactic, and Blue Origin are making commercial flights routine. Making all this possible are advanced technologies that require lubricated components capable of functioning in extreme conditions, without compromises.

Krytox™ lubricants, based on perfluoropolyether (PFPE), have been tested in dozens of orbital, suborbital, and deep space missions, demonstrating:

-

Thermal stability from -73 °C to +399 °C

-

Resistance to radiation and chemical degradation

-

Low evaporation in vacuum (essential beyond Earth’s atmosphere)

-

Chemical inertness with fuels, oxidizers, and aggressive fluids

-

Compatibility with metals, elastomers, paints, plastics

-

No flammability, toxicity, or hazardous evaporation

Thanks to these characteristics, Krytox™ Aerospace is also used in sensitive applications such as oxygen valves, avionic systems, and space suit joints.

Where are Krytox™ Lubricants Used?

Krytox™ is present in numerous applications within the aerospace industry:

Mechanical components and actuators

-

High-speed bearings for turbines and engines

-

Ball screws, lead screws, and linear actuators

-

Gearboxes and gear motors in vacuum environments

-

Anti-vibration supports and motor couplings

Sealing systems and fluids

-

Fuel and oxidizer valves for liquid propellants

-

Static or dynamic seals and gaskets in cryogenic environments

-

Oxygen management systems compliant with NASA regulations

-

Seals for pressurized suits and hydraulic systems

Electronics and sensors

-

Gyroscopes, gimbals, and finely tuned actuators

-

Insulated electrical connectors lubricated with non-conductive grease

-

IR sensors and optical systems with low-migration lubricants

Krytox™ is also appreciated for the lifetime lubrication of components, minimizing maintenance operations and extending service intervals, a fundamental advantage in applications where relubrication is impossible.

Krytox™ Greases: Characteristics and Specifications

The range of Krytox™ greases for the aerospace sector includes MIL-SPEC certified references, versions for extreme pressures, and rust-inhibited grades.

| Product Name | Viscosity at 38 °C (100 °F) | Viscosity at 99 °C (210 °F) | Estimated Useful Temperature Range °C (°F) | Mil/Spec | Features |

|---|---|---|---|---|---|

| Krytox™ 240AZ GD1 Grease | 24.7 | 4.2 | -57 to 149 (-70 to 300) | Type I | |

| Krytox™ 240AA Grease | 35 | 5.4 | -51 to 177 (-60 to 350) | n/a | |

| Krytox™ 240AB Grease | 86 | 10.5 | -40 to 232 (-40 to 450) | Type II | |

| Krytox™ 240AC Grease | 270 | 26 | -34 to 288 (-30 to 550) | Type III | |

| Krytox™ 240AD Grease | 502 | 44 | -29 to 316 (-20 to 550+) | n/a | |

| Krytox™ 250AC Grease | 270 | 26 | -34 to 288 (-30 to 550) | n/a | Designed for extreme pressure |

| Krytox™ 250AD Grease | 502 | 44 | -29 to 316 (-20 to 550+) | n/a | Designed for extreme pressure |

| Krytox™ 250AZ Grease | 24.7 | 4.2 | -57 to 149 (-70 to 300) | n/a | Designed for extreme pressure |

| Krytox™ 283AA Grease | 35 | 5.4 | -51 to 177 (-60 to 350) | n/a | Rust inhibited grade |

| Krytox™ 283AB Grease | 86 | 10.5 | -40 to 232 (-40 to 450) | n/a | Rust inhibited grade |

| Krytox™ 283AC Grease | 270 | 26 | -34 to 288 (-30 to 550) | n/a | Rust inhibited grade |

| Krytox™ 283AD Grease | 502 | 44 | -29 to 316 (-20 to 550+) | n/a | Rust inhibited grade |

| Krytox™ FPG-028 Grease | 50.5 | — | -73 to 204 (-99 to 399) | Type IV | |

| Krytox™ FPG-182 Grease | 138 | 37.6 | -80 to 210 (-112 to 410) | n/a | |

| Kryotx™ AGL 683 Grease | 32 | — | -60 to 120 (-76 to 248) | n/a | Designed for gearboxes |

| Kryotx™ AGL 829 Grease | 49 | 7.2 | -60 to 120 (-76 to 248) | n/a | Designed for gearboxes |

Krytox™ Oils: Fluid Performance for Extreme Environments

When lubrication requires greater fluidity, cooling, or precise viscosity behavior, Krytox™ oils come into play, used in pumps, turbines, dynamic seals, and rotating instruments.

| Product Name | Average Molecular Weight | Estimated Useful Temperature Range °C (°F) | Viscosity at 40 °C (104 °F) | Viscosity at 100 °C (212 °F) |

|---|---|---|---|---|

| Krytox™ 143AZ Oil | 2060 | -57 to 149 (-70 to 300) | 22.8 | 4.1 |

| Krytox™ 143AB Oil | 3800 | -40 to 232 (-40 to 450) | 78 | 10.2 |

| Krytox™ 143AC Oil | 5940 | -34 to 288 (-30 to 550) | 243 | 25.4 |

| Krytox™ 143AD Oil | 7480 | -29 to 315 (-20 to 600) | 450 | 42.4 |

Why Choose Mascherpa for Aerospace Applications?

Mascherpa supports the aerospace sector in Italy by providing comprehensive assistance in the selection, validation, and integration of Krytox™ lubricants into their systems.

In addition to simple supply, we offer:

-

Technical consultancy for identifying the most suitable product

-

Support for documentation and certification (MIL-SPEC, NSF H1)

-

Technical training and assistance in application testing

-

Dedicated warehouse for rapid supplies even on critical projects

Conclusion

In the aerospace sector, where every detail is vital and every mistake can have critical consequences, using a certified grease or lubricant represents a strategic choice for those working in design, testing, production, and maintenance.

Krytox™ aerospace lubricants offer stability, high performance, and a long operational life even in the most extreme conditions of the known universe.

Contact the Mascherpa experts to receive personalized advice and discover which Krytox™ solution best suits your design or application needs.