Key Points

- The design of the Alba skiff started from defining the objectives and constraints, with a clear focus on sustainability and real nautical application.

- The choice of reinforcement materials, such as Saertex flax fiber combined with glass fiber and carbon, guided the construction process from the early stages.

- The sandwich structure with 3D core in recycled PET contributed to the cohesion of the laminate and the reliability of the hull over time.

- The infusion process integrated recycled consumable materials, extending sustainability to the operational construction phases as well.

- The bio-based epoxy resin Huntsman LY 5052 MBC completed a coherent path that combines materials, process and final result.

The Alba skiff was born as a university project of the Revel Sailing Team, developed with the University of Genoa and the University Campus of La Spezia.

Within the Mascherpa NEXT program, Mascherpa supported the team in their choices regarding composite materials, with a clear role: to support the decision-making process without replacing the students’ design work.

This article tells how to build a sustainable skiff starting from the choices, following the actual order in which materials and process are addressed during construction.

Before materials, define the challenge

Every composite project starts with a simple but decisive question: what type of boat do you want to build and with what constraints.

In the case of the Alba skiff, the objective was clear from the beginning: to create a skiff that would meet sustainability parameters, without compromising construction and practical application in the nautical field. This immediately oriented the discussion between Mascherpa and the Revel Sailing Team.

Even before talking about resin or sandwich structure, it was necessary to identify materials compatible with the infusion process, workable effectively and consistent with the sustainable approach of the project.

When reinforcement guides the process

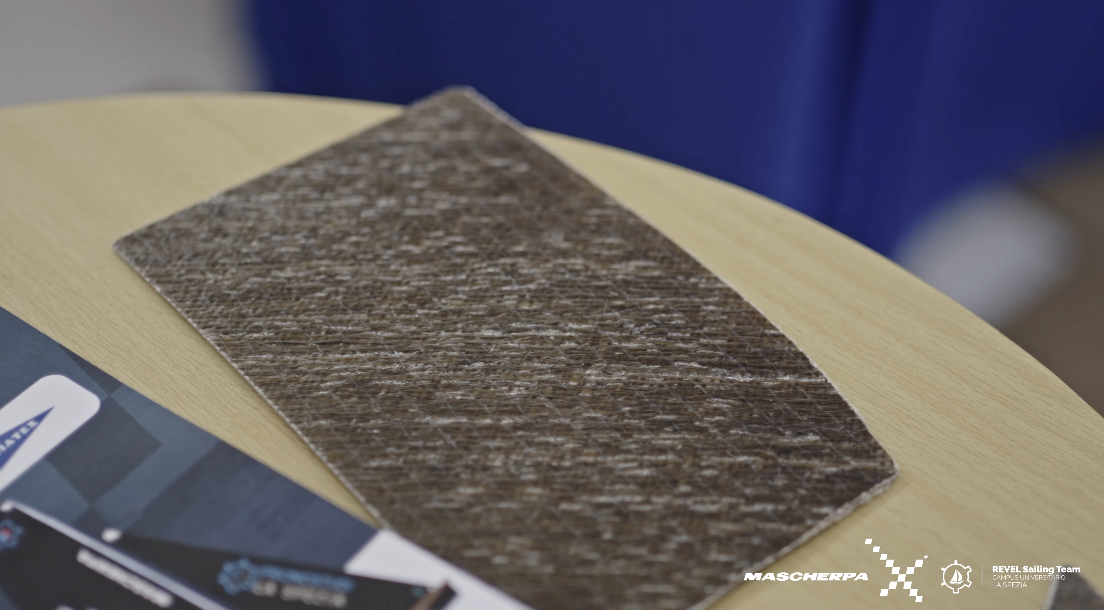

The first concrete choice concerned the reinforcement materials.

For the Alba skiff, Mascherpa proposed the use of flax fiber Saertex, selected for two fundamental characteristics that emerged during the technical discussion:

- drapability;

- wettability.

These aspects are central in the layup and infusion phases, because they directly affect the quality of the laminate and the ease of processing. The flax fiber was used for part of the hull and was laminated exactly like other composite reinforcements.

To support the flax fiber, glass fiber and Saertex carbon fiber were also used in the layup, according to the construction requirements defined by the project.

Here the material is a practical response to a real construction need.

The importance of material cohesion, beyond thickness

Once the layup was defined, the next step concerned the sandwich structure of the hull.

For the Alba skiff, 3D core was used, a material in recycled and recyclable PET, chosen for its behavior during processing.

The 3D core presents characteristics that directly affect the final quality of the laminate:

- ability to adapt to hull curvatures.

- favorable behavior in the resin flow during infusion.

Its hexagonal processing allows for an extremely cohesive sandwich between outer skin and inner skin, helping to reduce the risk of delamination. In this case, the core material is not a simple structural element, but an active part of the reliability of the composite system.

The infusion process and the use of recycled materials

The Alba skiff was made through an infusion process, and this extended the theme of sustainability to the operational phases as well.

During construction, consumable materials from recycling were used, particularly injectors derived from wood recycling and materials obtained from grape waste.

These elements do not remain in the hull, but are part of the production process and contribute to making the adopted approach consistent.

In a project like the Alba skiff, sustainability concerns not only what you see, but also how you reach the final result.

Closing the circle: epoxy resin

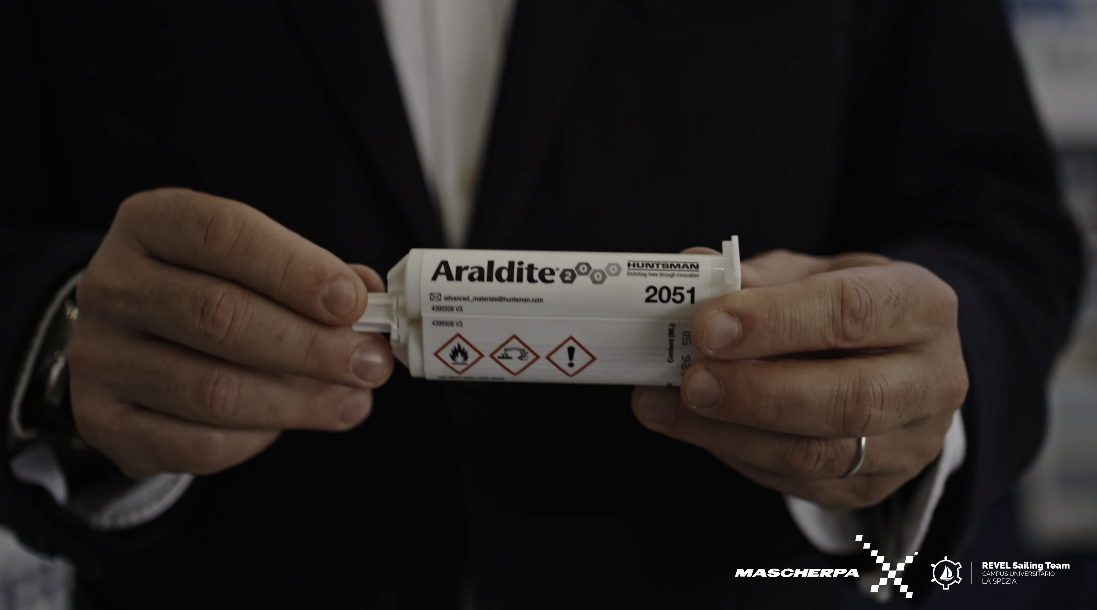

The last step concerned the choice of epoxy resin for composites fundamental in the infusion process.

The resin Huntsman LY 5052 MBC was used, supplied by Mascherpa, characterized by the fact that most of its ingredients come from biomass.

This choice allowed the Alba skiff to be awarded RedCert² certification, as a bio resin, completing a coherent path that starts from the reinforcement and reaches the matrix.

From technical comparison to final result

The work on the Alba skiff fits fully into the Mascherpa NEXT philosophy: supporting university teams through technical discussion on materials and processes, leaving students in control of the project.

The dialogue with the Revel Sailing Team, composed of extremely well-prepared students, made it possible to discuss concrete technical solutions and accompany the team in choices related to composite materials, from layup to infusion.

The path of the Alba skiff, which led the project to be presented in contexts such as the Genoa Boat Show, demonstrates how structured work on decisions can transform into a real boat, built step by step.

For more information regarding the collaboration between Mascherpa and the Revel Sailing Team, visit the dedicated Mascherpa Next page and watch our videos.