CASE STUDY:

Molykote 111 in water desalination processes.

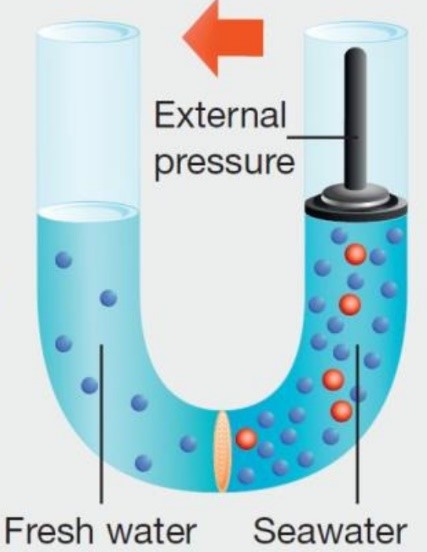

DESALINATING WATER THROUGH REVERSE OSMOSIS

To desalinate water, a flow through a membrane must be created; this flow causes the water to leave the salty part, flowing into the unsalted part. For this to happen, pressure must be generated on the water column from the salt side, first to remove the natural osmotic pressure and secondly to generate additional force on the water column to push water through the membrane.

Reverse osmosis can be used for the separation of water from all substances dissolved in it, to produce water that is essentially free of salts.

CUSTOMER’S TECHNICAL REQUESTS

During assembly of the diaphragm series and the necessary o-ring, the customer needs a product that performs the dual function of assembly lubricant and sealant against high-pressure water

- Load: 1,200 psi (82 Atm)

- Environment: seawater

- Temperature: ambient

Previously used lubricant: Lithium-based grease with additives.

MASCHERPA MOLYKOTE SOLUTION

The customer was looking for a product that was approved for contact with WRAS drinking water and managed to have the desired sealing effect; the competitor’s lubricant does not meet these needs.

Mascherpa and Molykote technicians have identified the

Molykote 111 Compound

the perfect grease for this application.