Freeze maintenance costs with REFLO

The food processing and refrigerated storage sectors pose unique challenges for lubricants. Continuity of performance is of paramount importance for storing your products efficiently in the warehouse. As demands for energy efficiency improvement and cost reduction increase, maintenance managers face challenges that only high-performance lubricants can help overcome.

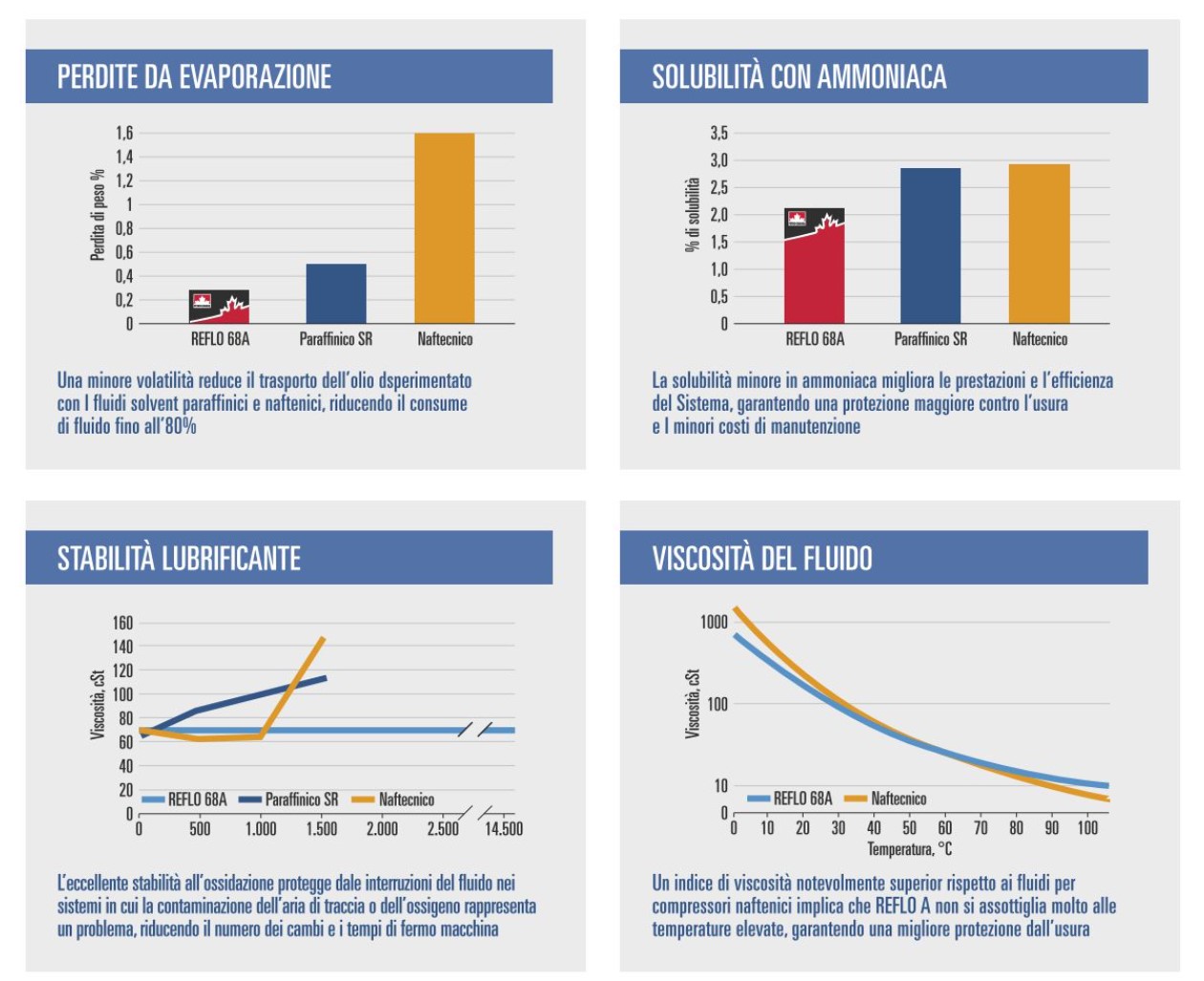

Our complete line of REFLO compressor fluids, together with proper maintenance, can reduce fluid consumption, zero downtime, protect equipment and save money. REFLO has facilitated significant reductions in lubrication costs for companies worldwide: in some cases, up to 80 percent.

REFLO 68A

Formulated to provide reliable, long-term performance with significant savings in operating costs.

- Lower oil volatility reduces fluid consumption and maintenance costs.

- Lower ammonia solubility allows for improved refrigeration efficiency.

- Strong thermal and oxidation stability increases fluid life by reducing maintenance costs and downtime.

- REFLO 68A is approved or meets the requirements of most original compressor manufacturers.

REFLO MEETS THE REQUIREMENTS OF THE FOLLOWING MANUFACTURERS

- Bitzer

- CKD COMPRESSORS

- Frick/York

- Frigoscandia

- Gram

- Grease

- Howden

- Huppmann GMBH

- J&E Hall

- Mycom

- Sabroe

- Vilter

CASE HISTORY: REFLO 68A PETRO-CANADA

The Claus Sørensen Group manages the cold chain at Denmark’s major fishing ports and is the largest supplier of ice to the world’s fishing industry. They have 11 facilities located with a total of 692,000 cubic meters of cold storage capacity. The company, which employs 1,000 people, has more than 80 years of experience in freezing and food preservation.

THE CHALLENGE.

The maintenance of a cold storage room is a complex activity. Compressors used in cooling systems are critical to successful operations and must be constantly maintained at maximum efficiency to keep operating costs in line.

“Our freezing plants have stringent requirements for the compressor oil we use,”

, explains Michael Glering, plant technical manager at the Claus Sørensen plant in Vejle.

“We operate at temperatures as low as -20°C, so we need a compressor oil that meets these requirements.”

When Claus Sørensen purchased several new Grasso refrigeration compressors for their plant, they required a compressor fluid that could:

- Manage the frigid temperatures of their facilities

- Providing equipment protection

- Offer the potential to reduce oil consumption and save costs

THE SOLUTION.

Claus Sørensen recently overhauled one of his Grasso compressors. The machine had been in operation since 2003 and operated for a total of 36,000 hours with REFLO 68A. What their technicians found inside was not what they expected. “We were very surprised when we saw the results.”, says Glering. “The interior parts looked as if they had just been installed“. Even after eight years of operation, the compressor showed no signs of coke formation and, thanks to REFLO A’s excellent protection, wear and tear was so minimal that the internal components were still very close to the tolerance of brand-new parts. Normally, the lubricating oil used by the refrigeration circuit is discarded, but after filtering, REFLO 68A was almost the same as the day it was poured into the system. Since switching to REFLO A, Claus Sørensen has not only experienced the performance benefits, but is also discovering how REFLO A can improve profits. “With REFLO 68A, we plan to halve the total lubricating oil consumption for our compressors. When you consider the 27 Sabroe and Grasso piston compressors we have here in Vejle and the larger number of compressors we operate nationwide, the cost savings can really add up. “