Key points of the article

- DOWSIL™ silicone conformal coatings provide reliable and long-lasting protection for PCBs even under extreme environmental and mechanical stresses.

- The choice of silicone conformal coating is based on viscosities, curing profiles and hardnesses to suit specific project and application requirements.

- Solvent-free formulations help simplify production, reduce operating costs and comply with environmental regulations.

- Mascherpa supports designers and engineers in choosing the most suitable coating, providing technical advice and high-performance products for advanced applications.

In theElectronics industry, reliable protection of PCBs requires materials that can respond to extreme mechanical, thermal and environmental stresses. DOWSIL™ silicone conformal coatings represent an advanced, flexible and sustainable technical answer to the needs of designers, engineers and process managers operating in critical environments. In this guide we look in detail at the characteristics of Dow conformal coatings and the main variables to consider in their selection.

Why evaluate DOWSIL™ silicone conformal coatings.

When it comes to reliable and durable electronic protection, choosing the right materials makes all the difference. DOWSIL™ silicone conformal coatings represent one of the most advanced standards in the industry today.

Dow Performance Silicones has been a global benchmark in silicone technology for more than 70 years. This expertise translates into stable, high-performance and safe products designed to ensure operational continuity even under the most extreme conditions.

Silicone chemistry offers concrete design advantages: greater design freedom, broad viscosity and curing range, and application versatility that also meets the needs of sustainability and environmental regulation. But let’s look at their main features together:

Increased thermal stability

Silicones maintain reliable performance between -45°C and +150°C, well beyond the limits of organic coatings. Many silicones can withstand even short exposures up to 250°C.

Stress release

Silicone conformal coatings offer an extremely wide range of durometers, including very low moduli. This ensures better stress release on delicate electronic components during thermal cycling.

Fast and solvent-free care

Most silicones-including UV-cured ones-are solvent-free, making them ideal in regulatory settings that impose stringent handling and safety requirements.

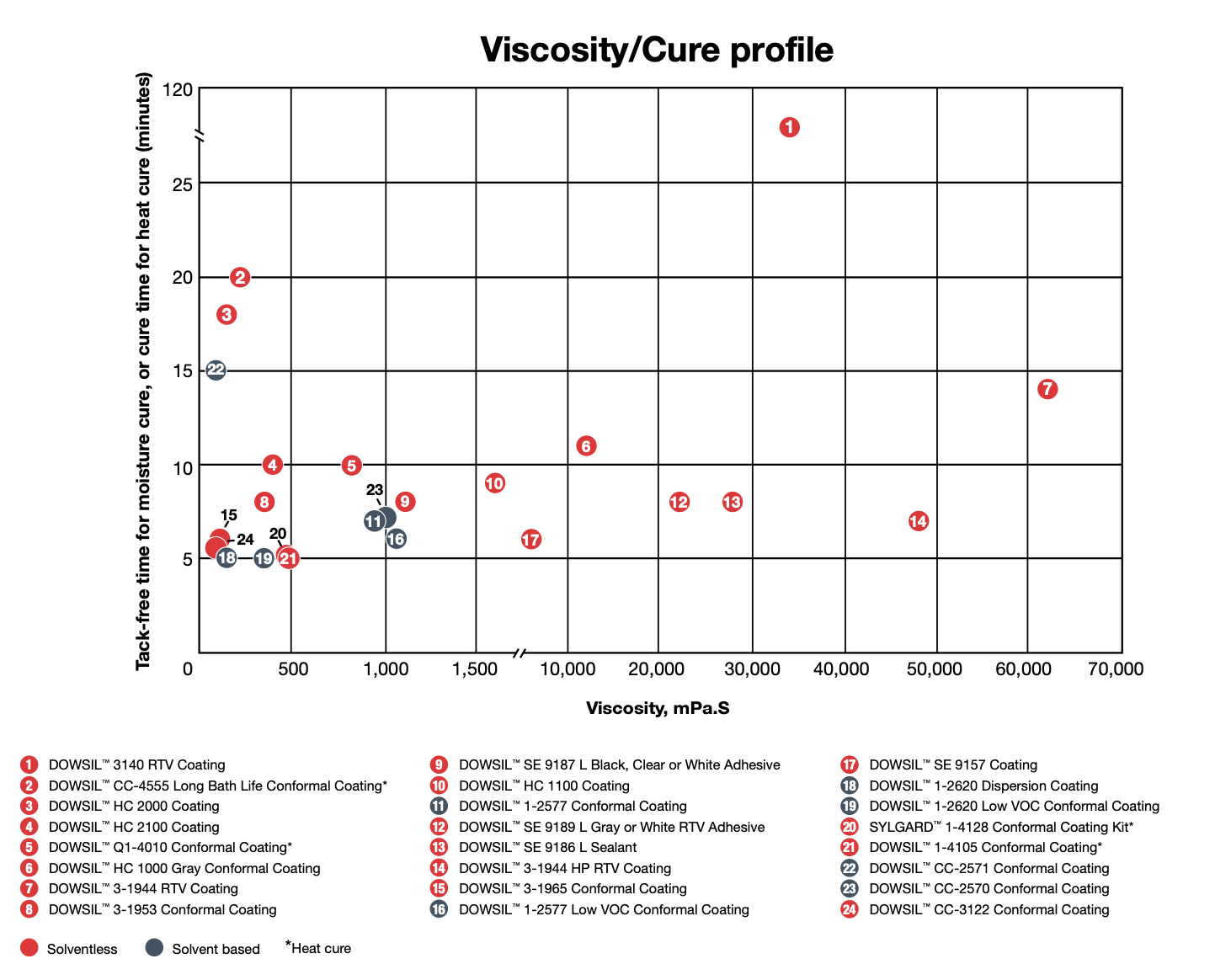

To identify the right silicone conformal coating for your application, it is critical to evaluate three key parameters: viscosity, cure profile and hardness.

Each characteristic has a direct impact on the final performance of the coating and compatibility with geometries, processes and production volumes. Let’s now look at them in detail.

Choose the right viscosity

DOWSIL™ conformal coatings are available in a wide range of viscosities to meet all specific process and application requirements.

Low viscosity for high-speed productions

They support manual or automated spraying, flow coating or jetting. Ideal for applications where coating must flow through vias or under chips.

High viscosity for more control

They offer increasing control over speed and sliding distance, preventing spreading into impermissible areas. They allow thicker applications in a single pass and, in some cases, stable coatings even on vertical surfaces.

Products such as the DOWSIL™ 3-1944 RTV Coating and the DOWSIL™ 3140 RTV Coating are examples of high-viscosity silicones used to provide thick and stable coatings.

Choose the appropriate curing profile

DOWSIL™ silicone conformal coatings offer versatile curing profiles to choose the ideal solution based on production line configuration, volume and product application.

Rapid curing in humid environments

These coatings cure rapidly at room temperature, providing a “dispense and forget”, tack-free solution in less than ten minutes, ideal for high volume production. In addition, productivity can be further increased by heat or UV light.

Polymerization with extended processing time

Silicone coatings in this category also cure at room temperature, but allow conformal silicone coating to spread longer on large PCBs or panels. They are also best suited for applications that require a thicker coating.

Thermal polymerization

Sometimes referred to as “command-cured,” they allow complete cure in less than five minutes, reducing thermal stress on components. Conformal coatings in this category are suitable when processing operations require fast full cure and low stress on electronic boards during thermal cycling.

Hardness of Conformal Silicone Coatings

Due to their low elastic modulus, silicones offer superior flexibility compared to organic coatings, minimizing stress on wires and welded joints. Also available in high abrasion resistance versions, they are ideal when additional mechanical protection is required without sacrificing thermal stability and durability.

Maximum stress release (<15 Shore A)

Softer silicone coatings, such as DOWSIL™ 3-1944 HP RTV Co ating, are suitable for very sensitive components that are more susceptible to thermal cycling, such as thin wires.

Stress release (15 – 40 Shore A)

These conformal coatings are an ideal alternative to brittle organic coatings, plus they offer an ideal compromise between stress reduction and protection from harsh environments (moisture, dust, vibration, impact).

Abrasion resistance (40 Shore A – 25 Shore D)

coatings in this category cure to form tough, durable coatings similar to acrylics, but with greater flexibility and superior performance at extreme temperatures.

Why choose solvent-free silicones

Although solvent-based versions are available, most DOWSIL™ silicone conformal coating sprays are formulated without solvents, a feature that is increasingly in demand industrially.

Dow offers solvent-based elastoplastic coatings that can mimic the hardness of acrylic coatings, but it is in the solventless range that today’s most advanced and strategic solutions for modern production lines are concentrated. One example is the DOWSIL™ 1-2577 Conformal Coating which is among the most popular solventless formulations for PCB protection.

Choosing solvent-free silicone conformal coating means significantly reducing operational complexities, process time, and costs associated with handling, safety, and environmental compliance. In fact, the use of solvent-based products can require:

- Additional safety protocols for worker protection

- Special equipment for ventilation and smoke management

- Precautions in handling flammable substances

- Adapting to increasingly stringent environmental regulations

Opting for solvent-free silicone coatings is not only an easier and more sustainable choice-it is also a competitive advantage for those seeking production efficiency, application reliability and regulatory continuity.

Conclusion

When selecting a silicone conformal coating, every variable-from viscosity to curing profile to hardness and the presence or absence of solvents-plays a decisive role on the overall performance of the electronic system. DOWSIL™ products, due to their breadth of range and high performance under extreme conditions, emerge as benchmark solutions for critical applications.

Mascherpa has always supported engineers, designers and process managers in choosing the most suitable materials for the electronic protection of PCBs and complex circuits. If you would like to learn more about the technical specifications of silicone coatings or receive application advice on the needs of your industry, contact our experts: together we will find the most suitable solution for your project.