ARALDITE® 2080 and ARALDITE® 2081: low odor, non-flammable acrylic adhesives with outstanding bonding performance, low toxicity profile, and requiring no primer

ARALDITE® 2080 and ARALDITE® 2081 acrylic adhesives are a real innovation, as they are structural adhesives developed to provide high strength to which they are combined with important contents from the point of view of sustainability. Unlike traditional methyl methacrylate products, according to CLP legislation the new ARALDITE® adhesives are not classified as flammable. Their flash point >95°C allows lower environmental impact and lower costs of use, reducing exclusive safety, transportation and storage measures. With these stickers, many restrictions, such as tunnel transit, are overcome, enabling route optimization and thus CO2 emission reduction.

In Araldite® 2080 and 2081, improvements are also shown according to the GHS classification. In fact, since they are not corrosive products, the pictograms on the labels change from a “Danger” sign to a “Caution” sign. With less exposure to risk, operators will be able to use products with greater freedom, potentially avoiding wearing some inconvenient safety devices. These advantages are also reflected in the olfactory perception of the new products, which is up to 90 percent lower than with methyl methacrylates, making the work environment safer and more pleasant for those who experience it every day.

Finally, in most applications, ARALDITE® 2080 and ARALDITE® 2081 adhesives require minimal surface preparation, providing outstanding adhesion performance on a variety of substrates (plastic, composites, and metal) along with rapid curing at room temperature.

“Integrated” sustainability: ARALDITE® 2080 and ARALDITE® 2081 help companies achieve their sustainability goals

ARALDITE® 2080 and ARALDITE® 2081 adhesives contribute to increased productivity and reduced CO2 emissions. Their use supports companies to reduce costs without the trade-offs often associated with traditional adhesives, such as high odor, flammability, unfavorable toxicological profiles, the need for surface preparation, and energy to operate curing and/or post-curing hot cures.

Versatile and flexible for diverse applications

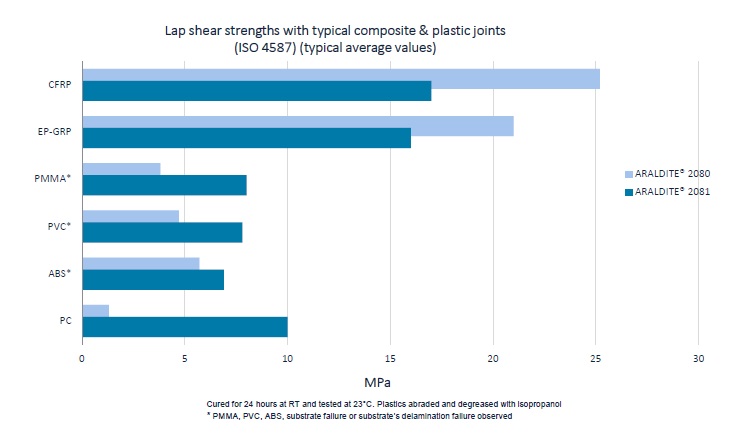

Two different technical products are available on the market today: ARALDITE® 2080, designed for bonding composites (GRP/CFRP) or metals (aluminum + steel), and ARALDITE® 2081, suitable for bonding engineering plastics (PMMA, PVC, PC, ABS).

Because of this versatility, we cover a wide range of substrates enabling numerous applications in various industries. The bondings are durable, high impact and impact resistance, and with elasticity greater than 50%. Bonding with ARALDITE® 2080 and ARALDITE® 2081 show high performance in poultice tests, detecting more than 12 MPA (measured after 7 days), a maximum continuous operating temperature of 90°C (ARALDITE® 2080) and 70°C (ARALDITE® 2081), respectively, as well as high tensile strengths > 25 MPA (ARALDITE ® 2080) and > 17 MPA (ARALDITE® 2081) and a modulus of 1,200 MPa (ARALDITE® 2080) and 800 MPa (ARALDITE® 2081). Data obtained in shear strength tests for various substrates such as metal, composite materials, and plastics are shown in the tables below as examples for typical bonding applications.

Main application areas for ARALDITE® 2080 and ARALDITE® 2081 adhesives

The advantages described for the new adhesives are best used in bonding in the transportation industry: for example, in the production of buses, trucks and trailers, the railroad industry, and the marine industry.

We believe there is also high potential in industrial applications, where bonding activities range from trim to profiles, fixtures, and even bonding of plastic parts for consumer electronics and in small and medium-sized household appliances.

More innovation on the horizon for Huntsman Advanced Materials

Our innovation and technology team is currently focusing its efforts on further developments and improvements, with the goal of making our low-odor, low-toxicity ARALDITE® adhesives increasingly efficient and available on a global scale.

We are developing solutions to reduce plastic waste that comes from the packaging of our adhesives. We are investigating the possibility of nimbly removing the bonding so as to facilitate maintenance and recycling operations. The use of “bio-attributed” raw materials and the study of recycling carbon fiber composite materials has already begun in our plants. All of these activities are clearly in line with an internal strategy to replace obsolete and inefficient materials with innovative materials so that our customers in turn can achieve their own sustainability goals.