Key points of the article

- Lubricating pastes reduce friction, wear and seizure under extreme conditions such as high temperatures and high loads.

- There are three main types: mounting, screw and fat, each with specific properties.

- Proper application requires clean surfaces and uniform coverage to ensure effectiveness and durability.

- MOLYKOTE® greasy pastes provide lubrication even in the absence of oil, protecting surfaces for a long time.

- Used in various industries, they improve performance and reduce maintenance of spindles, bearings and chains.

What is lubricating paste

Lubricating paste is a specialized compound containing high concentrations of solid lubricants dispersed in a base oil. Because of their high solids content, pastes are ideal for applications where metal-to-metal components experience friction under extreme conditions, such as heavy loads, high temperatures, or dusty or wet environments.

For different properties, lubricating paste provides several advantages:

- constant friction over time

- constant tension in the screws (due to the constant coefficient of friction)

- high load capacity

- prevents stick-slip

- prevents the unwanted formation of dirt

- ensures long service life without stress corrosion cracking

- facilitates maintenance by preventing seizure

- Protects mating surfaces, reducing the effects of oxide layer depletion (leading to rubbing, seizing, seizing and shearing)

- reduces embrittlement

Types of lubricating pastes

The 3 types of lubricating pastes are:

- Mounting pastes: facilitate assembly and prevent wear on contact surfaces.

- Screw pastes: ensure convenient tightening and the possibility of repeated disassembly with constant coefficients of friction.

- Greasy pastes: ideal for components subject to high loads and boundary friction conditions.

The pastes are specially formulated to withstand harsh conditions, to operate over a wide range of operating temperatures and to resist the effects of heavy loads, salt spray or other contaminants.

The pastes are designed to be a long-term solution: high loads of solid lubricants ensure that the solids stay in place, even under extreme conditions such as high temperatures or heavy loads.

Surface preparation and application of lubricating paste

All pastes are applied in the same way, regardless of the intended end use. For this reason, a specific process is followed for each type of use and application:

- Clean parts or threads as thoroughly as possible, removing any residual oil or debris. Standard cleaning methods for degreasing can adversely affect the performance of the paste, because they are used to remove lubricants as well.

- Apply the paste correctly to the contact surface and do not mix it with other oils or greases. Pastes can be applied with a canister. Canisters should be shaken vigorously before use, and likewise larger containers should be mixed. A brush or applicator can be used for application.

- Thoroughly coat surfaces: any excess lubricant will be pushed out of the contact area, and solid lubricants will remain long after the carrier oil has worn off. When applying to screws, make sure all threads are evenly covered. For large fasteners (>M30), it is recommended that paste be applied to both the fasteners and the nut to ensure complete coverage.

MOLYKOTE® Greasy Lubricating Paste.

The MOLYKOTE® greasy lubricating pastes., also known as grease pastes, contain a significant amount of solid lubricants such as molybdenum disulfide (MoS2), graphite and white solids. The base oils used may be mineral refined or synthetic, and act as carriers for solid lubricants.

These fatty pastes are formulated with soap-like concentrations that maintain the consistency of the paste, resulting in high resistance to drying and loss.

The lubricating paste offers excellent lubrication performance and high load-carrying capacity under boundary friction conditions.

Why choose MOLYKOTE® greasy lubricating pastes.

To achieve a state of hydrodynamic lubrication, conventional lubricating oils and greases require a minimum base oil viscosity and a minimum hydrodynamically effective speed. However, operating conditions such as excessively low speeds or intermittent operation may prevent hydrodynamic lubrication.

In such scenarios, the lubricating paste which contains solid lubricants with properties of “emergency operation” or of “dry running.” ensures the separation of mating surfaces to mitigate potential problems under these service conditions.

MOLYKOTE® greasy lubricating pastes are designed for conditions extreme tribologicalincluding slow movements e oscillating, loads heavy and high temperatures. They are superior to traditional oils and fats, which are unable to form films capable of prevent contact between the parts under these extreme conditions, resulting in wear or scratching.

MOLYKOTE® greasy lubricating pastes: advantages under harsh conditions

Under harsh conditions such as water-rich or chemically aggressive environments, greasy lubricating pastes, due to their properties, prevent:

- wear and tear

- friction

- the seizure

- corrosion and fretting corrosion in machines

- At ambient temperatures, carrier oil and solid lubricants provide lubrication

- At very high temperatures, the carrier oil evaporates, it separates or becomes decomposes. As a result, residual solid lubricants provide efficient lubrication through a strong lubricating film that adheres to the metal surface.

Unlike screw and assembly pastes, greasy lubricating pastes are used more generously over the contact area to provide long-lasting dynamic lubrication.

MOLYKOTE lubricating paste: the full range

MOLYKOTE®, a Mascherpa partner for more than 50 years, offers a range of specific lubricating pastes for various industrial applications, including:

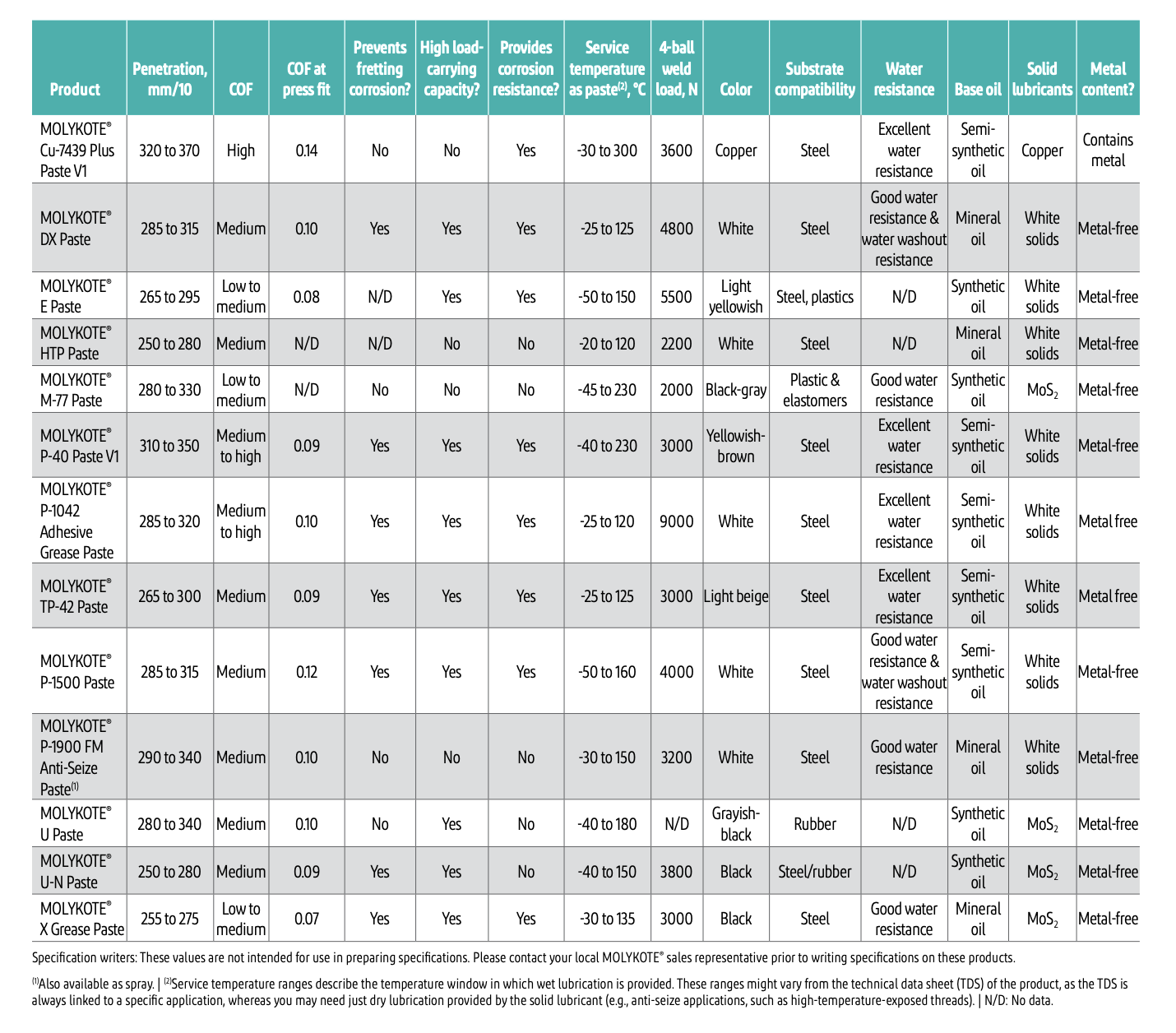

Typical Properties of MOLYKOTE® General Lubrication Pastes.

Case study: lubrication of lathe spindles

Lathe chucks are used to securely clamp workpieces in turning processes. An internal mechanism enables centered clamping by simultaneously closing the clamping jaws. Centrifugal forces during operation counteract the jaws until a workpiece can loosen.

The adhesive grease paste MOLYKOTE® P-1042 is designed to provide a safe and consistent level of clamping force. A careful selection of white solid lubricants provides a high level of clamping force and protection against vibration-induced fretting corrosion. Due to its viscosity and excellent adhesion to metal surfaces, this paste resists washout and does not dissolve or harden significantly when in contact with machining fluids.

The use of MOLYKOTE® P-1042 has reduced maintenance costs, extending tool life and lengthening maintenance intervals for lathe spindles.

Applications of MOLYKOTE® Lubricating Pastes.

MOLYKOTE® lubricating pastes are used in a variety of industries to ensure reliable performance, reduce friction and extend the life of mechanical components. Here are the main applications and recommended products:

- Lubrication of automobile seats with MOLYKOTE® DX Paste e MOLYKOTE® E Paste, for smooth and quiet adjustment.

- Worm Gears: MOLYKOTE® E Paste (mirror adjustment) and MOLYKOTE® P-1500 Paste (actuators, plastic worm assemblies) for smooth operation over a wide range of temperatures.

- Door locking systems and sunroof guides.: MOLYKOTE® P-1500 Paste for the doors and MOLYKOTE® E Paste for sunroofs, providing resistance to moisture and extreme temperatures.

- Lathe spindles: MOLYKOTE® P-1042 Adhesive lubricating paste e MOLYKOTE® TP-42 Paste, for adequate clamping forces, corrosion resistance and protection from modern machining fluids.

- Bearings: MOLYKOTE® P-1900 FM Anti-seize paste e MOLYKOTE® U Paste, for reduced friction, increased durability, and resistance to high temperatures and low rotational speeds.

- Chains of transport: MOLYKOTE® G-N Spray e MOLYKOTE® G-N Paste for metal mounts, offering long-term lubrication and reduced maintenance.

- Industrial plants: applications in high temperature and humidity environments, with resistance to vibration and corrosion, ensuring long-term operational efficiency.

- Sector food: MOLYKOTE® P-1900 FM anti-seize paste certified NSF H1, ideal for bearings and machinery in the food and beverage industries, ensuring safety and compliance with hygienic standards.

Conclusion

The MOLYKOTE greasy lubricating pastes are designed for extreme tribological conditions, ensuring high performance in harsh environments.

Thanks to their advanced formulation, they offer protection, efficiency and durability, contributing to reduced maintenance costs and optimized performance of mechanical components. For more information on products in the Molykote range. contact our Mascherpa experts, who will be able to offer specific advice for your every need.