Key points of the article

- Strategic Collaboration: Mascherpa supports PoliMI Motorcycle Factory in the development of electric racing motorcycles, providing the high-quality products behind the most innovative solutions.

- Advanced thermal management: solutions for heat dissipation in battery packs and electronic components critical to performance and safety.

- High-performance lubricants: anti-friction products such as Molykote® and Krytox™ improve mechanical efficiency and component life.

- Innovative composite materials: prepregs and structural adhesives optimize weight and strength for a lightweight, high-performance frame.

In the rapidly evolving world ofe-mobility, every technical detail can determine the success of a project. It is with this in mind that the collaboration between Mascherpa e PoliMI Motorcycle Factory for the development of prototypes of electric motorcycles for competition intended for MotoStudent International and to fuel growth and innovation in this area.

The fruit of partnership: the 3 Mascherpa solutions

Thanks to our experience in electric mobility, we have provided high-tech solutions in three key areas:

- Advanced systems of thermal management for the electronics and the battery pack.

- High-performance lubricants to reduce friction and wear in mechanical and structural components.

- Composite materials and structural adhesives to optimize the motorcycle frame and the entire structure.

Thermal management: thermal control for high-performance electric vehicles

One of the most critical aspects in the design of electric motorcycles high performance is the management of heat generated by electronic components and the motorcycle battery. Proper heat dissipation is essential to ensure reliability and safety in electric vehicles, especially in racing.

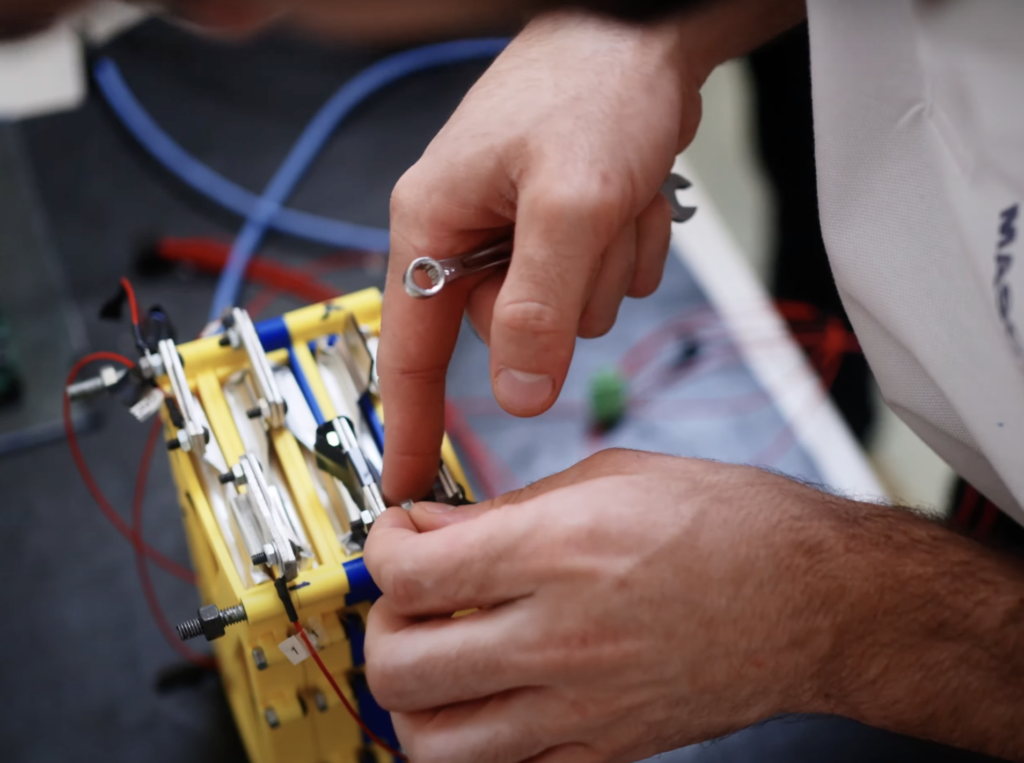

Mascherpa provided the PoliMI Motorcycle Factory team with excellent thermal conductive materials for the thermal management of the system, including:

- Thermal pads for the cells of the battery pack

- Heat-conductive glues to join cells to holders

- Coating for galvanic isolation of boards

- Thermal pastes for balancing board and inverter

- Thermo-conductive glues for bus-bar heat sinks

- Kapton to ensure the mechanical stability of the battery pack

These solutions made it possible to maintain stable operating temperatures of key components, contributing to the bike’s reliability under extreme conditions.

Electronic protection and thermal insulation

Sylgard 527 A+B is ahigh-performance two-component silicone geldesigned to provide electrical insulation and mechanical protection for PCBs and sensitive electronic components. It is ideal for boards used ine-mobility and compact devices, it keeps stress on electronic components low.

Dissipation and thermal insulation

DOWSIL™ EE-3200 A+B is a lubricant designed to protect the battery packs, it offers high thermal conductivity and low viscosity. Perfect for electric motorcycles high-performance bikes, allows for EV charging safely while maintaining efficiency even in critical environments.

Anti-friction lubricants: mechanical efficiency in electric mobility

In the area of electric mobility, reducing friction in mechanical systems is critical to improving energy efficiency and component durability. Mascherpa has selected a range of anti-friction coatings ideal for use in motorcycle prototypes and competition motorcycles.

Molykote® D-321 R: solid antifriction coating

Molykote D-321 R is a MoS₂-based dry coating that forms a solid film ideal for high-stress joints and surfaces. Perfect for dusty environments and extreme load conditions, it improves the smoothness of moving parts in the electrical motion.

Protection and reliability with Molykote products

Molykote M-77 is alubricating paste with MoS₂ and graphite, which withstands extreme temperatures and reduces wear even under high vibration. It is ideal for thermal management mechanics in electric vehicles.

Krytox™ GPL 205: stable lubrication in critical conditions

Krytox™ GPL 205 is a fluorinated grease used for joints and bearings in high temperature environments. Stable up to 260°C, it provides protection in the most critical areas of the motorcycle frame and improves overall system reliability.

Composite materials: light weight and strength for electric racing motorcycles

Low weight and high rigidity are essential requirements in the construction of prototype electric motorcycles for competition. Mascherpa supplied composite materials advanced composites for the construction of the motorcycle frame, fairing and other structural elements.

Among the solutions adopted by the PoliMI Motorcycle Factory team:

- Prepregs made of high quality carbon fiber

- Araldite®structural adhesives for safe and lightweight bonding

- Materials for Wet Filament Winding, ideal for shaped and strong parts

The use of these composite materials made it possible to optimize the balance between weight and strength, improving the handling and on-track performance of the electric motorcycle.

Mascherpa’s solutions for the e-mobility of the future

The collaboration with the team PoliMI Motorcycle Factory is a virtuous example of how materials expertise can accelerate innovation in the field ofe-mobility. The products we supplied covered every aspect of motorcycle design: from the EV charging safety to battery pack protection and from mechanical efficiency to structural lightness.

A concrete contribution to the development of solutions for the creation of electric racing motorcycles, the result of the encounter between passion for technology and knowledge of materials. A commitment that we at Mascherpa carry on through the project NEXT, designed to support valuable young realities.

Learn more on Mascherpa’s NEXT page or contact us for information about the products mentioned and how we can support your projects in electric mobility.