Key Points

- Proper industrial lubrication is crucial for the reliability, operational continuity, and longevity of machinery.

- Every application, gears, bearings, chains, and threaded connections, requires maintenance lubricants, specific to each mechanical and environmental condition.

- Oils, greases, and lubricating pastes allow control of friction, temperature, and wear, reducing machine downtime and maintenance costs.

- Proper lubrication prevents critical issues such as seizure, corrosion, pitting, and deformation of components.

- All the solutions described are part of the Molykote range of industrial lubricants, supported by Mascherpa’s application expertise.

In the context of industrial maintenance, the correct selection and application of oils, fats e pastes lubricants is a determining factor to ensure reliability, operational continuity e longevity of machinery.

Industrial lubricants not only reduce friction, but also directly contribute to temperature control, corrosion protection, wear prevention, and reduction of machine downtime.

From plastic gears used in automatic machines, to bearings subjected to extreme thermal conditions, to chains, open gears, and threaded connections, each application requires specific solutions developed to operate under well-defined mechanical and environmental conditions.

In this article, we analyze five key applications of industrial lubrication, highlighting the role of maintenance lubricants in improving the performance of industrial plants.

Lubricants for plastic gears

Lubricants for plastic gears are crucial in applications where precision, quietness, and operational continuity are required, such as coffee machines, vending machines, and dosing systems.

Proper lubrication allows reduction of friction between teeth, limiting the overheating and preventing mechanical damage that can compromise the correct functioning of the gear.

Maintenance lubricants play a key role in controlling the transmitted torque, preventing damage to the tooth flanks that can lead to deformations and cracks over time. At the same time, compatibility with plastics, particularly with POM, is essential to not alter their mechanical properties and ensure consistent performance.

In food applications, compliance with FDA 21 CFR 178.3570 and NSF H1 allows use even in the presence of accidental contact with food, without risk of contamination. The result is greater machine longevity, a reduction in downtime, and a decrease in maintenance costs.

Lubricating pastes for screws and threaded connections

Threaded connections are designed to allow repeated disassembly and precise reassembly, but their correct functioning depends on friction coefficient control. In the absence of adequate lubrication, the tightening is imprecise and the tension applied to the screw is not uniform.

Lubricating pastes for screws and threaded connections allow:

- achieving the correct tightening torque;

- avoiding undesired leaks due to uncontrolled tensions;

- preventing seizure caused by high temperatures and mated surfaces;

- protecting against corrosion due to chemical and atmospheric agents;

- facilitating disassembly even in the presence of different thermal expansions between flange and screw.

Thanks to the high concentration of solid lubricants, these pastes create a stable protective film that remains in place even under high loads, ensuring a constant friction coefficient. This allows maintenance control, reducing the risk of breakage and increasing the reliability of the connection over time.

Chain lubricants

Industrial chains offer high efficiency, robustness, and the ability to operate in hostile environments, but these performances can only be maintained through adequate lubrication. Industrial maintenance lubricants directly affect the mechanical behavior of pins, bushings, and consecutive joints.

Proper lubrication allows:

- controlling the friction coefficient, avoiding power losses;

- managing the tension between consecutive joints, preventing unexpected loads;

- protecting pins and bushings from mating surfaces and temperature;

- avoiding chain elongation;

- protecting against harsh environments and chemical agents, preventing rust;

- reducing the formation of pitting on the sides of the links;

- limiting energy consumption and temperature increase.

The use of oils, greases, and anti-friction coatings (AFC) allows cushioning of impact forces and maintaining a constant friction coefficient, increasing the chain’s lifespan and reducing downtime and maintenance costs.

Lubricating pastes and greases for open gears

Open gears are used for the efficient and economical transmission of power and for their high load capacity, but they are directly exposed to contaminants and harsh operating conditions. Lubrication is therefore essential to preserve their functionality and longevity.

Lubricating pastes and greases for open gears allow:

- controlling the friction coefficient, maintaining high efficiency;

- ensuring a constant transmitted torque between gears;

- protecting against excessive loads and temperatures;

- preventing deformations and breakages of gears;

- isolating surfaces from dust and contaminants, avoiding abrasions;

- limiting the formation of surface pitting on teeth.

The combination of base oil, thickeners, and solid lubricants creates a resistant and adherent film, capable of protecting against wear and corrosion, allowing more controlled maintenance management and reducing the risk of unexpected failures.

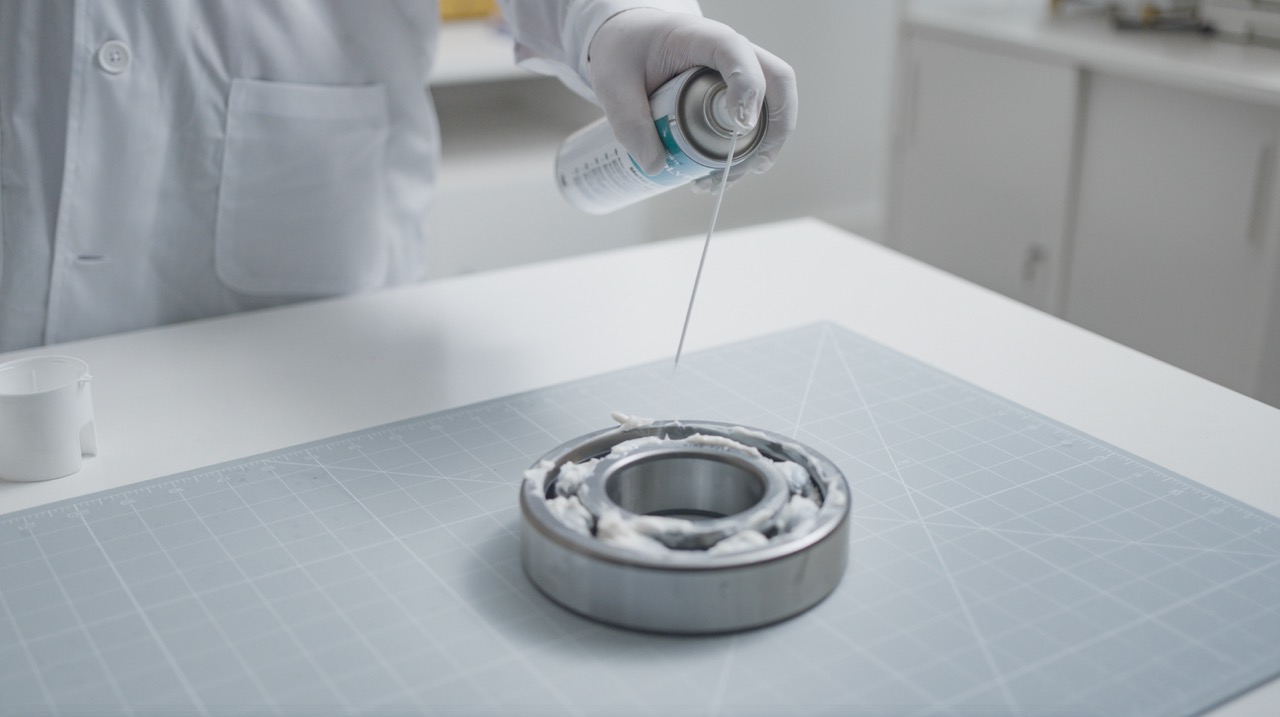

Lubricants for bearings

The correct functioning of bearings directly depends on adequate lubrication in terms of product, quantity, and compatibility. Improper lubrication management is among the main causes of failure.

The most common problems related to bearing lubrication include:

- use of inadequate lubricant;

- insufficient or excessive lubricant quantity;

- mixing of incompatible lubricants;

- contamination from external elements.

The purpose of lubrication is to create a thin film that separates rolling and sliding surfaces, avoiding metal-to-metal contact. If properly applied, lubrication:

- reduces friction and abrasion;

- limits heat generation;

- extends the bearing’s service life;

- prevents rust and corrosion;

- protects against contamination from solvents and external agents.

Formulations based on polytetrafluoroethylene (PTFE) and perfluoropolyether oil (PFPE) allow reliable operation under extreme conditions, from -70°C to over 300°C, maintaining constant protection and performance.

Lubrication as a key element of industrial machinery maintenance

Industrial lubrication is a strategic element of maintenance and requires in-depth knowledge of applications, operating conditions, and wear mechanisms involved. From the lubrication of plastic gears, bearings, chains, open gears, and threaded connections, each choice directly impacts reliability, safety, and production continuity.

Through application experience and technical support, Mascherpa assists companies in selecting the most suitable lubricants for effective and controlled industrial maintenance.

To explore individual application areas, contact Mascherpa experts or visit the section Mascherpa Expert and discover the dedicated technical content.