Key Points

- Mascherpa will be present at JEC World 2026 as an exhibitor together with the European partners of the DGE group.

- The fair will take place from March 10-12, 2026 at Paris Nord Villepinte, the main global event dedicated to composite materials.

- At the DGE–Mascherpa booth (Hall 6–Stand G74), complete solutions for composite materials will be presented, with a focus on Huntsman Araldite epoxy resin systems for composites.

- Mascherpa goes beyond material supply, offering technical support throughout all phases of composite material use.

- A process-oriented approach to applications and markets, developed through direct experience and real projects.

JEC World is the reference international trade fair for the industry of composite materials and structural solutions advanced. Every year it brings together manufacturers, designers, engineers and decision makers from around the world to discuss innovation, production processes and industrial applications.

The JEC World 2026 edition will take place from March 10-12 at the Parc des Expositions Paris Nord Villepinte, with three days dedicated to exhibitions, technical meetings and global networking.

In this context, Mascherpa will be present as an exhibitor within the DGE stand, together with European partners, including Samaro and Antala.

Where to find us

- When: March 10-12, 2026

- Where: Paris Nord Villepinte

- Hall: 6

- Stand: G74 – DGE Stand

At the stand it will be possible to discuss with specialized technicians the main topics related to composite materials, production processes and high-performance industrial applications.

Composite material solutions presented at the DGE – Mascherpa stand

At the Mascherpa stand, composite material solutions based on epoxy resin systems ARALDITE® by Huntsman Advanced Materials will be presented.

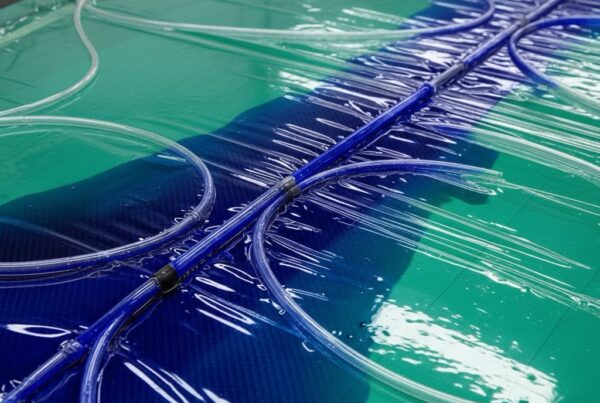

The solutions on display are designed for the main composite processing processes and for use with reinforcement fibers such as glass fiber and carbon fiber.

The epoxy resin systems for composites ARALDITE® find application in various industrial sectors, including aerospace, automotive, marine, sports, energy and general industry, offering a balance between performance, reliability and process compatibility.

The Mascherpa value: technical support throughout the entire composite process

The Mascherpa approach to composite materials is based on a vision of technical support throughout all phases of the process, which goes beyond the simple supply of materials.

Alongside ARALDITE® systems, Mascherpa supports composite material projects by integrating:

- core materials such as Nidaplast and 3D-Core™;

- SAERTEX® reinforcement fabrics;

- consumable materials for molding by Diatex.

Mascherpa offers solutions for the main production processes, including infusion, RTM, wet lay-up and filament winding. An approach developed on real applications in sectors such as aerospace, marine, automotive, energy and industry, with the objective of ensuring consistency between materials, process and final application.

Come visit us at JEC World 2026

If you operate in sectors where composite material applications are fundamental and you wish to discuss concrete solutions for the design, production and assembly of composite structures, come visit us at the DGE stand at JEC World 2026.

Our team will be available to discuss real applications, production processes and criteria for selecting materials most consistent with your needs. If you want to learn more about the Mascherpa approach to composite materials, you can:

- Visit our Mascherpa Next page, to see how we have applied our approach and our products in real projects.

- Visit our Mascherpa Expert page, for dedicated insights on composite topics.

- Contact our Mascherpa experts for more information on composite topics and the solutions best suited to your applications.