How to choose the correct resin for effective resistance in end-use environments

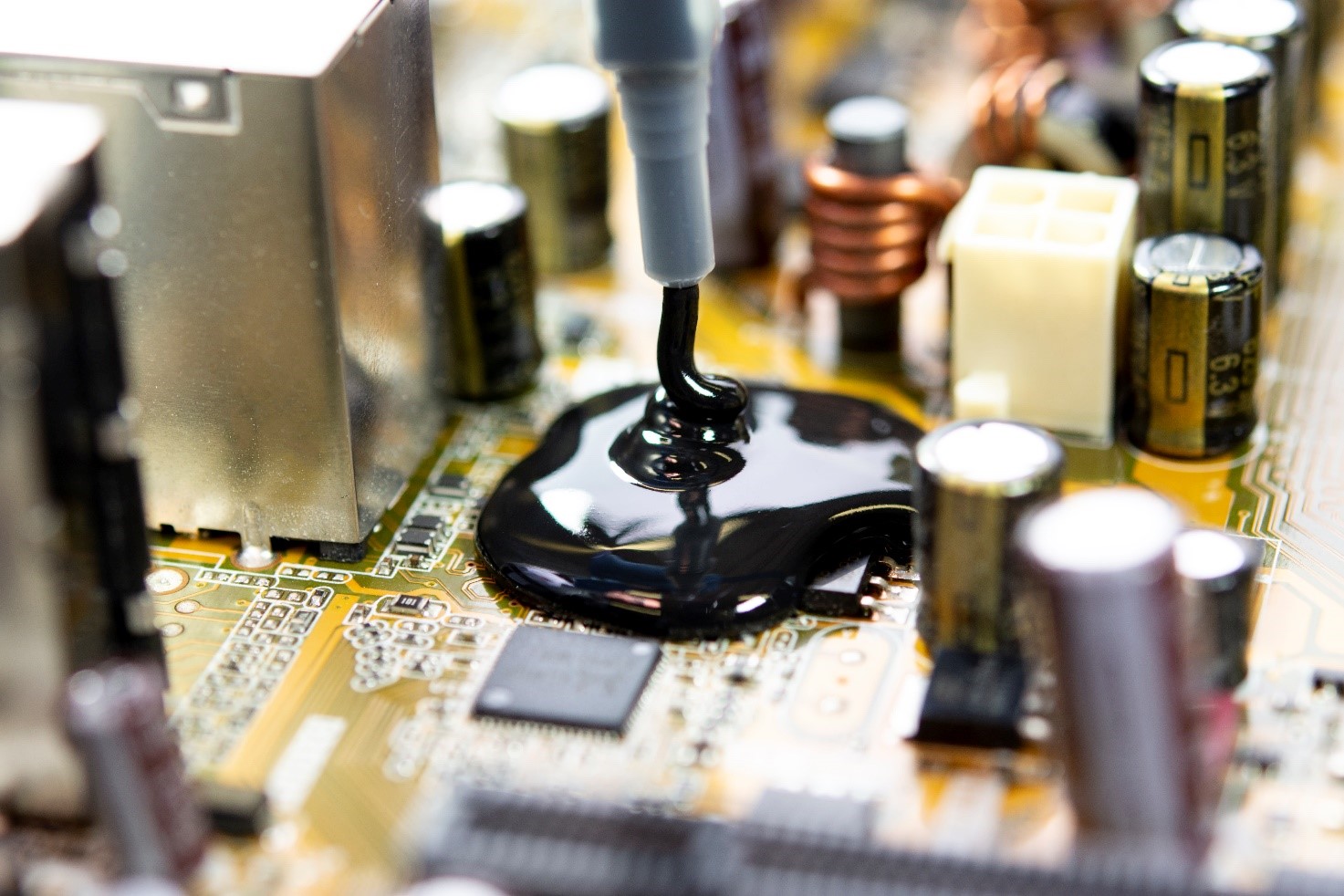

As we begin the resin selection process, we will always have to consider what strength we would like to have in the end-use environments, so let’s take a closer look at the basic chemistries of encapsulation resins and examine how each type of resin offers individual properties that can be leveraged to maximize performance in a wide range of environmental conditions.

A good starting point is to look at the archenemy of electrical and electronic devices, the dreaded “humidity.” In addition to producing short circuits, moisture also causes corrosion, which leads to premature deterioration of components. So which resin is best suited to combat moisture? Polyurethane resins!

These are usually supplied as two-part products that achieve the desired cure when mixed, and provide excellent moisture resistance as well as excellent electrical insulation, flexibility, and good adhesion to most substrates, both metal and plastic.

For more intense moisture resistance, there are polyurethane resin systems that provide exceptional resistance to seawater and extreme temperatures, making them an ideal choice for marine applications such as sensor encapsulation.

Another good example of a polyurethane resin encapsulated component that requires maximum protection against outdoor water ingress is LED lighting; these resins are also optically clear and UV stable, making them ideal for this task.

There are some epoxy resins that offer good moisture resistance, as well as fast curing, hardness and high stability, particularly in variable temperature environments. These epoxy resins adhere well to most substrates, even difficult substrates with very low surface tension, such as PTFE, providing a watertight encapsulation.

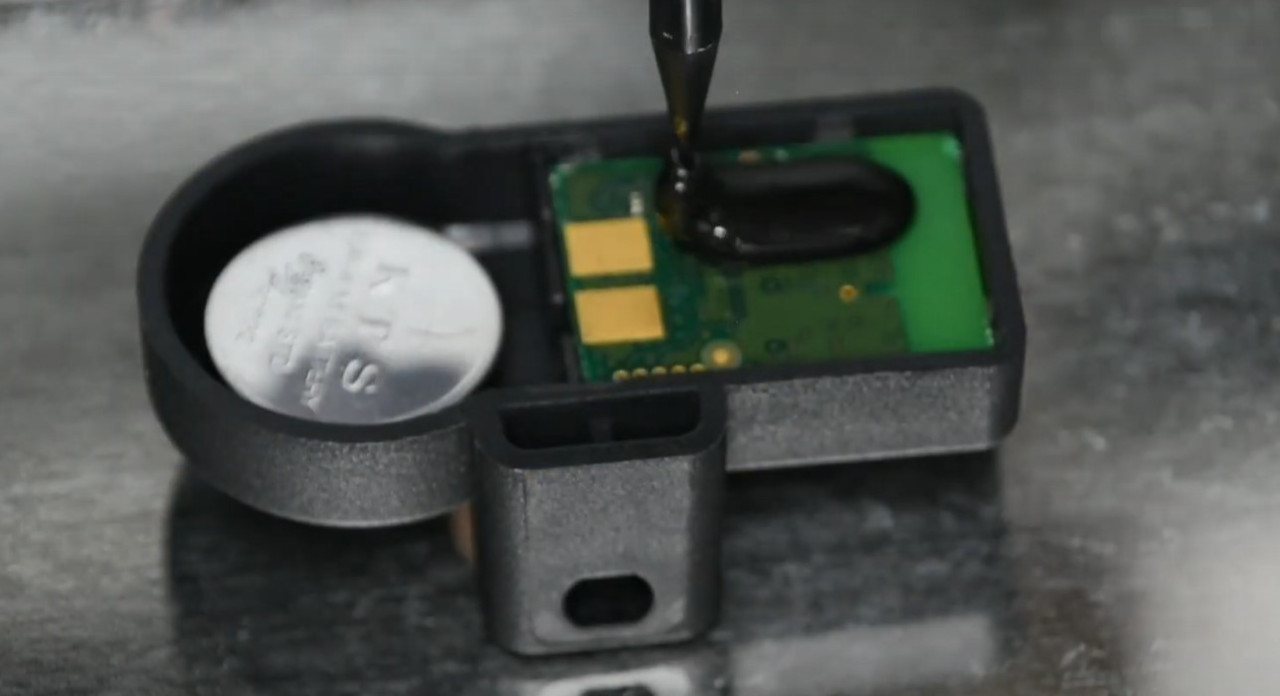

Electrolube was called upon to provide a protection solution for a smart parking lot, where dome-shaped sensor protection was needed within the parking lot floor. The sensors not only had to withstand the cars driving over them and be resistant to extreme temperatures and water ingress, but also to allow effective RF communication so that the signal could travel through the sensor and the resin.

The customer initially approached Electrolube following problems with the unit’s current material not being strong enough to withstand the impact of cars passing over it. In addition, the surface energy of the housing material was too low to allow good wetting of the existing resin and consequently prevented good adhesion. This caused the unit material to bend, and despite reasonable resin adhesion, they found delamination and water ingress inside the unit. The desired resin had to be of low viscosity to fill all voids in the small unit, show good adhesion to the unit material, and provide protection at low temperatures during winter and high temperatures during summer.

As a result, the unit design, hardness and housing material were changed. Electrolube provided UR5118 polyurethane resin to avoid RF interference and provide a dielectric constant of 3-4 @50Hz. UR5118 has a viscosity of 2300cP @ 23°C and 860cP @ 60°C that ensures sufficient flow in small spaces. It has a wide temperature range from -60 to +125°C and a low exotherm (<35°C). The reformed unit was tested with the new UR5118 resin and passed all tests.

You may also need to protect electrical or electronic components from encountering chemicals, including acids, alkalis, solvents and other substances that pose a threat to delicate circuits and components. Chemical resistance is the territory of epoxy resins, although some of the stronger polyurethane products, as well as some silicone-based formulations, will provide some degree of protection. Epoxy-based products are effective for protecting electrical/electronic units that are subjected to frequent or permanent immersion in solvents such as brake fluid, antifreeze, unleaded gasoline, and cellulose thinners.

If protecting components from mechanical shock and vibration is a concern, then a more flexible cured resin is probably the best solution because it adds a level of compliance that helps insulate potted components against adverse mechanical movement. In addition to their moisture-resistant properties, polyurethane resins also provide this desired level of flexibility and thus are often the first choice for shock and vibration protection. Silicone resins also offer excellent flexibility and, in addition, tolerate high operating temperatures.

Thermal shock can have a devastating effect on electronic components, shortening their operational life at best and completely destroying them at worst. The negative effects of thermal stress can be greatly ameliorated by using two-component epoxy resins with a low coefficient of thermal expansion (CTE), which are the best solution for those applications that are subjected to severe temperature cycling or are likely to experience thermal shock. In addition, some epoxy resins also provide the bonus of flame retardant technology.

Finally, it is worth mentioning that in addition to providing all the protections listed above, opaque potting and encapsulating resins also conceal what lies beneath. This could provide an effective solution against counterfeiters or those who wish to copy a circuit layout, helping you to protect your intellectual property.