Reducing “range anxiety” for Audi’s first all-electric SUV

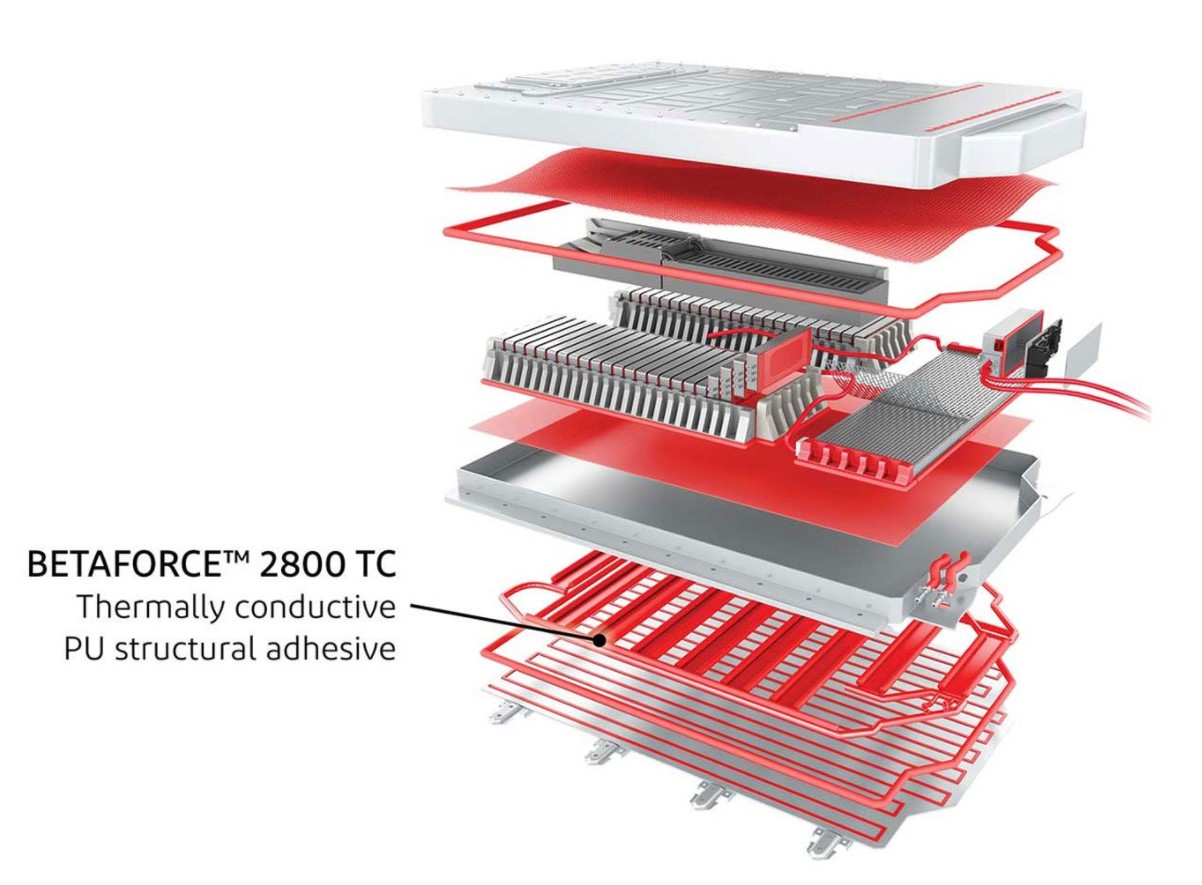

BETAFORCE ™ 2800 TC two-component heat-conductive adhesives have been optimized for Audi e-tron.

DRAFT

DuPont worked with Audi engineers to develop an adhesive material that can support super-fast charging of Audi e-tron, Audi’s first all-electric sport utility vehicle (SUV). In addition to the thermal management capabilities, the thermo-conductive adhesive has also been optimized to help achieve best-in-class driving performance, extend module life cycle, and improve performance.

CHALLENGE

One of the biggest challenges in battery design for plug-in hybrid (PH) and electric vehicles (EVs) is the thermal management of the battery pack. Battery components should operate in the optimal temperature window of 25°C during operation and below 60°C during charging.

Many drivers put off buying an electric car because of limited driving range and battery life. Audi’s goal was to ensure sufficient daily capacity without sacrificing performance.

Drivers fear delays because their electric vehicle takes too long to recharge. Audi’s e-tron SUV must be capable of super-fast charging without generating excessive heat.

SOLUTION

Audi’s new 95 kWh e-tron battery, optimized with BETAFORCE ™ 2800 TC that conducts temperature during both charging and driving, offers a range of more than 400 kilometers and supports 150 kW super fast charging, freeing drivers from range anxiety.

With a quieter electrical transmission, the vibration inhibition properties of BETAFORCE ™ 2800 TC are also important for user satisfaction. Handling is also improved by placing the battery glued into the cockpit floor, creating a low center of gravity.”

Production advantages are possible because of the good behavior of the adhesive in industrialization processes, which enables the rapid dispensing necessary to support high-volume production. “.

BETAFORCE ™ 2800 TC helps manage the potential temperature difference between the cooling unit and the cooling plate.

BETAFORCE ™

BETAFORCE ™ 2800 TC is the adhesive that has enabled the development of thermo-conductive adhesion for plug-in hybrid and electric vehicles.

- Good adhesion to plastics, composites, and painted surfaces

- Good adhesion to coated metal surfaces

- Primerless adhesion on many composite materials

- Optimized for accelerated adhesion at high temperatures

- High mechanical strength and high elongation at break

BETAFORCE ™ polyurethane adhesives are two-component composite adhesives. Formulations vary according to the vehicle manufacturing process and reflect variables such as viscosity, application temperature, conductivity, cure time, elasticity, strength and temperature.